Stirring device for constructional engineering

A mixing device and construction engineering technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as poor mixing effect and inability to realize material turning, and achieve the effect of improving mixing effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

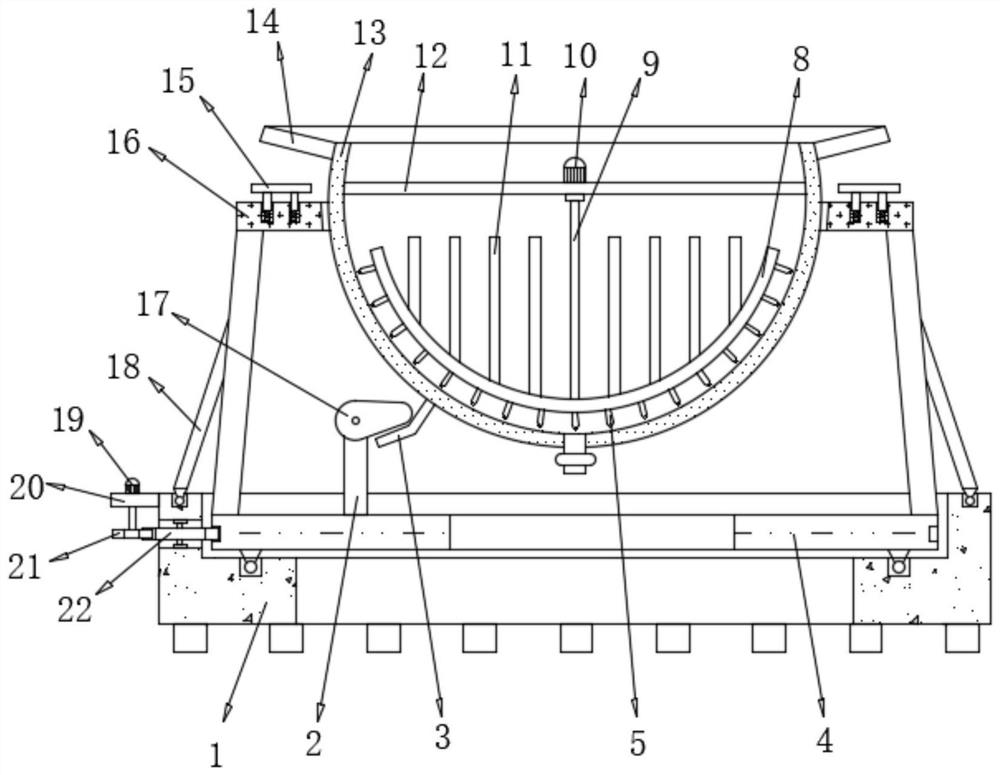

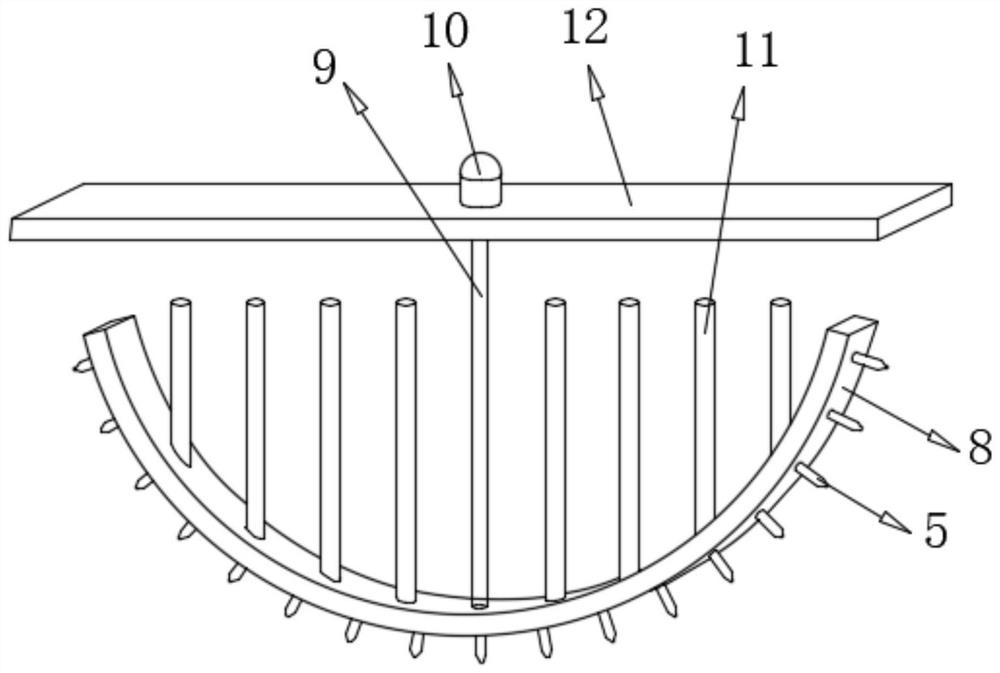

[0026] refer to Figure 1-2 , a stirring device for construction engineering, comprising a base 1, the top of the base 1 is slidably connected with a rotating plate 4, and the top of the rotating plate 4 is connected with a column through fastening bolts, and the top of the column is connected with a mounting ring 16 through fastening bolts , the top middle position of the mounting ring 16 is provided with a first perforation, and the inner walls of both sides of the first perforation are connected with the same stirring tank 13 through bearings, the inside of the stirring tank 13 is provided with a stirring mechanism, and the outer wall of one side of the stirring tank 13 The bottom is connected with the side wings 3 by fastening bolts, and the top of the rotating plate 4 is provided with a cam mechanism. While stirring the materials in the stirring tank 13 through the stirring mechanism, the side wings 3 can be knocked back and forth through the cam mechanism, thereby driving...

