Mobile phone display screen pressure-bearing capacity detection device and use method thereof

A pressure-bearing capacity and detection device technology, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as inconvenient operation, difficult handling, and inability to detect the pressure-bearing capacity of mobile phone display screens. To achieve the effect of local operation convenience and speed up detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "inner", "middle", "left", "right" and "one" quoted in this specification are only for the convenience of description, and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

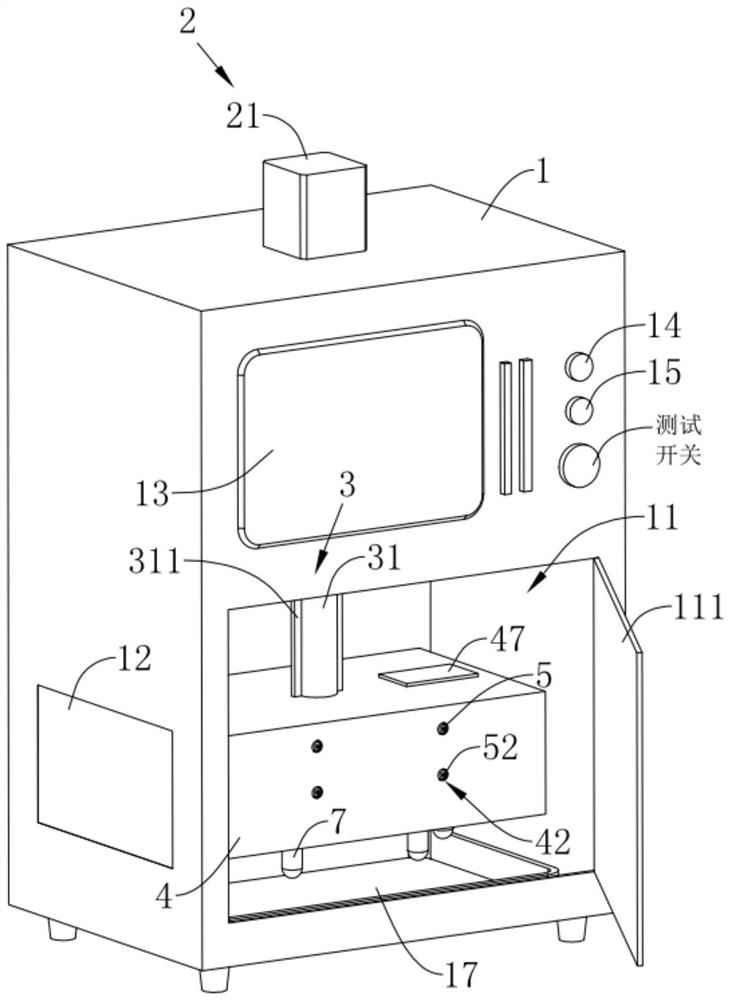

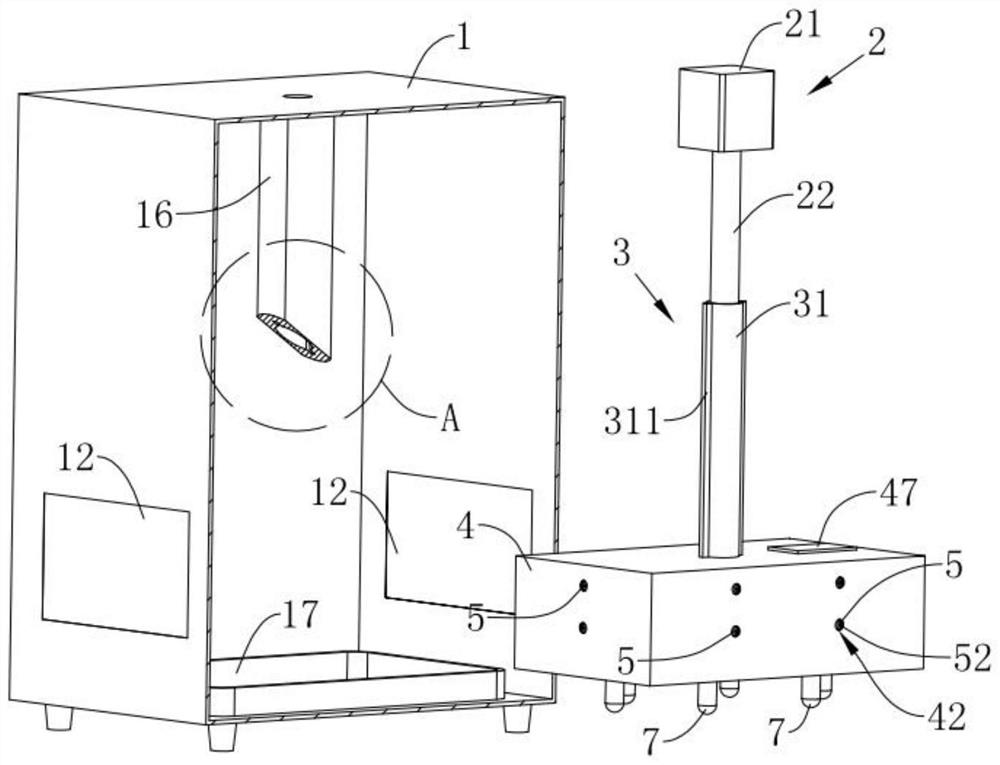

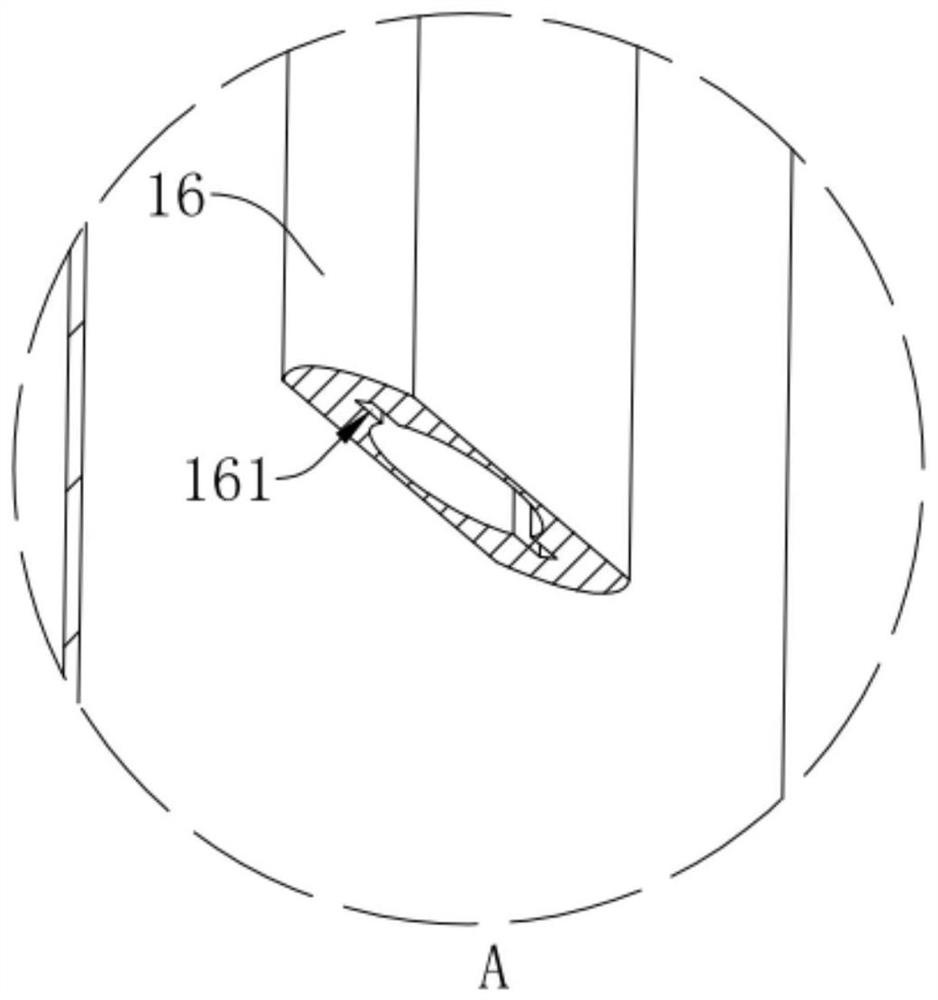

[0033] refer to Figure 1 to Figure 3 As shown, a mobile phone display pressure-bearing capacity detection device includes a rectangular parallelepiped and hollow housing 1, the housing 1 is provided with a storage tray 17 and a driver 2, and the storage tray 17 is fixedly connected to the inner bottom surface of the housing 1 , the opening of the storage tray 17 is set upwards, the driving end of the driving member 2 face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com