Blank forming mold

A blank forming and mold technology, applied in the field of molds, can solve problems such as poor mold fine-tuning and slag cleaning efficiency, low mold processing qualification rate, and narrowing of mold tooth slots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

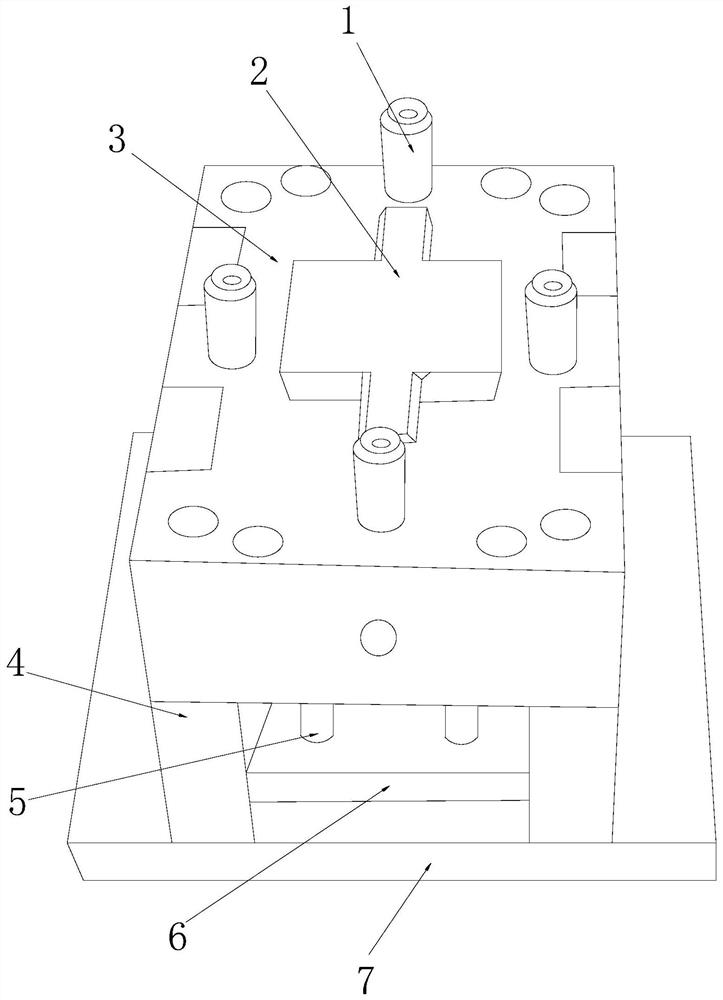

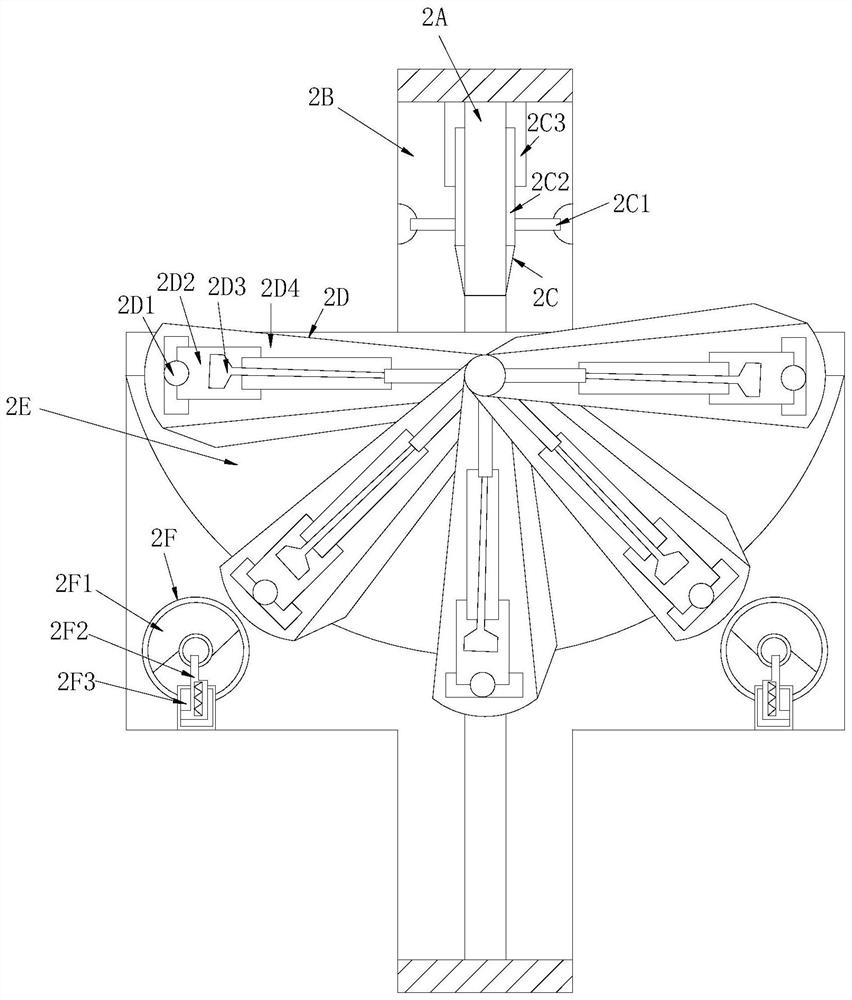

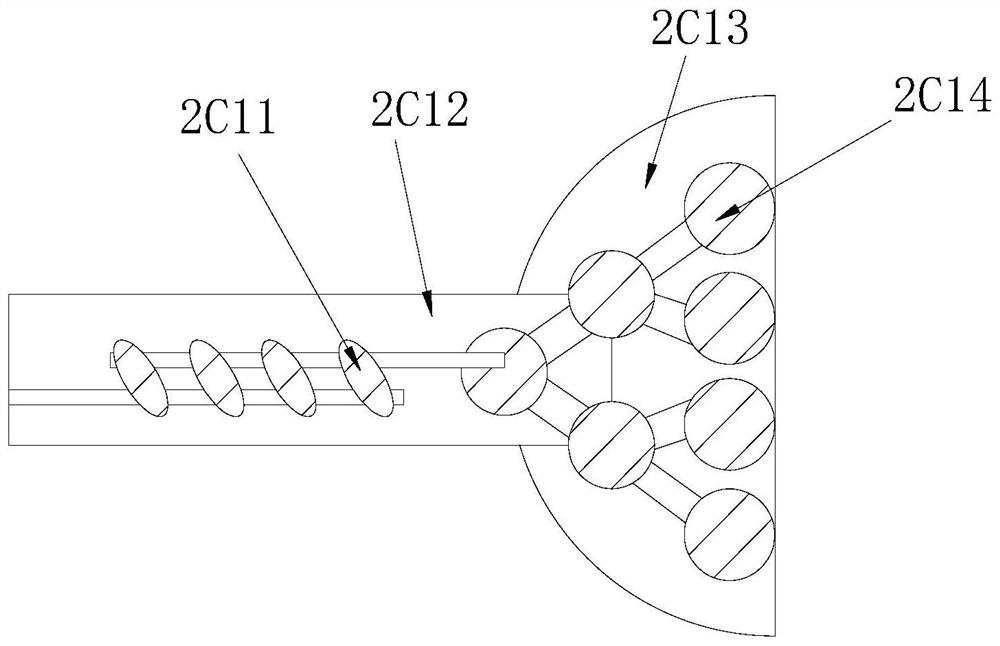

[0032] see Figure 1-Figure 6, the present invention provides a mold for forming blanks, the structure of which includes: a lock pin column tube 1, a cover mounted shaving rack mold groove 2, a parting surface groove block 3, a pillar plate 4, a cylinder rod 5, and a demoulding bottom cushion block 6. The base plate 7, the cover-mounted shaving frame mold groove 2 is nested on the top of the parting surface groove block 3 and is on the same horizontal plane, and the parting surface groove block 3 passes through the lock pin column tube 1 and the pillar The plates 4 are snapped together and are perpendicular to each other. The parting surface groove block 3 is mechanically connected with the demoulding bottom pad 6 through the cylinder rod 5 and is parallel to each other. The demoulding bottom pad 6 is closely attached to the base plate 7 and on the same horizontal plane, the cover-mounted shaving frame mold groove 2 is provided with an I-shaped long shaft rod 2A, a middle fram...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a mold for blank forming, other aspects are the same as in Example 1, the difference is:

[0040] see figure 2 , the pad support wheel frame seat 2F is composed of a pad support wheel disc 2F1, a shock-isolation spring clamp plate 2F2, and a square frame seat 2F3, and the cushion support wheel disc 2F1 is nested on the top of the shock-isolation spring clamp plate 2F2. The shock-isolation spring clip 2F2 is inserted and embedded on the top of the square frame seat 2F3 and is on the same vertical plane, and the shock-isolation spring clip 2F2 is pressed against by the support wheel 2F1 to form a load-bearing settlement force to ensure the edge of the frame cover Avoid wear and tear of the knife and improve the protective effect of the inner frame.

[0041] see Figure 6 , the shock-isolation spring clamping plate 2F2 is composed of a knuckle reinforcing rib 2F21, a lock pin clamping plate 2F22, a cross bar 2F23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com