Press fitting device for control board production

A technology of a pressing device and a control board is applied in the field of parts assembly machinery, which can solve the problems of low feeding efficiency and feeding accuracy of shrapnel, and achieve the advantages of improving assembly efficiency and assembly stability, improving feeding accuracy and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

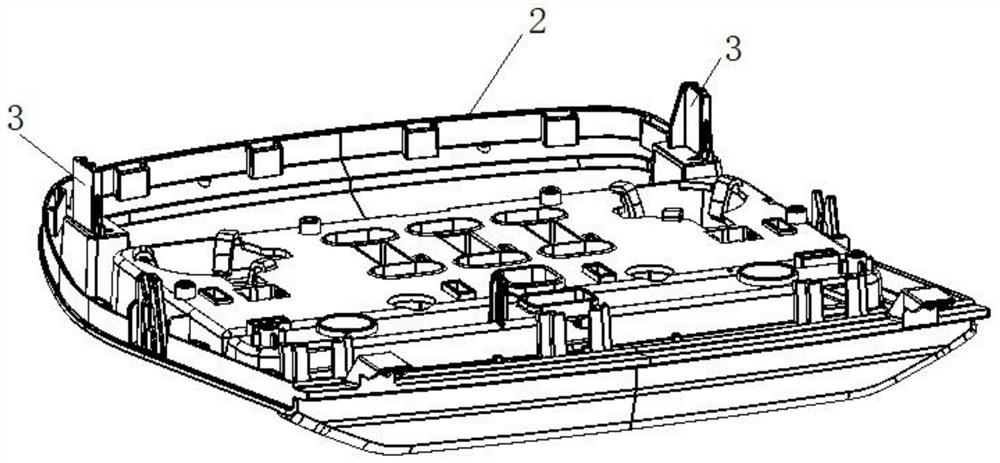

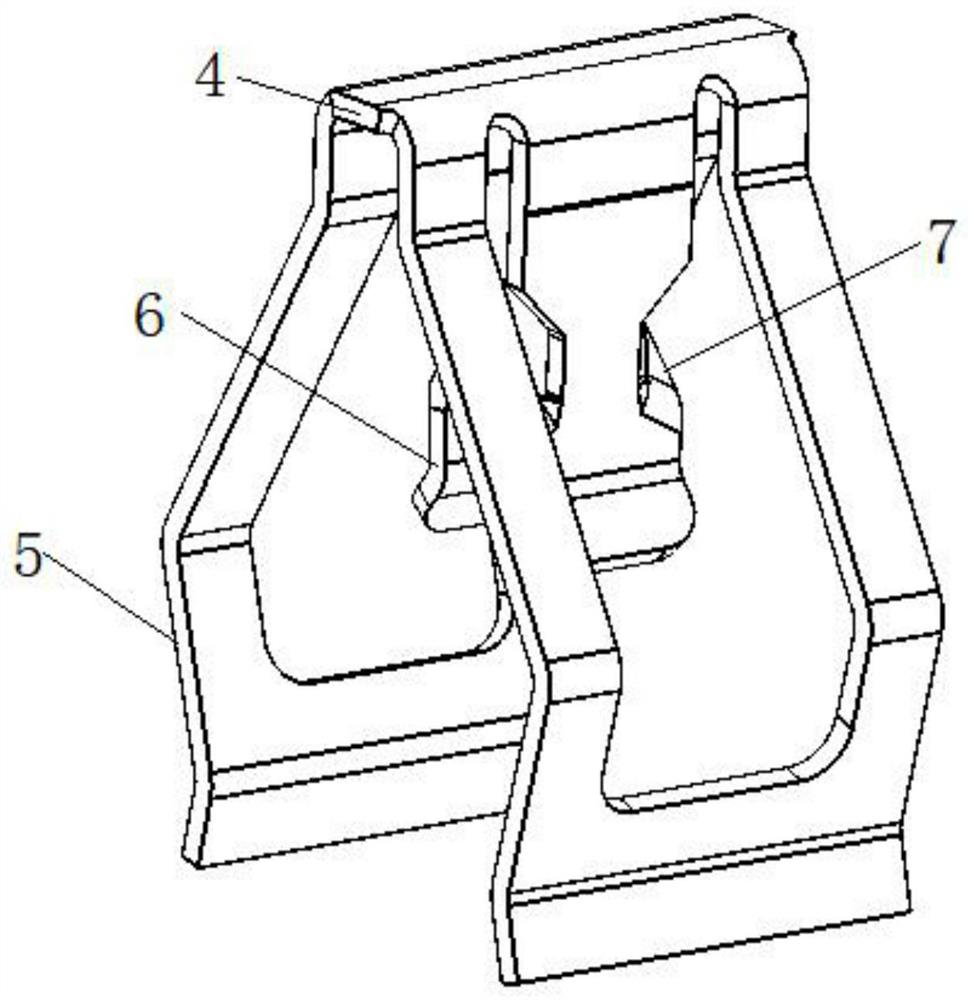

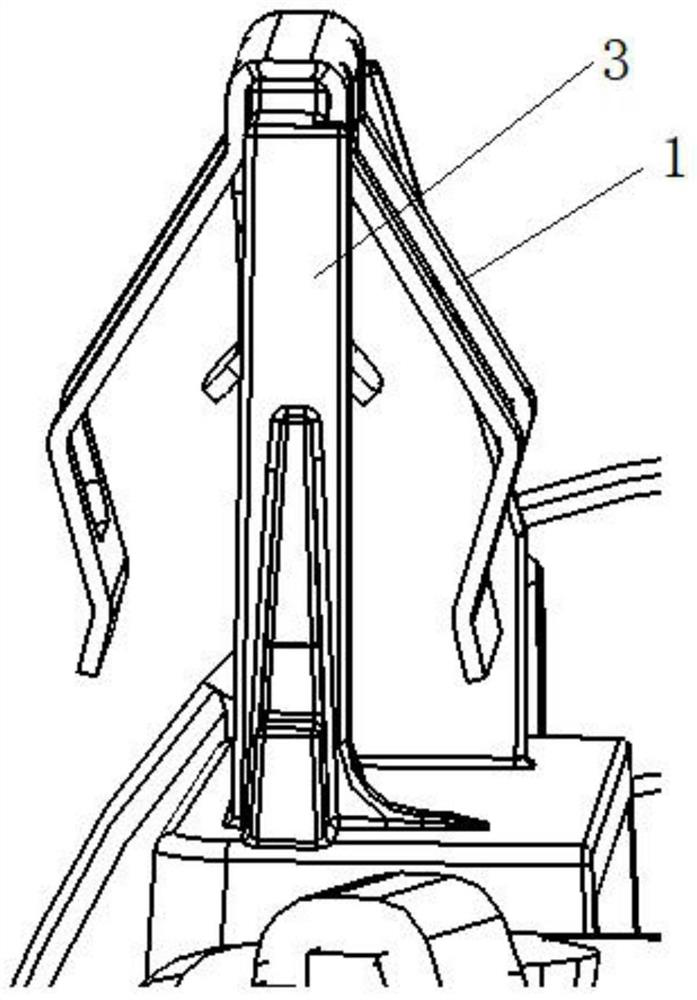

[0031] Such as Figure 1 to Figure 3 As shown, a pressing device used in the production of control boards is used to press the shrapnel 1 into the upwardly protruding blocks 3 on the left and right sides of the control board 2 . The shrapnel 1 is formed by bending and stamping a metal sheet. The top of the shrapnel 1 is provided with lugs 4 . Inside the lugs 4 is a non-circular groove structure. The bottom of the lugs 4 is connected to a pair of main clips with the opening facing downward. Arm 5, and a pair of auxiliary clamp arms 6 with openings facing downwards, the bottom of the auxiliary clamp arms 6 is higher than the bottom of the main clamp arms 5, and the opening width of the pair of secondary clamp arms 6 is smaller than the opening width of the pair of main clamp arms 5 ; The auxiliary clamp arm 6 is provided with oppositely bent pincer angles 7 , and after the shrapnel is pressed into the block 3 , the pair of pincer angles 7 clamps the block 3 .

[0032] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com