Formwork system for top longitudinal beam and mid-span buckling arch of PBA underground excavation station and construction method

A formwork system and top longitudinal beam technology, applied in earthwork drilling, shaft lining, tunnel lining, etc., can solve problems such as long installation time, large labor demand, dangerous installation and dismantling, etc., reduce operating personnel and solve labor problems Intensity, the effect of reducing the probability of accidents with mass casualties and casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

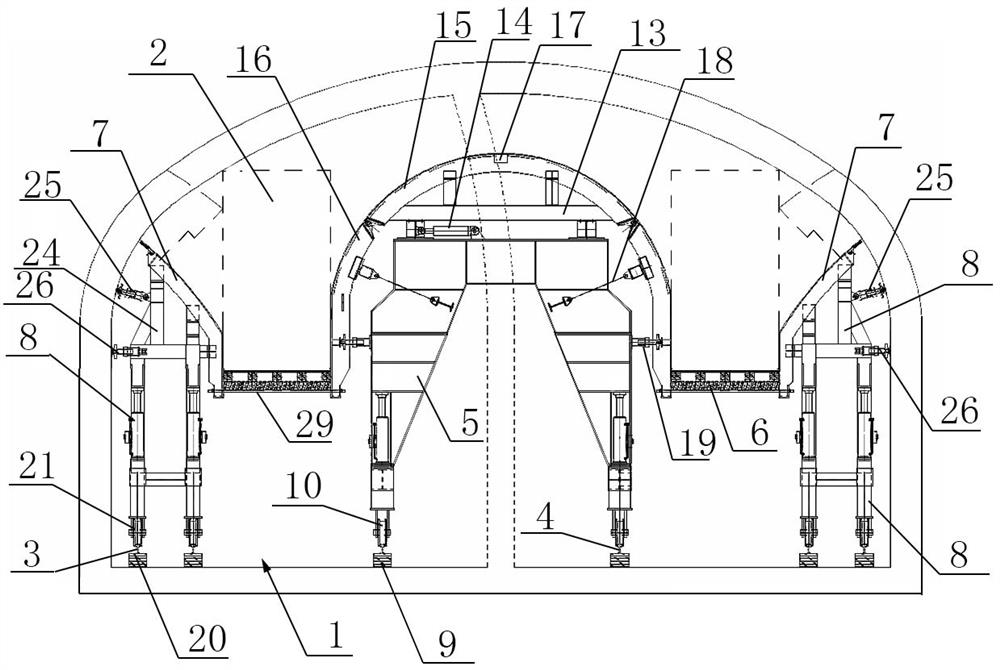

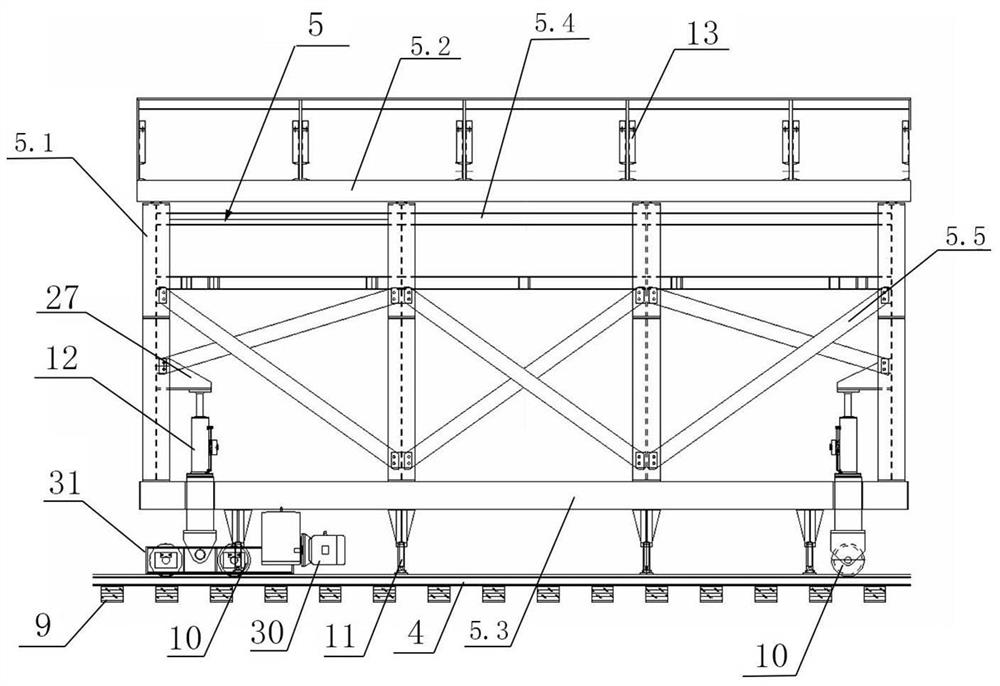

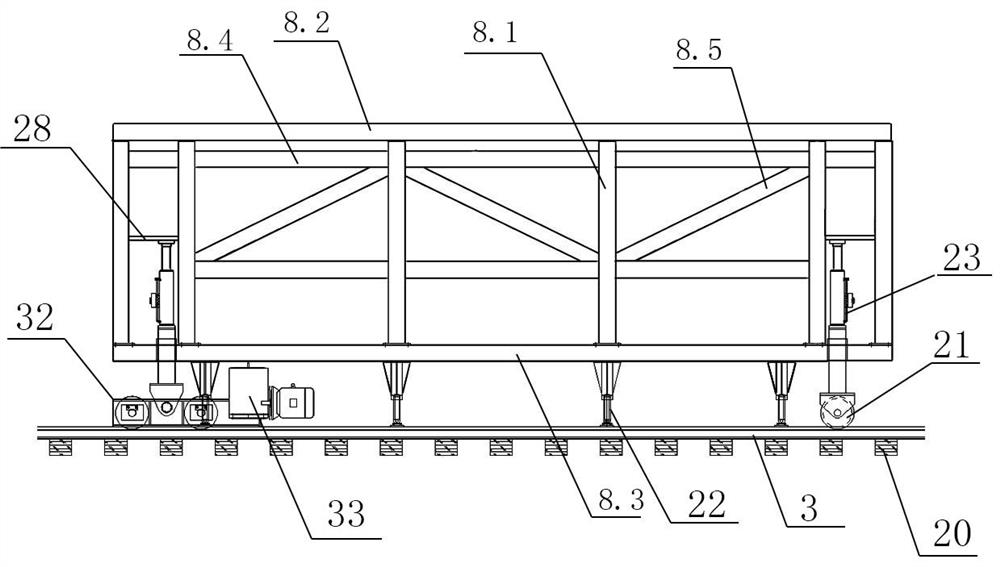

[0044] like Figure 1-4 As shown, the formwork system of the roof longitudinal beam and mid-span buckle arch of this PBA underground excavation station is installed in the excavated pilot tunnel 1; in the pilot tunnel 1, longitudinal support beams are respectively arranged on both sides of the bottom of the vault 2;

[0045] The formwork system includes side guide rails 3, middle guide rails 4, trolley 5, buckle arch formwork structure, beam bottom formwork structure 6, beam side formwork structure 7 and side support frame 8; the middle guide rail 4 is installed in the guide hole 1 at a position between two longitudinal support beams 2 to be poured; the side guide rails 3 are installed on both sides of the bottom of the guide hole 1 and are respectively located at outer positions of the longitudinal support beams 2 to be poured;

[0046] The trolley 5 is installed on the intermediate rail 4, and the bottom of the intermediate rail 4 is provided with a first sleeper 9; the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com