Novel continuous sine tooth profile and gear pair thereof

A gear pair, sinusoidal technology, applied in belt/chain/gear, components with teeth, portable lifting devices, etc., can solve the problem of not solving the impact of gear teeth meshing and meshing, difficult to ensure meshing accuracy, manufacturing and installation. High precision requirements, to achieve the effect of reducing tooth surface contact stress, improving bearing capacity, and high bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

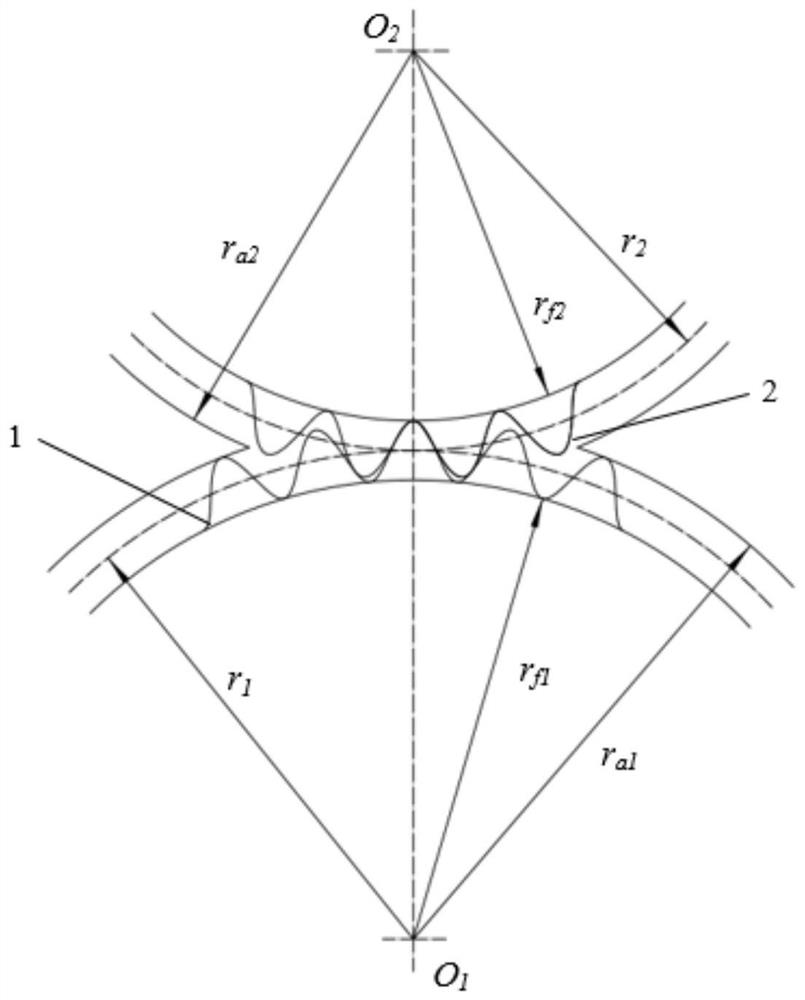

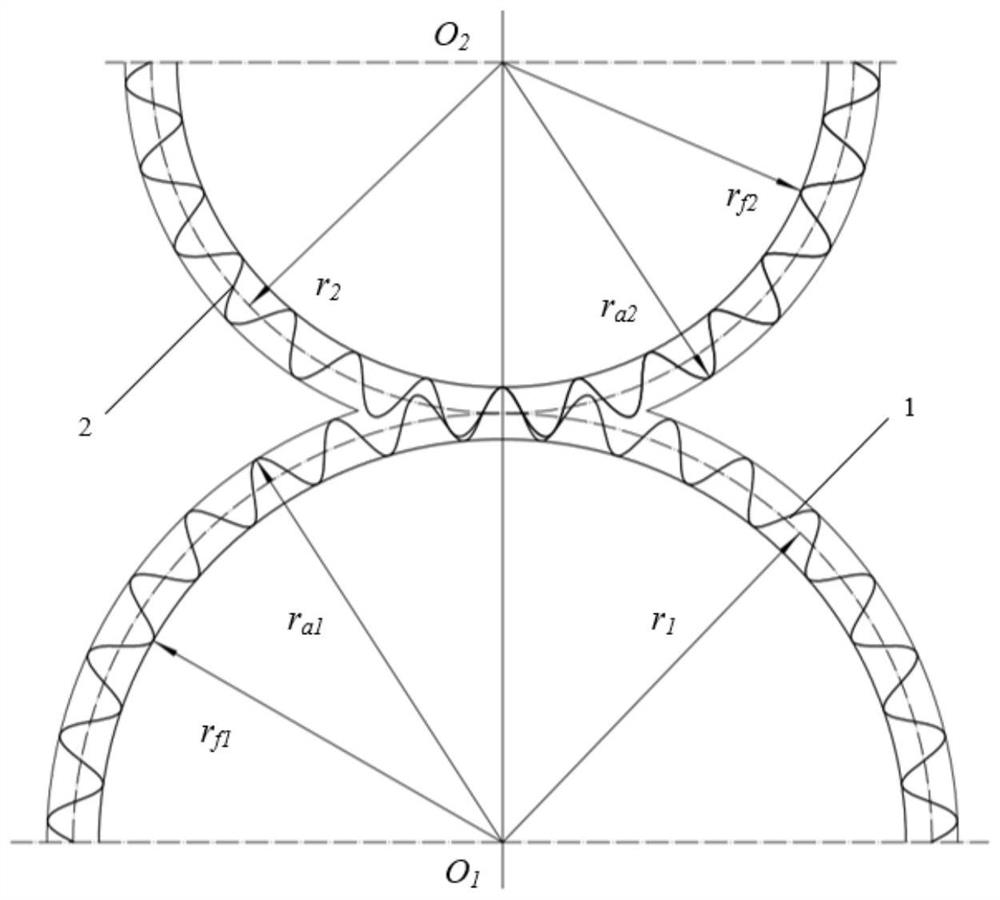

[0056] like Figure 1-3 As shown, the present invention provides a novel continuous sinusoidal tooth profile, including: a reference sinusoidal tooth profile and a conjugate sinusoidal tooth profile, the reference sinusoidal tooth profile and the conjugate sinusoidal tooth profile have a conjugate relationship with each other; The tooth profile curve of the reference sine tooth profile is the reference sine curve 1, and the reference sine curve 1 is a continuous multi-wave closed curve that is periodically distributed in the plane, and its parameter equation is:

[0057]

[0058] According to the reference curve, the meshing line equation can be obtained from the principle of gear meshing:

[0059]

