Self-balancing structure for medium-high pressure blast load generator

An explosive load, self-balancing technology, applied in the testing of machine/structural components, instruments, scientific instruments, etc., can solve problems such as inability to balance dynamic loads, and achieve the effect of simple structure, clear function, and precise installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention is described with reference to the drawings and specific embodiments.

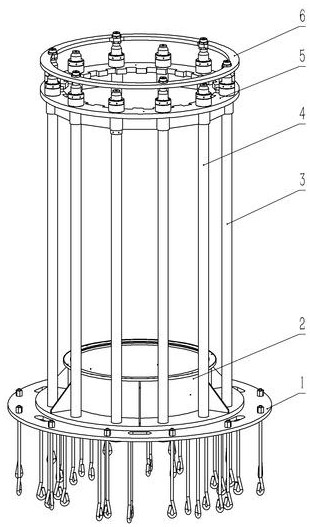

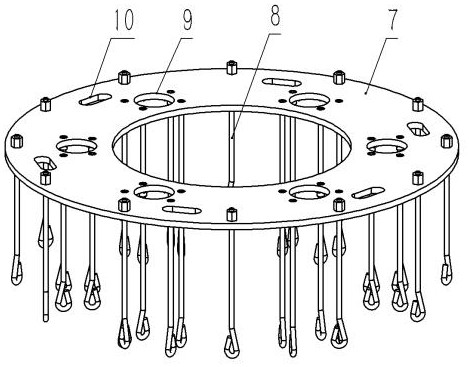

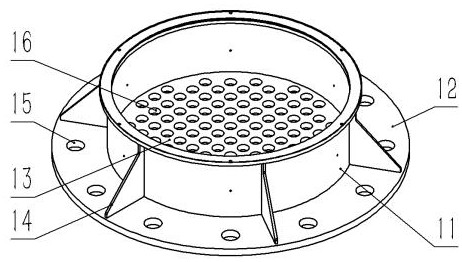

[0026] Such as figure 1 As shown, a self-balancing structure for a medium-high pressure explosion load generator mainly includes the assembly tooling plate 1 at the bottom of the experimental section, the cylinder base 2 of the experimental section, the long tie rod assembly 3, the short tie rod assembly 4, and the lower meshing tooth plate of the quick-opening door 5. The fixing ring 6 of the opening and closing assembly. The bottom assembly tooling plate 1 of the experimental section is pre-embedded in the foundation structure at the bottom of the explosive load generator; the cylinder base 2 of the experimental section is fixed above the bottom assembly tooling plate 1 of the experimental section; the long pull rod assembly 3 The short tie rod assembly 4 is alternately and evenly distributed circumferentially on the periphery of the explosive load generator; the bottom end of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com