Whole-row screw tightening device for recycling and disassembling power batteries

A power battery and screw technology is applied in the field of the whole row screw screwing device for power battery recycling and dismantling, which can solve the problems of slow disassembly speed, low power battery recycling efficiency, hidden safety hazards, etc., so as to reduce labor intensity and facilitate screws. The effect of the dismantling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

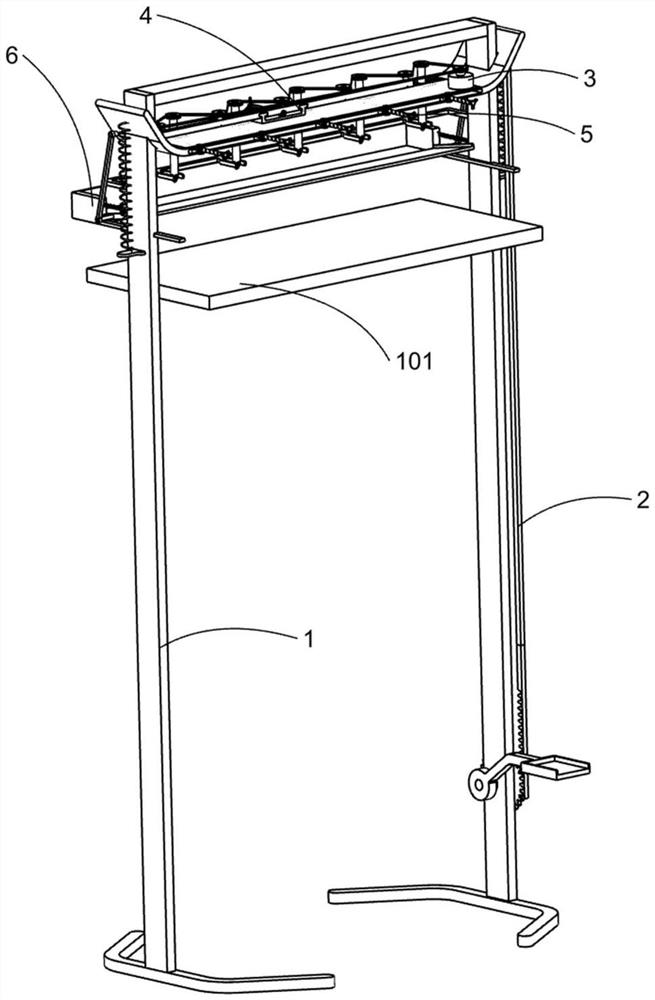

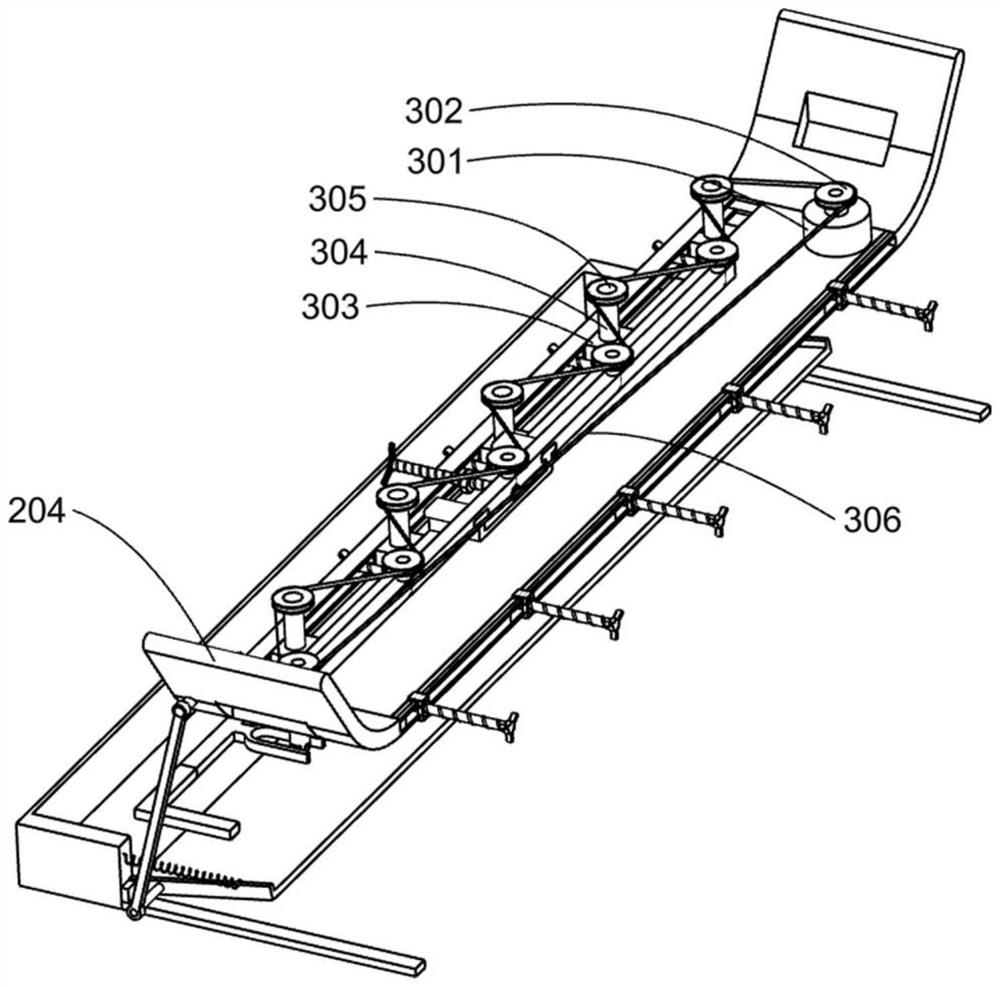

[0023] A whole row of screw screwing device for recovery and disassembly of power battery, such as Figure 1-7 As shown, it includes a bracket 1, a placement plate 101, a pedal lifting mechanism 2, a screw mechanism 3, a tightness adjustment mechanism 4, a fixing mechanism 5 and a screw collection mechanism 6, and the placement plate 101 for placing the power battery is fixed. On the inner side of the bracket 1, the pedal lifting mechanism 2 is arranged on the bracket 1, and the screw mechanism 3 for disassembling the screws on the power battery is arranged on the pedal lifting mechanism 2. The tightness adjusting mechanism 4 is arranged on the pedal lifting mechanism 2 and is connected with the screwing mechanism 3 , and the fixing mechanism 5 is arranged on the pedal lifting mechanism 2 and the screwing mechanism 3 .