[0060] By further coordinate transformation, the parametric equation of the conjugate sinusoidal tooth profile can be obtained. After determining the number of teeth Z 2 , modulus m 2 , angular position coordinates center distance a 0 After that, the corresponding tooth...

Embodiment 2

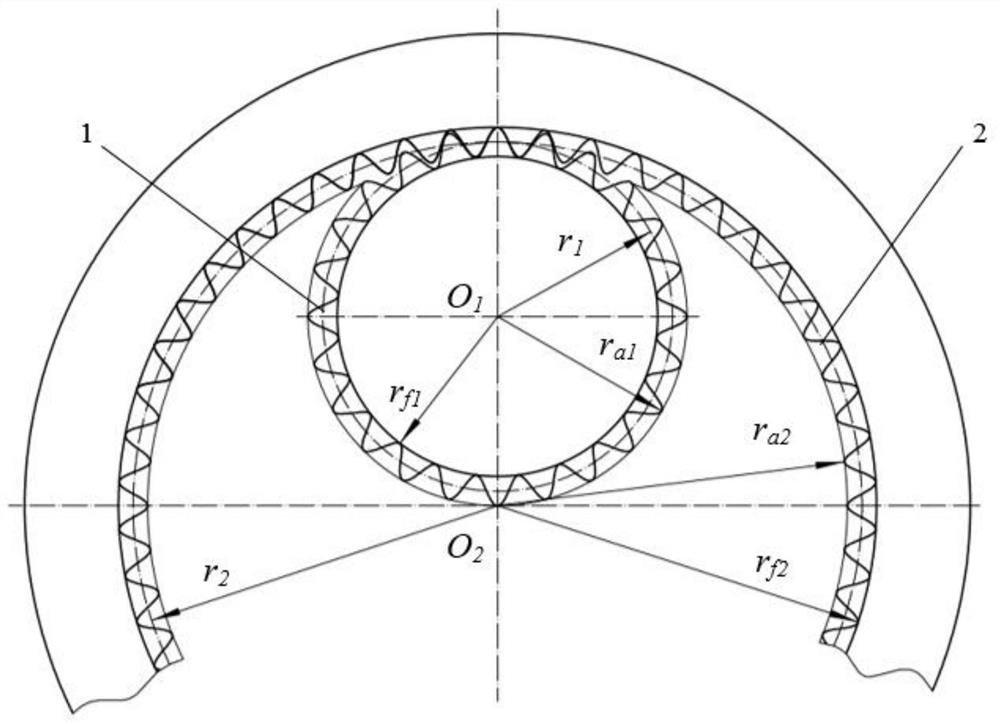

[0080] like image 3 As shown, the gear pair II adopts internal meshing, and its parameters are shown in Table 2:

[0081] Table 2

[0082]

[0083] After substituting the above parameters into the above tooth profile equation, it can be obtained as follows image 3 As shown in the gear pair II, it can be seen that the novel sinusoidal profile gear in the present invention is multi-tooth meshing during meshing. The transmission ratio of the gear pair during fixed shaft transmission: i 12 =Z 2 / Z 1 = 25 / 12.

[0084] The invention is a novel continuous sinusoidal tooth profile and its gear pair, including the reference sinusoidal tooth profile, the conjugate sinusoidal tooth profile and the gear pair formed by the mutual meshing of the gears formed by the two tooth profiles. A series of parameters can be selected during design, such as: number of teeth, module, tooth height coefficient, tooth thickness influence coefficient, center distance, etc., in order to design the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com