Method for manufacturing micropores in metal plate

A metal plate and micro-hole technology, applied in metal processing equipment, manufacturing tools, forming tools and other directions, can solve the problems of lack of popular application, low processing efficiency, high cost, low process requirements, improved processing efficiency, and scrapped low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description. All features disclosed in this specification, or steps in all methods or processes implicitly disclosed, can be combined in any way, except for mutually exclusive features and / or steps.

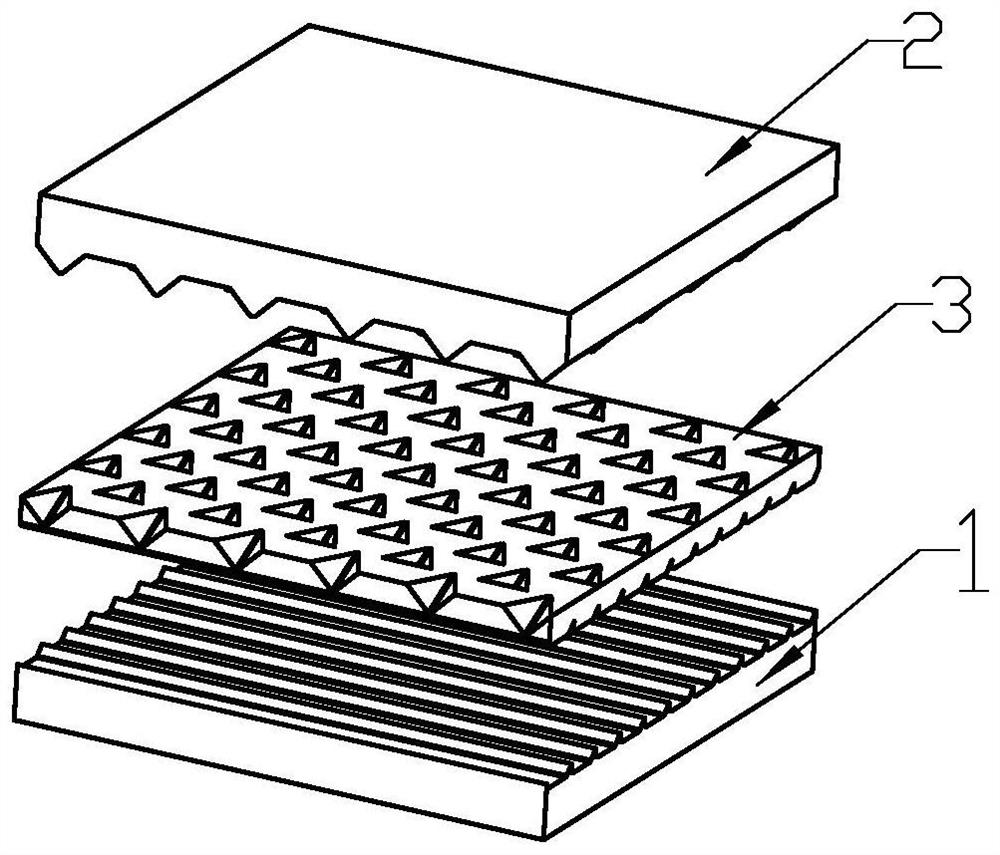

[0032] Such as figure 1 Shown, a kind of metal plate makes the method for micropore, comprises steps:

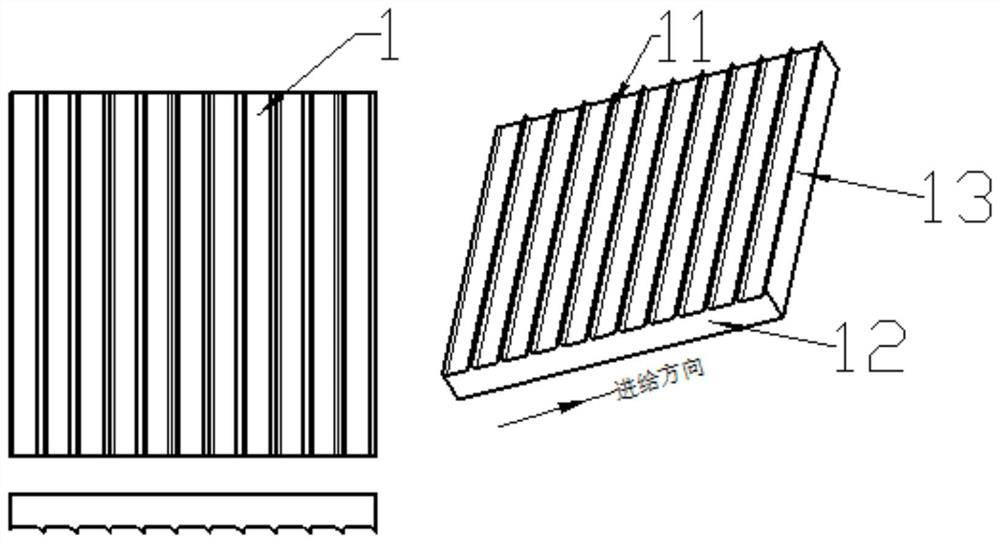

[0033] S1, making the sheet metal 3 be fed along the feeding direction 12 in the lower die 1 and aligned with the edge 13 of the lower die 1;

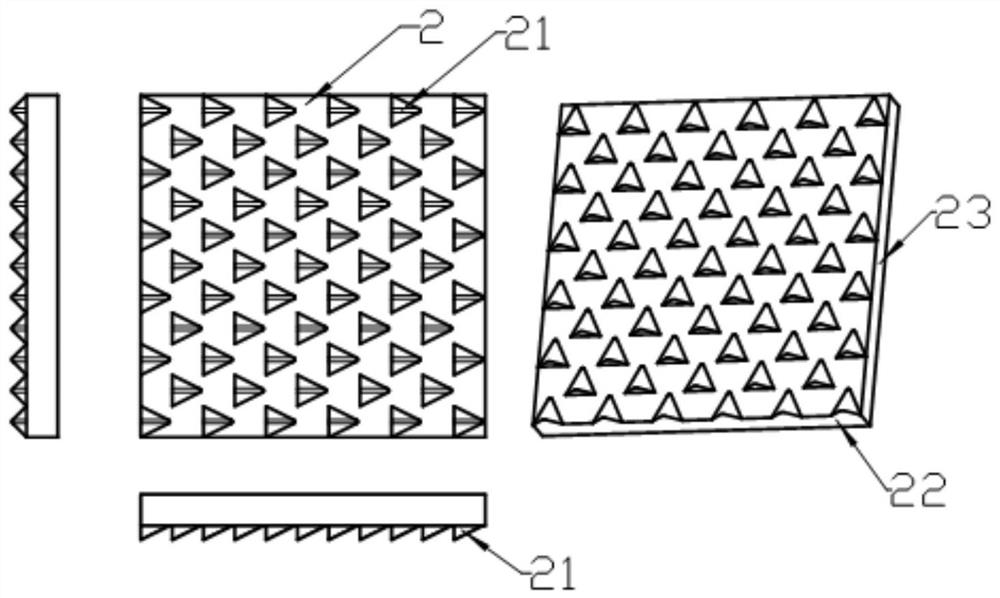

[0034] S2, the upper mold 2 is aligned with the edge of the lower mold 1, the upper mold 2 has unit blades distributed in a uniform lattice; the lower mold 1 has a plurality of strip-shaped blades 11 perpendicular to the feeding direction 12;

[0035] S3, the upper mold 2 applies a vertical punching force toward ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| ductility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com