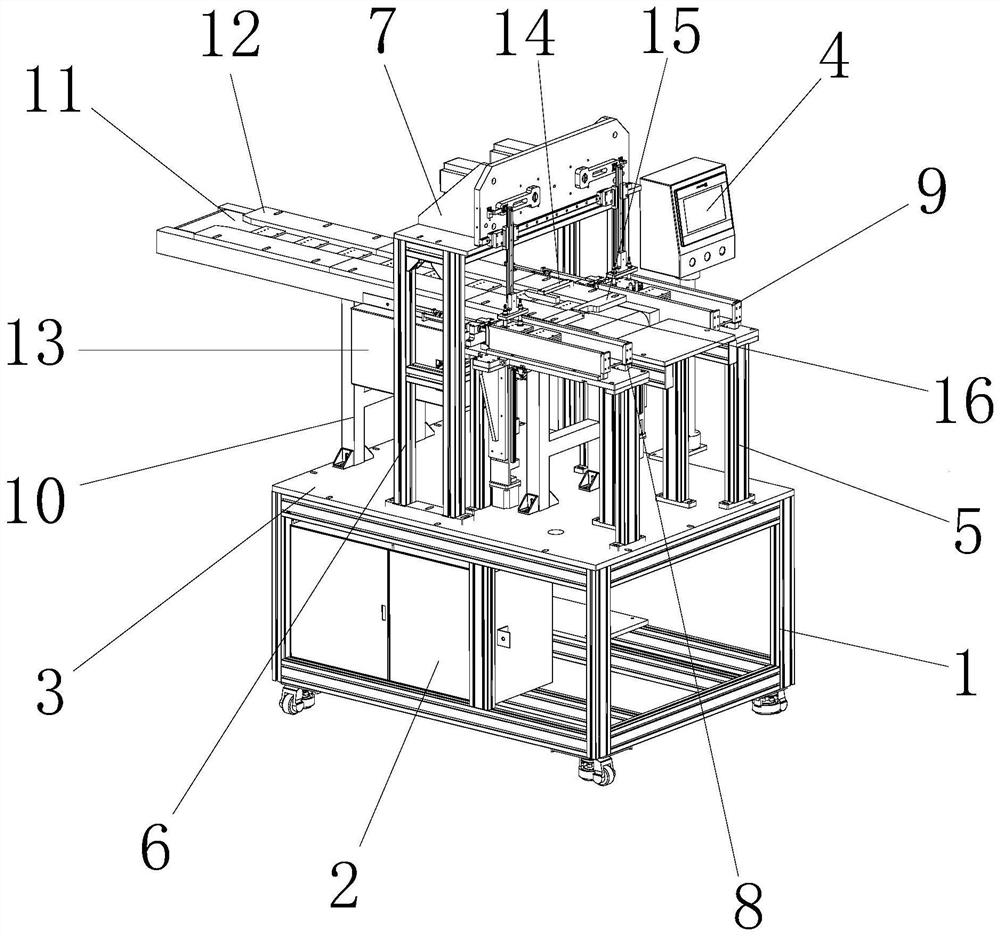

Automatic arraying machine for aluminum profiles

An aluminum profile and aligning machine technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of high labor intensity and high manual operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026]1. The stamped aluminum profile products slide down to the conveyor belt 11 one by one, and the conveying power motor 13 transfers the aluminum profile products backward, and automatically adjusts the product direction through the guide plate 12 and the guide 14, and then moves to the limit one by one The stall 15 is to be transferred, and the quantity of incoming materials is detected by the feed sensor 16, and the feed start and stop are controlled;

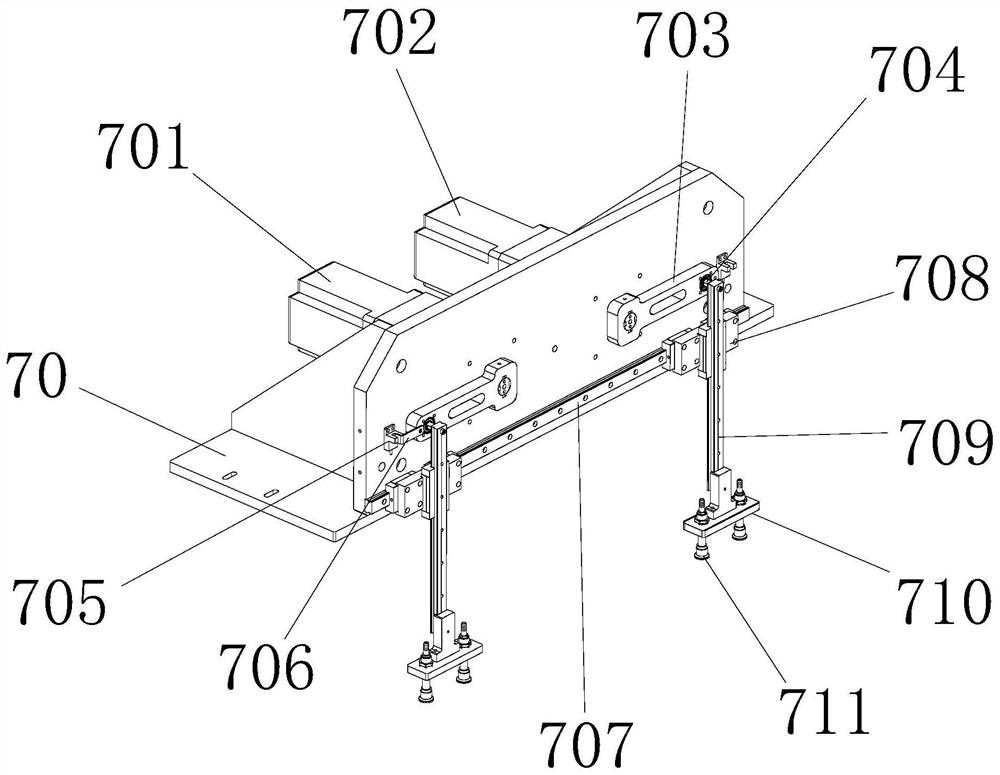

[0027]2. The left material moving motor 701 on the left and right transfer mechanism 7 rotates clockwise to take the material, and the vacuum suction cup 711 on the left is driven by the material moving swing arm 703 to pick up the aluminum profile product, and then the left material moving motor 701 rotates counterclockwise 180 When the angle sensor 706 rotates to the position of the angle sensor 705, the angle sensor 705 sends a signal to the control system to loosen the aluminum product on the vacuum suction cup 711 and place i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com