Light steel keel structure and construction method thereof

A light steel keel and main keel technology, which is applied in building components, building structures, buildings, etc., can solve the problems of poor corrosion resistance, easy deformation, cracking, etc., and achieve the effect of strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

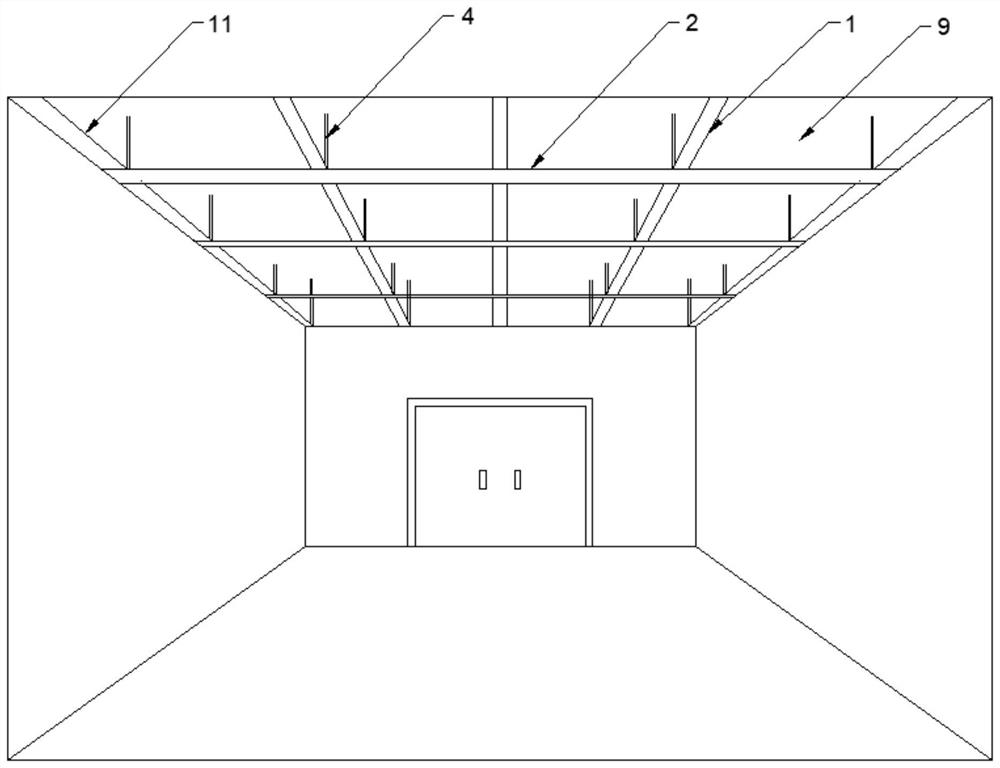

[0028] Such as figure 1 As shown, a light steel keel structure provided in this embodiment is installed below the top of the wall 9 .

