A Calculation Method of Fuel Heat Generation at the Nozzle Hole of High Pressure Common Rail Injector

A high-pressure common rail and calculation method technology, which is applied in the direction of machines/engines, fuel injection control, electrical control, etc., can solve problems such as fuel temperature rise and fuel injection quantity prediction accuracy drop, and achieve accurate and precise prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

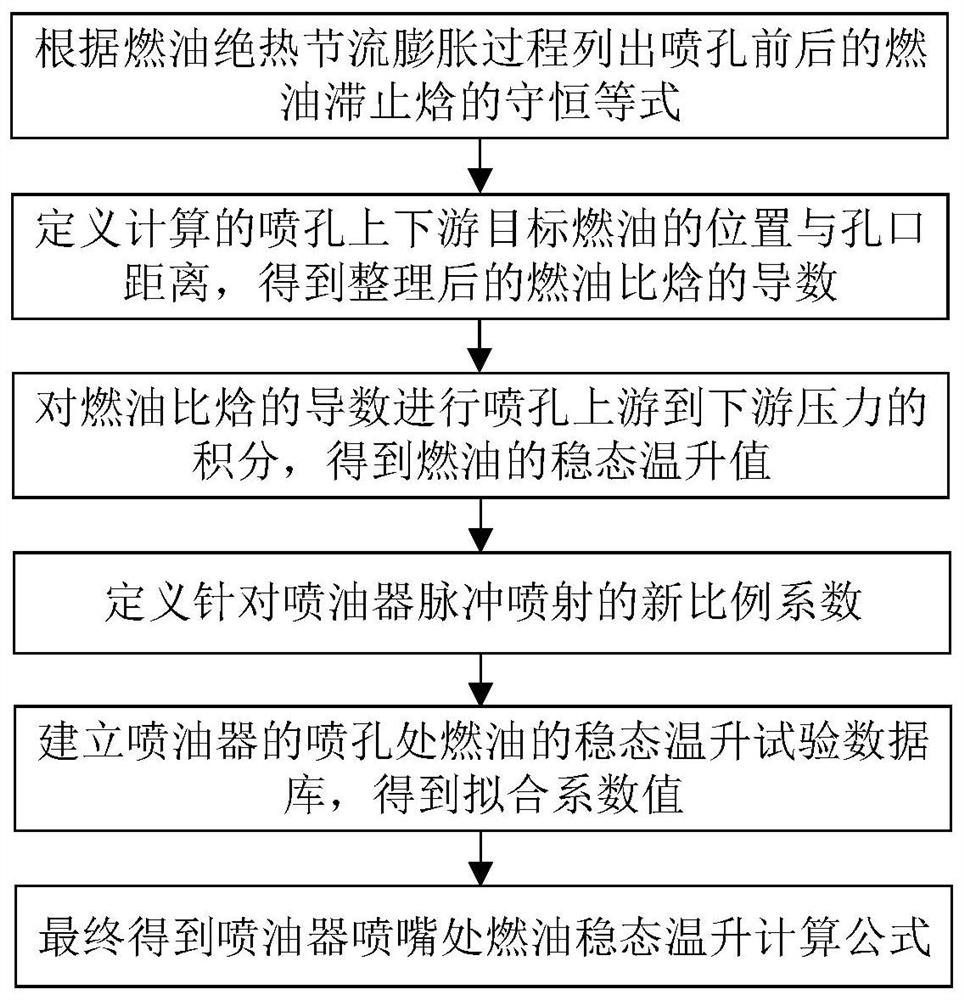

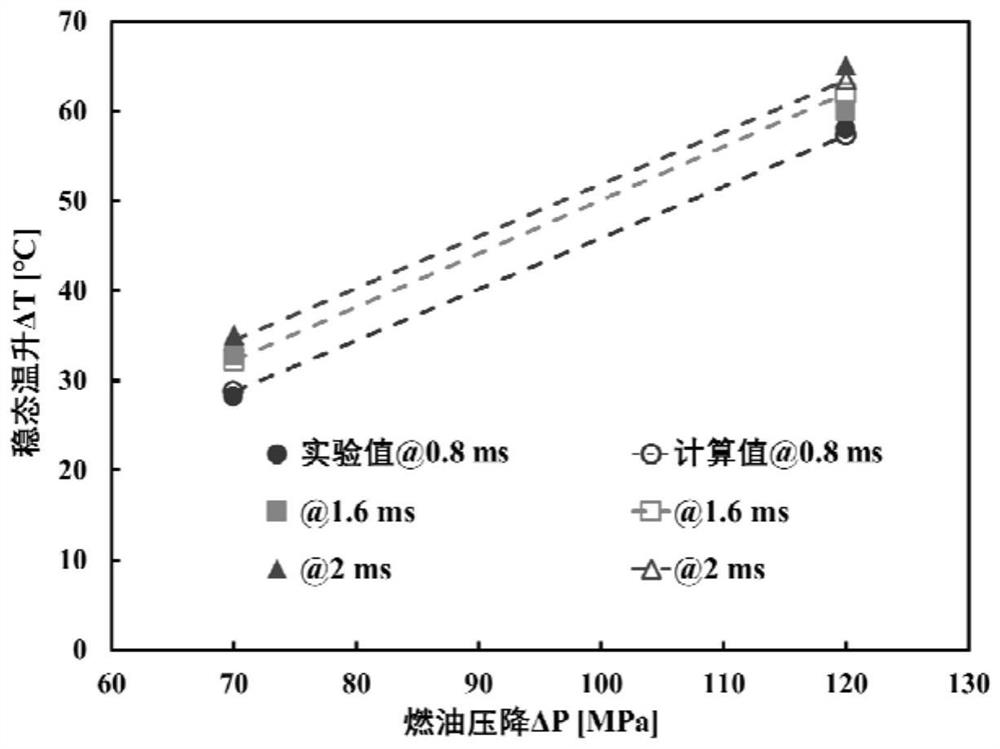

[0024] combine Figure 1-2 , the present invention is a method for calculating the steady-state temperature rise of fuel at the orifice of a high-pressure common rail injector, and the specific process includes:

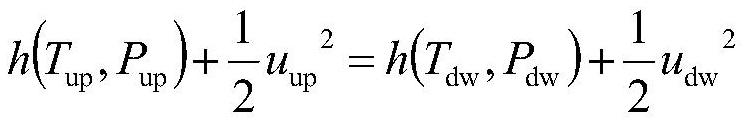

[0025] (1) Assuming that the process of high-pressure fuel flowing through the nozzle hole in the common rail injector is an adiabatic throttling expansion process, according to the first law of thermodynamics, when there is no external work, the fuel stagnation enthalpy is conserved before and after the throttle hole:

[0026]

[0027] In the above formula, h is the specific enthalpy of fuel, which is a function of temperature T and pressure P, u is the flow velocity of fuel, and the subscripts up and dw represent the upstream and downstream of the injection hole, respectively.

[0028] (2) Define the distance between the upstream and downstream tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com