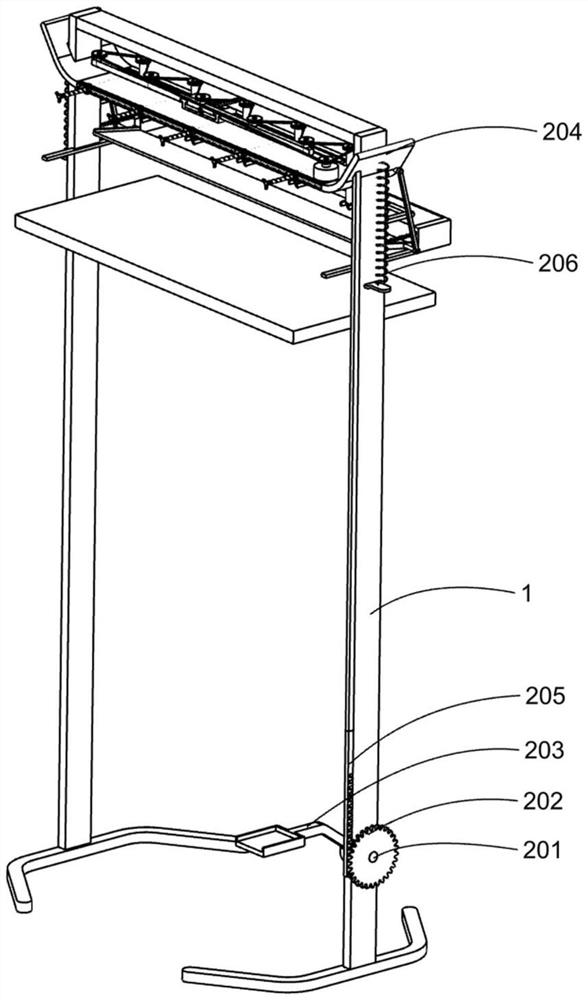

[0024] Specifically, the pedal lifting mechanism 2 includes a rotating shaft 201, a gear 202, a pedal 203, a lifting plate 204, a rack 205 and a return spring...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 and Figure 6-7 As shown, it also includes a screw collection mechanism 6 for collecting the disassembled screws. The screw collection mechanism 6 is arranged on the bracket 1 and the pedal lifting mechanism 2. The screw collection mechanism 6 includes a slide bar 601, Collecting frame 602, return spring 603, connecting rod and toggle lever 605, two slide grooves are provided on the support 1 and the slide rod 601 is slidingly arranged in the slide groove, and the two slide rods 601 are positioned above the placement plate 101 The collection frame 602 used to collect the screws dismantled from the screw rod 304 is fixed on one end of the two sliding rods 601, and two symmetrical return springs 603 are arranged between the collection frame 602 and the bracket 1, The collection frame 602 and the lifting plate 204 are rotatably provided with two symmetrical connecting rods, the lifting plate 204 can drive the collecting frame 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com