Ultra-thick slab continuous casting tundish butt-joint speed increasing operation method

A slab continuous casting and operation method technology, applied in the field of iron and steel production, can solve problems such as difficult production operations, achieve good promotion value, improve stability, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

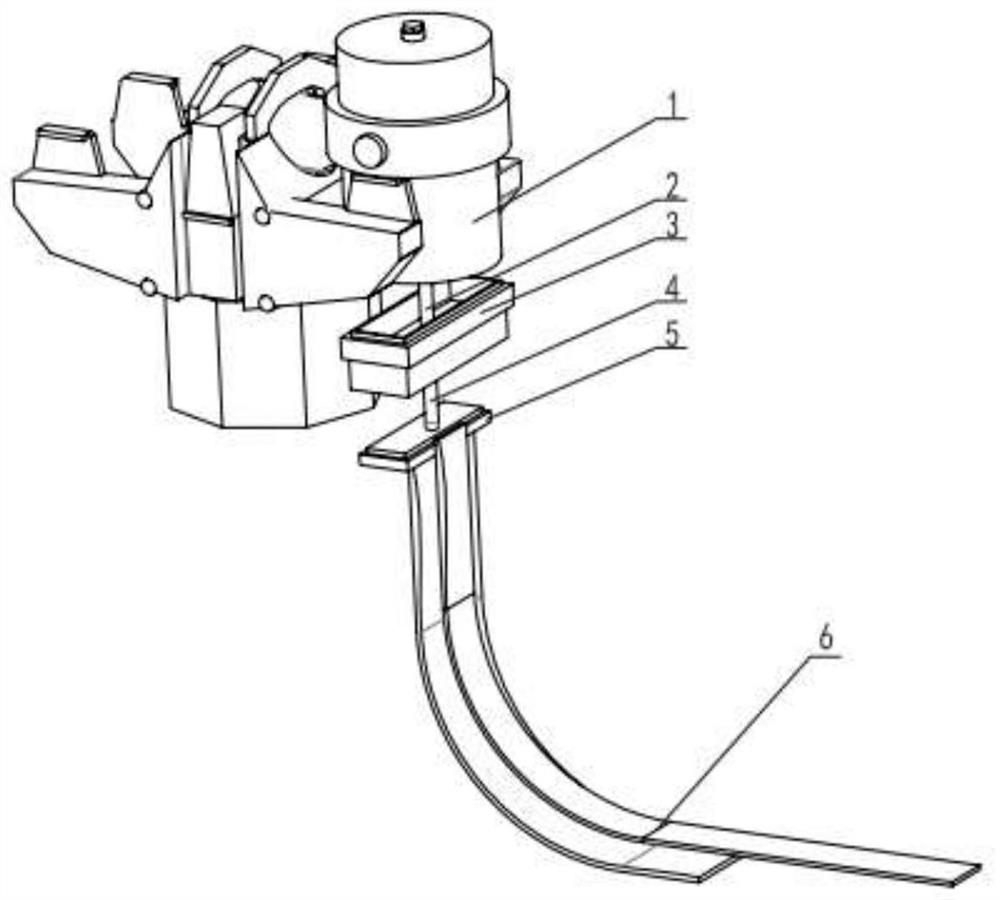

[0044] This embodiment provides a super-thick slab continuous casting tundish butt joint speed-up operation method, such as figure 1 shown, including the following steps:

[0045] (1) Tundish docking

[0046] S1. After the pouring of the last furnace of the last group is completed, rotate the turret of ladle 1 to the horizontal position, and prepare to measure the remaining molten steel depth in the tundish. slag;

[0047] S2. When the remaining molten steel in the tundish is below 30t, reduce the production speed and start measuring the depth of molten steel in the tundish;

[0048] S3. When the tonnage of the tundish reaches 20t, check the spare baking tundish;

[0049] S4. When the tonnage of the tundish reaches 15t, the casting speed is reduced to 0.8m / min; when the liquid level of the tundish is below 300mm, remove the pressure rod of the tundish stopper rod, close the rod, and at the same time drive into the blind plate, and the pouring position is produced The casti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com