Embodiment 2

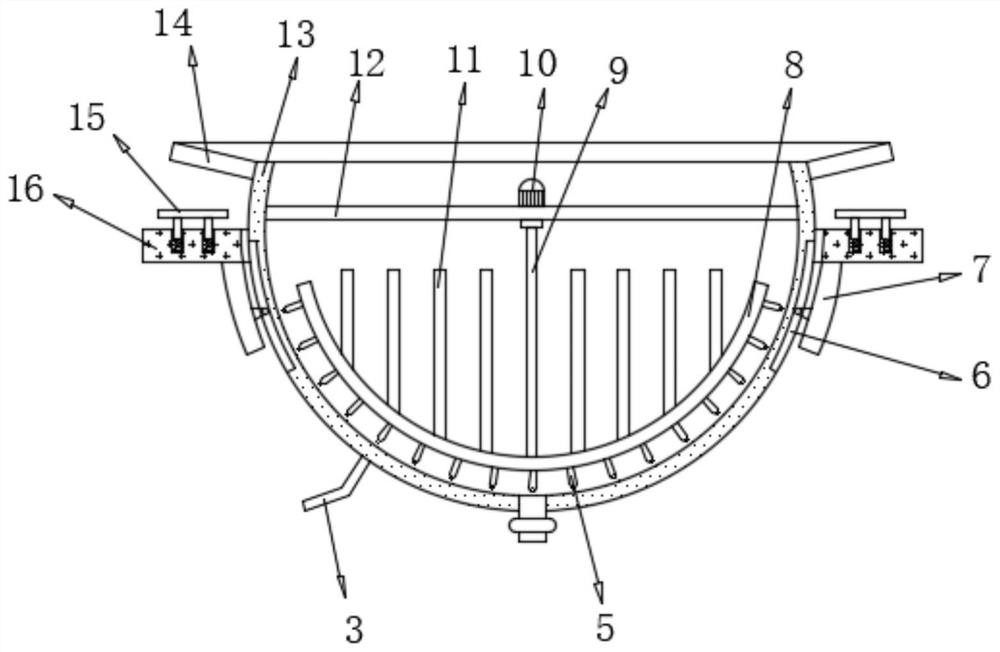

[0037] refer to image 3 , a stirring device for construction engineering. Compared with Embodiment 1, the bottom of the installation ring 16 is connected with extension plates 7 by fastening bolts along both sides of the first perforated opening, and the two extension plates 7 are close to the stirring One side of the tank 13 is connected with projections by fastening bolts, and the outer walls of both sides of the stirring tank 13 are provided with guide grooves 6 , and the outer diameter of the projections matches the inner diameter of the guide grooves 6 .

[0038] Working principle: While stirring the materials in the stirring tank 13 through the stirring mechanism, the cam mechanism can be used to reciprocate and strike the side wings 3, thereby driving the stirring tank 13 to swing back and forth, so that the materials are stirred with the stirring tank 13 at the same time. , to improve the stirring effect, the stirring motor 10 can be used to drive the stirring paddle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com