Instrument device for detecting bearing inner diameter runout

A bearing and inner diameter technology is applied in the field of instruments and devices for detecting the runout of the inner diameter of the bearing, which can solve the problems of inaccuracy and false values, and achieve the effect of reducing work intensity and accurate measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

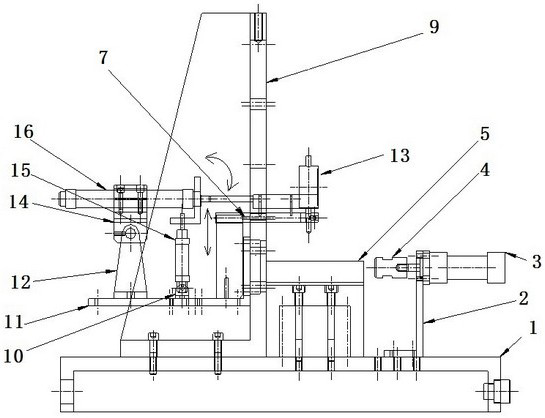

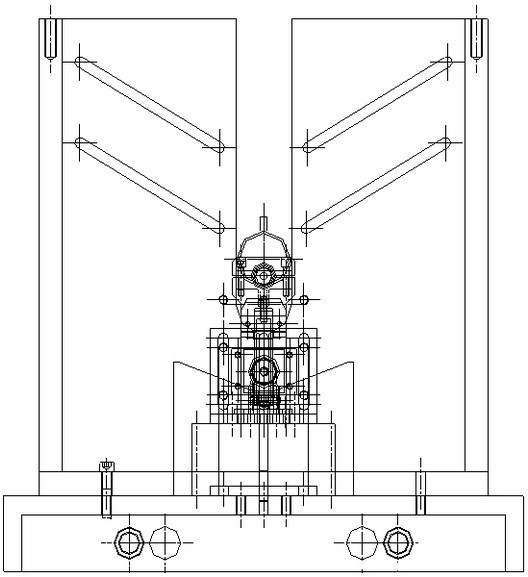

[0026] The instrument device for detecting the runout of the inner diameter of the bearing includes a base 1, a support plate 9 is fixed on the base 1, and a structure for fixing the bearing outer ring of the bearing to be tested is arranged on one side of the support plate 9; a supporting plate 11 is fixed on the other side of the support plate 9, The second cylinder swivel seat 10 and the third cylinder swivel seat 12 are installed on the upper part of the supporting plate 11, the upper shaft of the second cylinder swivel seat 10 is connected to one end of the second cylinder 15, and the upper shaft of the third cylinder swivel seat 12 is connected to the third cylinder fixed seat 14. The third cylinder fixed base 14 is detachably connected to the third cylinder 12, the piston rod of the second cylinder 15 drives the third cylinder 16 and the third cylinder fixed base 14 rotates relative to the third cylinder rotating base 12, the third cylinder 16. The piston rod is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com