Stamping device for automobile chassis part production

A stamping device and automobile chassis technology, which is applied in the stamping field of auto parts, can solve problems such as easy splashing and staff injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

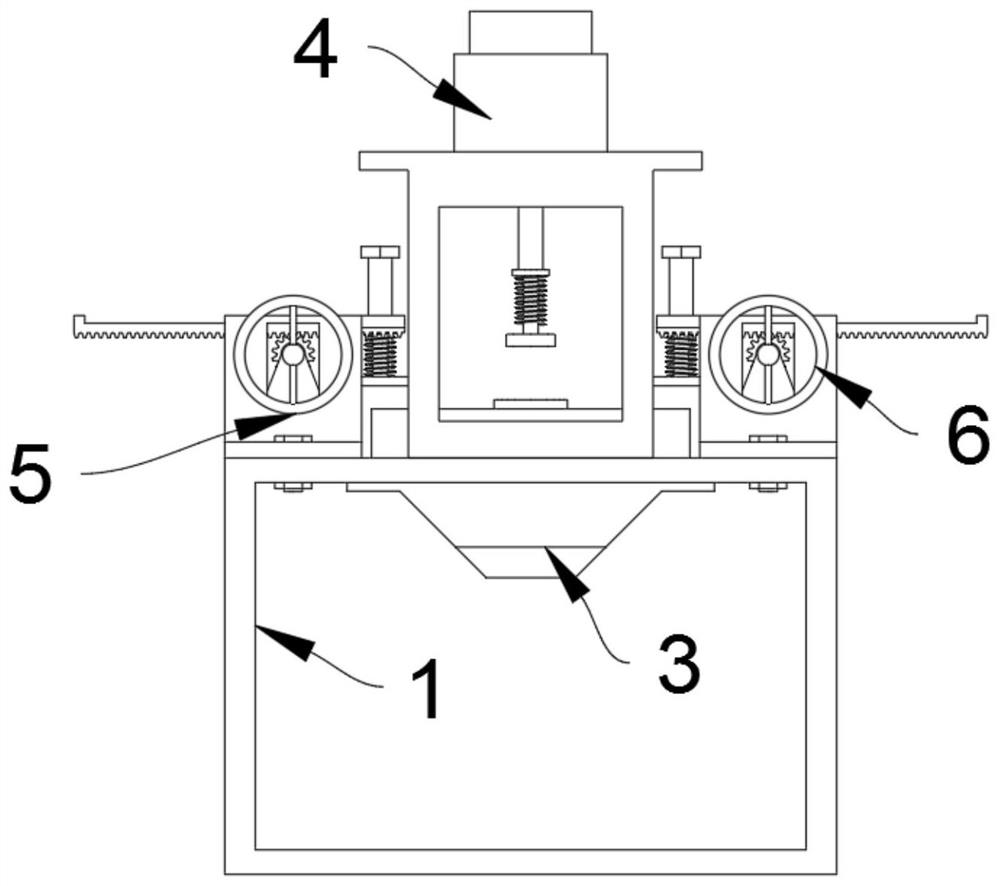

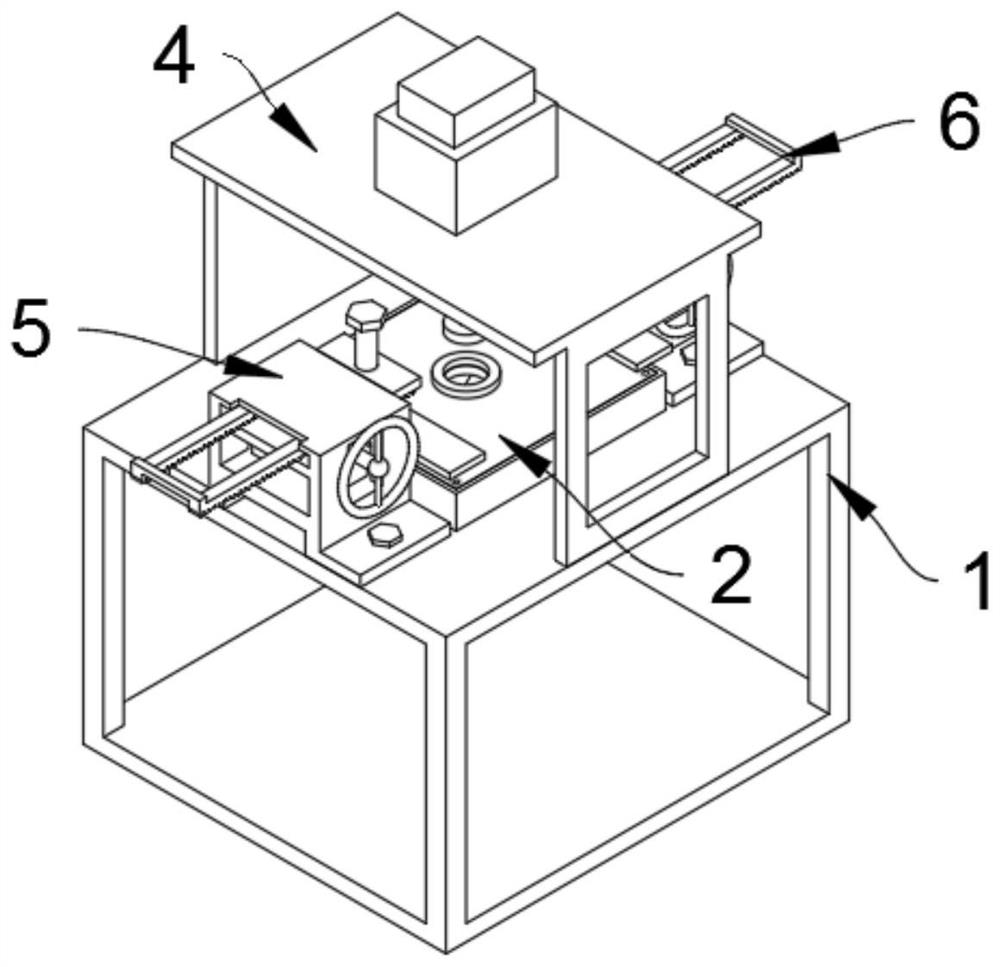

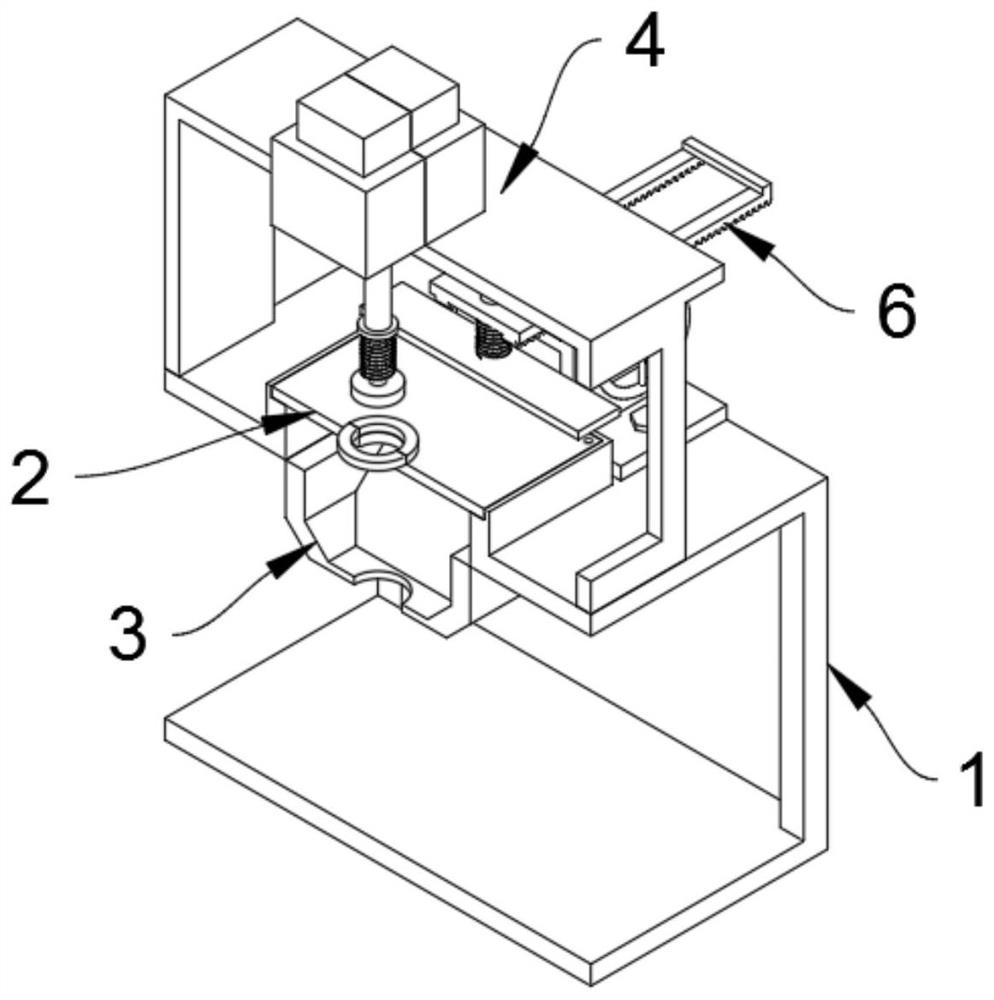

[0034] as attached figure 1 to attach Figure 11 Shown:

[0035]The present invention provides a stamping device for the production of automobile chassis parts, comprising: a support mechanism 1, a first limit mechanism 5, and a second limit mechanism 6, and the middle position of the top of the support mechanism 1 is fixedly connected with a platen mechanism 2; The middle position inside the mechanism 1 is fixedly connected with the top of the storage mechanism 3; the storage mechanism 3 includes a collection box 301, a collection tank 302, and a discharge hole 303. The discharge hole 303, the discharge hole 303 is connected with the collection tank 302; the middle position of the top of the bracket mechanism 1 is fixedly connected with the bottom of the stamping mechanism 4; The bottom of the position mechanism 6 is fixedly connected to the middle right side of the top of the bracket mechanism 1.

[0036] Wherein, the support mechanism 1 includes a support frame 101 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com