A tail light bracket and its processing technology

A processing technology and technology for taillights, which are used in bicycle accessories, optical signals, transportation and packaging. Rust effect, perfect effect of anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0035] Linseed oil monoester is prepared by reacting linseed oil and glycerol at 240°C for 2 hours at a weight ratio of 2:1.

Embodiment 1

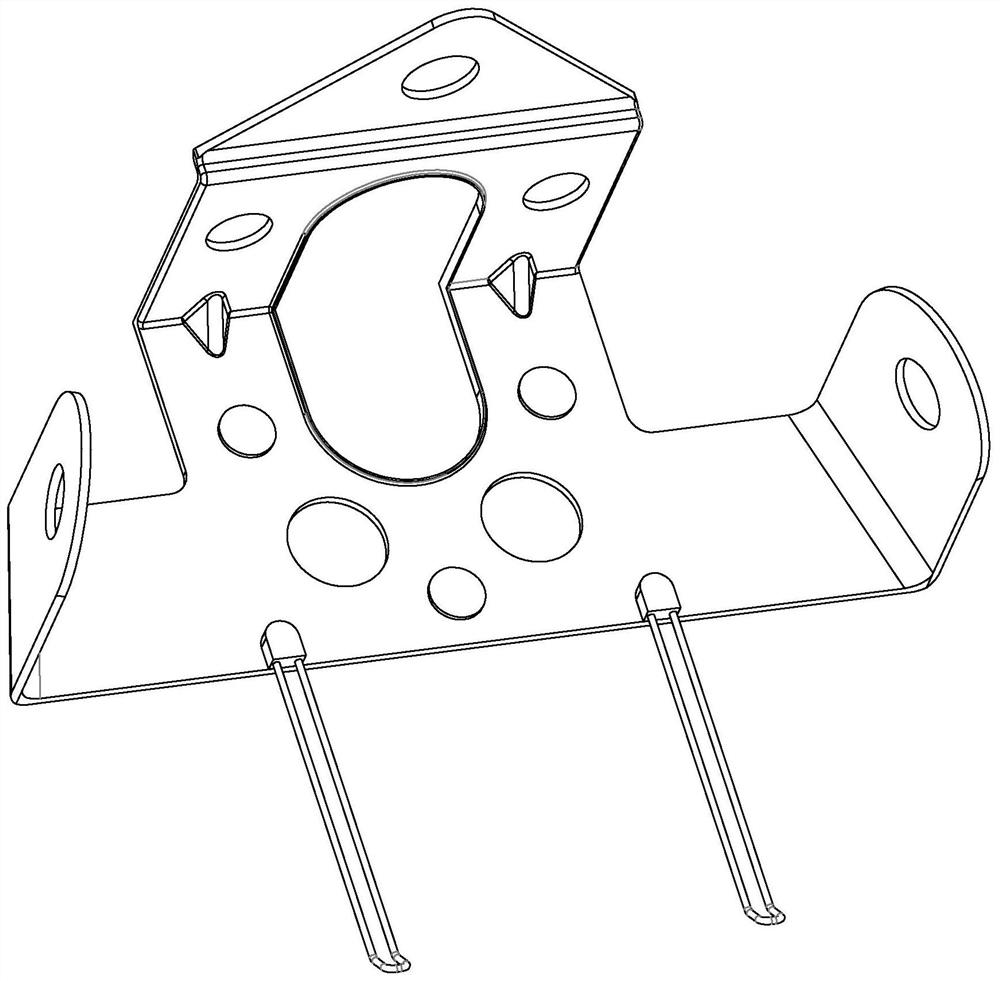

[0038] The application discloses a car tail light bracket and its processing technology, the car tail light bracket is as follows figure 1 As shown, the processing technology includes the following steps:

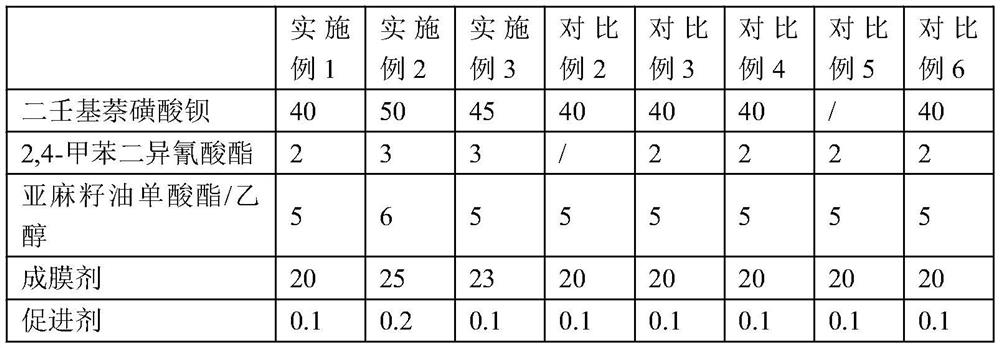

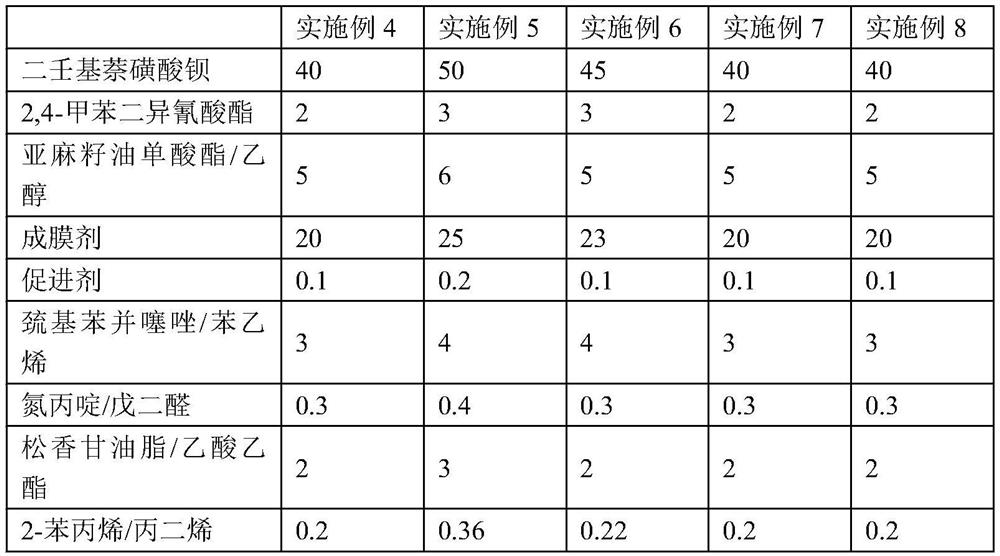

[0039] S1. Preparation of surface treatment agent; weigh the required components, first stir and mix linseed oil monoester and barium dinonyl naphthalene sulfonate for 5 minutes, then add 2,4-toluene diisocyanate and accelerator triethylene diisocyanate Amine, heat up to 45°C, stir and mix for 15 minutes; keep warm and add acrylic resin film-forming agent, continue stirring for 20 minutes to obtain a surface treatment agent;

[0040] S2. Surface treatment agent treatment; the surface of the taillight bracket is polished and degreased, and the surface treatment agent of S1 is sprayed on the taillight bracket, and placed in a dry and ventilated place to dry for 12 hours;

[0041] S3. Brush epoxy asphalt topcoat; paint a layer of epoxy asphalt topcoat on the surface of the ta...

Embodiment 2

[0044] The application discloses a car tail light bracket and its processing technology, the car tail light bracket is as follows figure 1 As shown, the processing technology includes the following steps:

[0045] S1. Preparation of surface treatment agent; Weigh the required components, first stir and mix linseed oil monoester and barium dinonyl naphthalene sulfonate for 8 minutes, then add 2,4-toluene diisocyanate and accelerator triethylene diisocyanate Amine, heat up to 50°C, stir and mix for 20 minutes; keep warm and add butadiene resin film-forming agent, continue stirring for 30 minutes to obtain a surface treatment agent;

[0046] S2. Surface treatment agent treatment; the surface of the taillight bracket is polished and degreased, and the surface treatment agent of S1 is sprayed on the taillight bracket, and placed in a dry and ventilated place to dry for 24 hours;

[0047] S3. Brush epoxy asphalt topcoat; paint a layer of epoxy asphalt topcoat on the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com