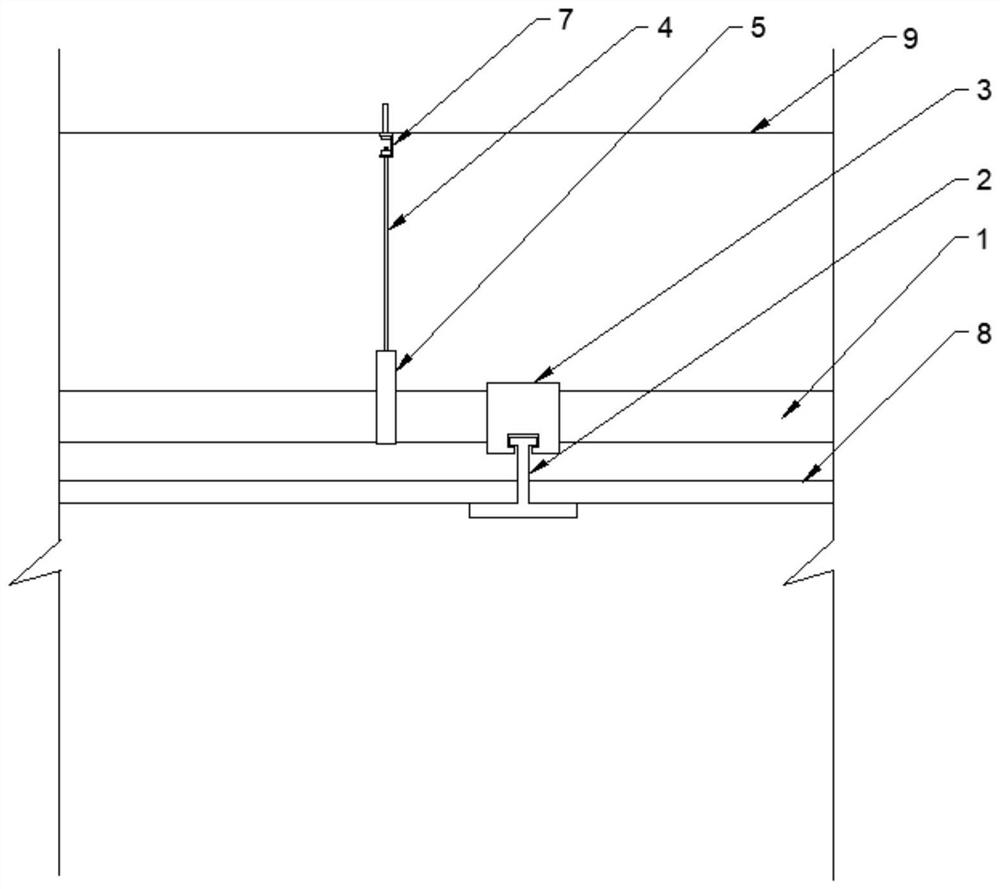

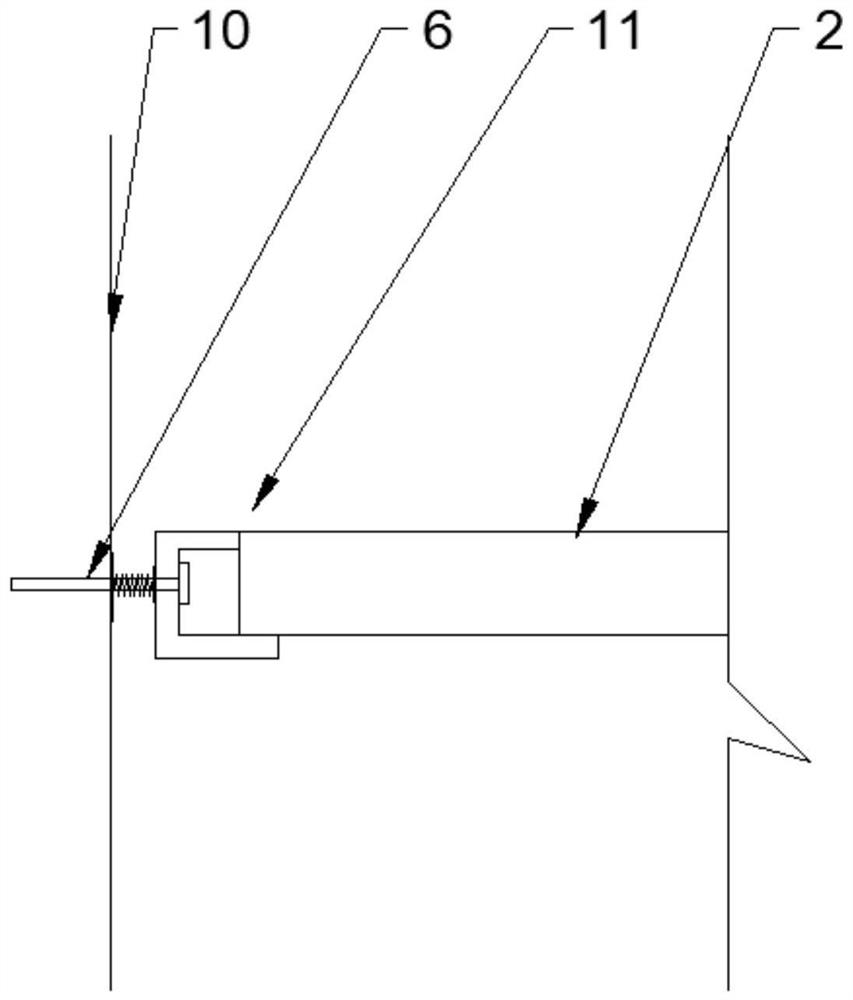

[0029] A light steel keel structure provided in this embodiment, such as figure 2 As shown, it includes the main keel 1, the secondary keel 2, the pendant 3, the side keel 11 and the suspender 4. It is characterized in that the top of the suspender 4 is fixedly connected with a hanger 7, and the hanger 7 is perpendicular to the top of the wall 9 and fixed. Connection; the main keel 1 is fixedly connected to the bottom of the boom 4 through the support 5; the secondary keel 2 is fixedly connected to the lower surface of the main keel 1 through the pendant 3 arranged on the main keel, and the secondary keel 2 is parallel to the ground and connected to the main keel 1 is vertical; the side keel 11 is fixed on the upper half of the wall 10 through flexible connectors;

[0030] In the light steel keel structure provided in this embodiment, a cer...

Embodiment 2

[0038] This embodiment provides a light steel keel structure construction method for installing the light steel keel structure in Example 1, such as Figure 5 As shown, the construction method includes:

[0039] S101: Mark the position of the main keel 1 and the fixing point of the suspender 4 on the top of the wall 9, and mark the installation level line of the side keel 11 on the wall 10.

[0040] Among them, the size of the main keel 1 is 38×0.8 unit mm, parallel to the long side of the room, and the size of the secondary keel 2 is 50×0.8 unit mm, parallel to the ground and perpendicular to the main keel 1. The spacing between multiple parallel main keels 1 is set to 800mm; the length of the boom is set to 800mm; the spacing between multiple parallel secondary keels 2 is 400mm.

[0041] S102: Install expansion bolts at the fixing point of the suspension rod 4 on the top of the wall, and fix the suspension rod 4 under the expansion bolts through the hanging piece 7 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com