Conductive foam double-sided adhesive tape

A technology of double-sided tape and conductive foam, which is applied to adhesives, film/sheet adhesives, etc., can solve problems affecting adhesiveness, peeling, graphite layer cracking, etc., and achieve low manufacturing process and cost. The effect of simple structure and few structural layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

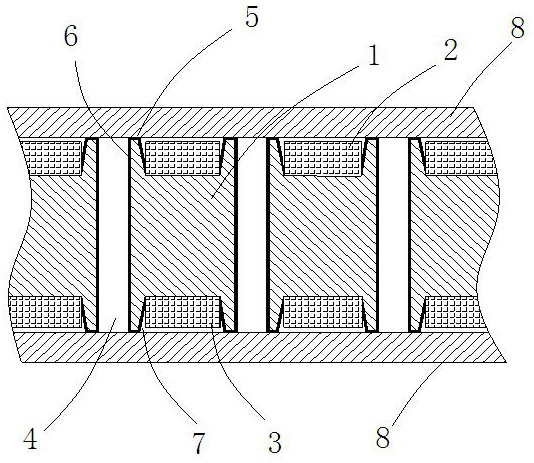

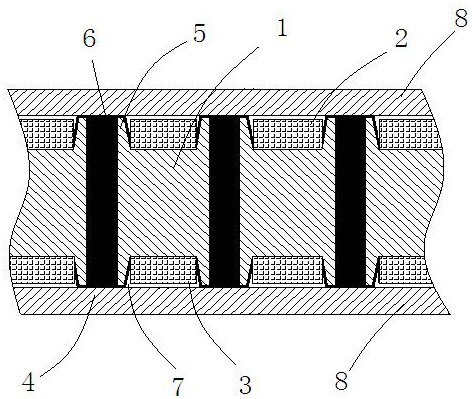

[0033] Such as figure 1 As shown, a conductive foam double-sided adhesive tape includes: a foam substrate 1, the upper and lower surfaces of the foam substrate are respectively provided with a first adhesive layer 2 and a second adhesive layer 3;

[0034] The surface of the foamed base material is evenly provided with a plurality of first through holes 4, and the upper and lower surfaces of the foamed base material at both ends of each first through hole are respectively provided with a boss 5, and the first through hole communicates with the boss;

[0035] The surface of the boss is connected to the first through hole with a conductive material layer 6; the conductive material layer enables the conductive foam double-sided tape to realize conductive connection on both sides;

[0036] A second through hole 7 adapted to the shape and position of the boss is formed on the first adhesive layer and the second adhesive layer, and the boss is arranged in the second through hole, and...

Embodiment 2

[0047] Similar to Embodiment 1, the difference lies in that the foam base material, the boss and the first through hole are integrally formed.

Embodiment 3

[0049] Similar to Embodiment 1, the difference lies in that the first through hole is arranged obliquely. The inclined first through hole has better adaptability to the compression deformation of the foamed substrate, and can better prevent the conductive material layer from peeling off during die cutting or long-term use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com