Tracking-resistant addition type liquid silicone rubber composition and preparation method and application thereof

A liquid silicone rubber, tracking resistance technology, applied in the field of high-voltage and ultra-high electrical insulation of silicone rubber, can solve the problems of low fluorosilane content, reduced crosslinking density of silicone rubber, and reduced tracking resistance of silicone rubber, etc. Achieve good water resistance, good stability, and improve the effect of tracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

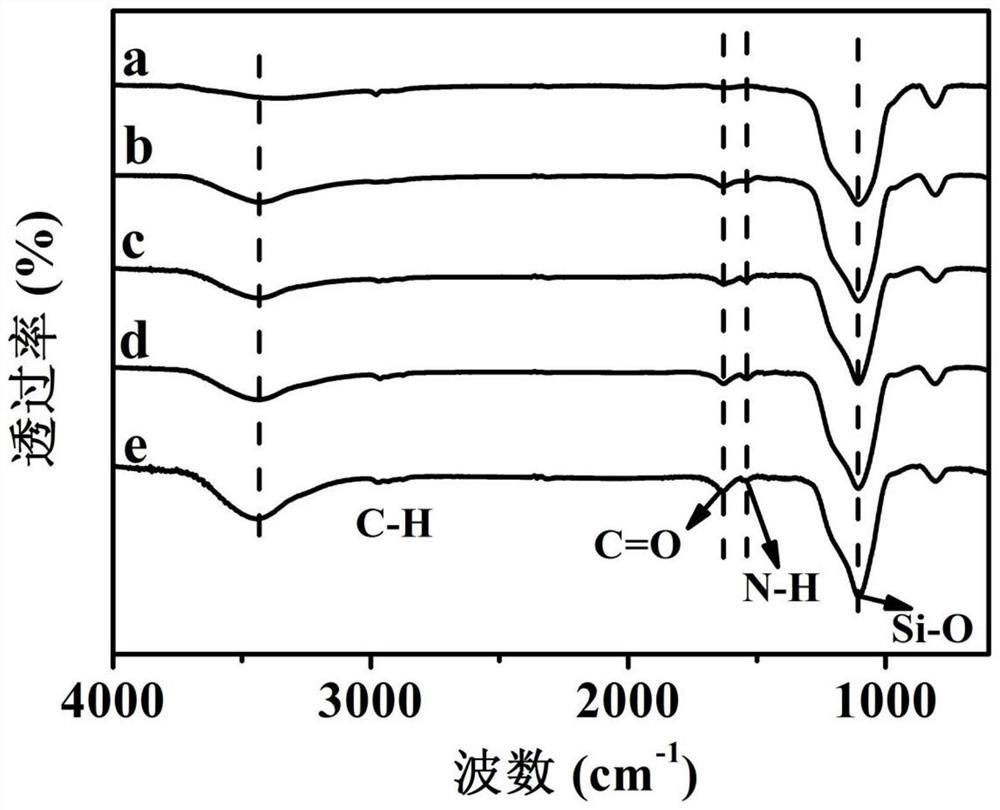

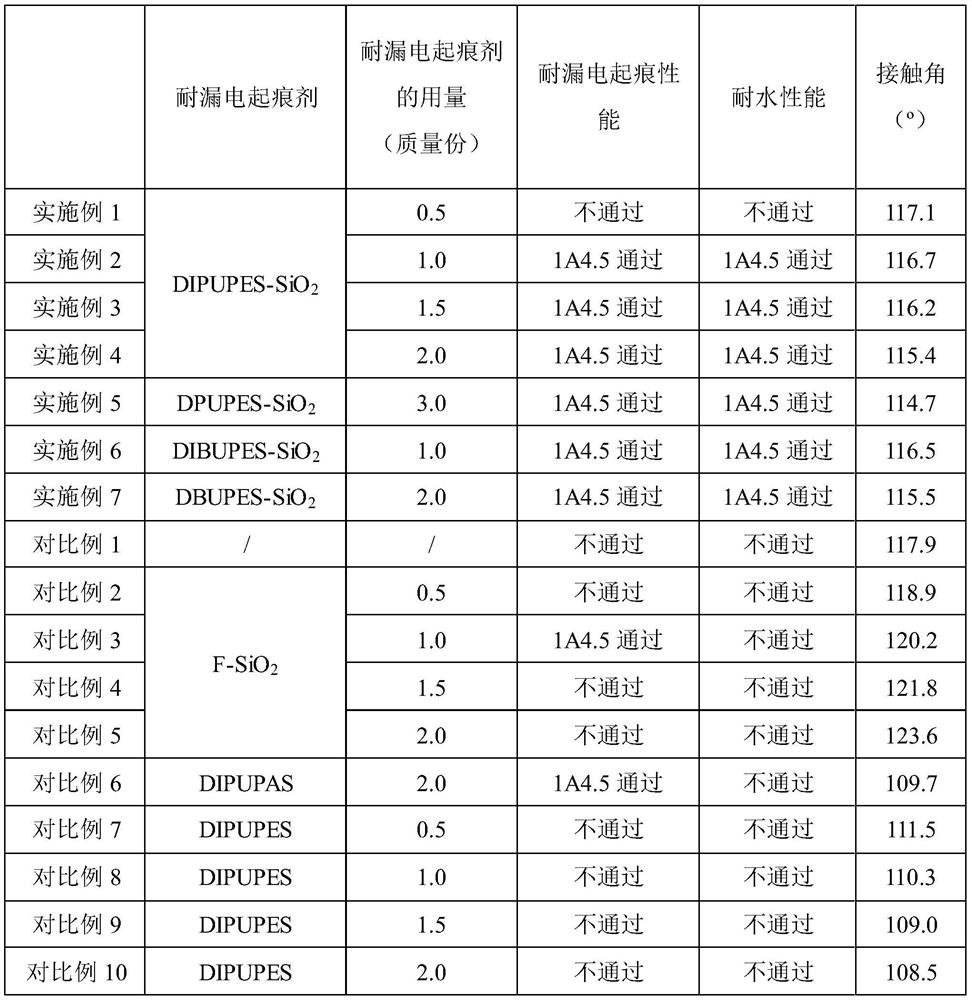

[0036] Add 10.00g of silicon dioxide to a three-necked flask filled with 296.00g of absolute ethanol, and ultrasonically stir for 2h to obtain a dispersion; .Effect of alkyl-dissubstituted ureido silanes with different alkyl chain structures ontracking resistance property of addition-cure liquid silicone rubber, Polym. Degrad. Stabil. 142 (2017) 263-272.) Preparation of isopropyl disubstituted ureido siloxane Add 41.00g of ammonia water to the dispersion, heat up to 70°C, react for 4 hours, centrifuge the obtained reaction solution, rinse the obtained solid with 30.00g of absolute ethanol, then perform centrifugation, and repeat the separation Operate 3 times, finally, solid matter is dried, obtains powdery product silicon dioxide grafted isopropyl group disubstituted ureido siloxane (DIPUPES-SiO 2 ).

[0037] In terms of parts by mass, mix 100 parts of vinyl silicone oil, 40 parts of white carbon black and 6.8 parts of hexamethyldisilazane in a vacuum kneader, knead at 30°C ...

Embodiment 2

[0039] The difference between embodiment 2 and embodiment 1 is that DIPUPES-SiO 2 The addition amount is 1.0 parts.

Embodiment 3

[0040] The difference between embodiment 3 and embodiment 1 is that DIPUPES-SiO 2 The addition amount of is 1.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com