An automatic filling mechanism for emulsion cosmetics with guaranteed accuracy

A high-precision technology for cosmetics, applied in the field of automatic filling mechanism for emulsion cosmetics, can solve problems such as waste, overflow, and reduce the practicality of cosmetic tank liquid equipment, and achieve the effects of improving rationality, avoiding leakage, and improving filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

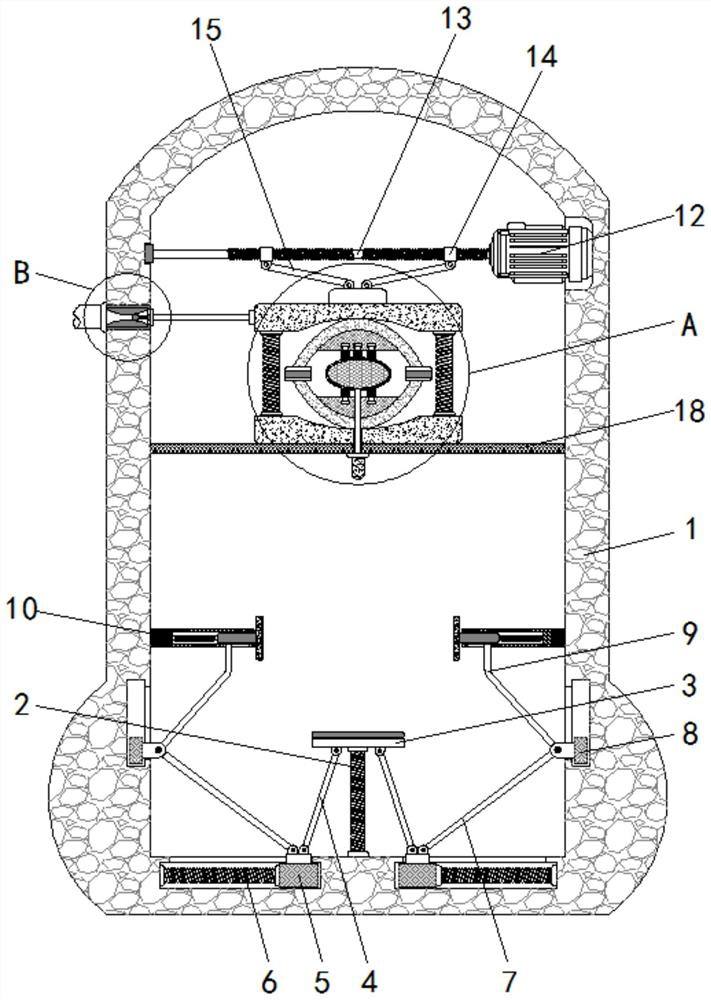

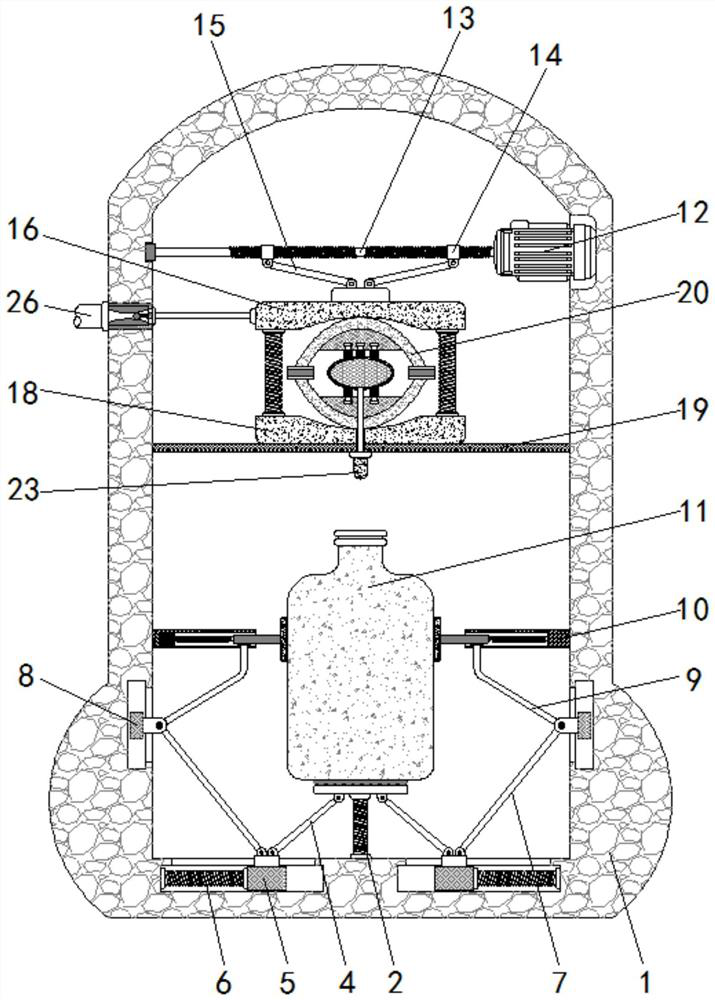

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] as attached figure 1 to attach Figure 6 Shown:

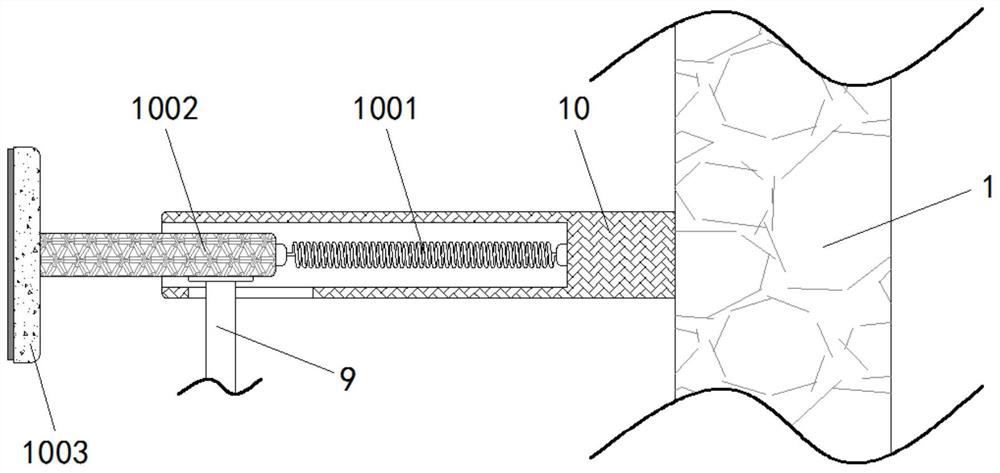

[0027] The invention provides an automatic filling mechanism for emulsion cosmetics with guaranteed accuracy, which includes a main body 1, a support spring 2 is fixedly installed on the bottom of the inner wall of the main body 1, a bearing plate 3 is fixedly installed on the upper side of the support spring 2, and the upper side of the bearing plate 3 A tank body 11 is provided, and the emulsion cosmetics are received by the tank body 11. The lower side of the bearing plate 3 is movably installed with a first movable connecting rod 4, and the lower end of the first movable connecting rod 4 is movably connected with a first slider 5. The main body 1 A chute is provided at the bottom of the inner wall, and a spring mechanism 6 is installed on the inner wall of the chute, and the other end of the spring mechanism 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com