Film defect detection method based on improved attention mechanism

A defect detection and attention technology, applied in the field of video image processing and pattern recognition, can solve the problems of long detection time, small film defect target, complex calculation, etc., to improve the accuracy, difficulty and expressiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

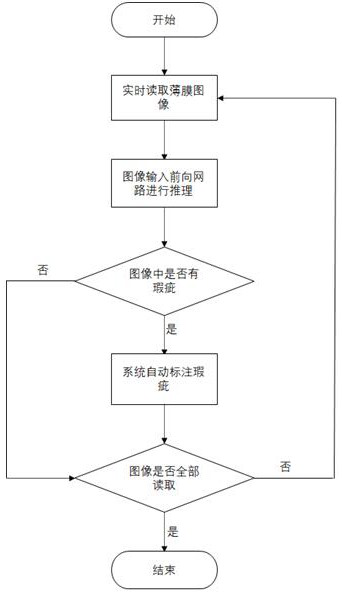

[0031] The invention provides a method for thin film defect detection based on an improved attention mechanism. The workflow of the thin film detection system is as follows: figure 1 As shown, the steps are as follows:

[0032] (1) The system reads the film image in real time;

[0033] (2) Input the image into the network model for forward reasoning;

[0034] (3) The system judges whether there is a defect in the film image according to the reasoning result, if there is a defect, then enter step (4), otherwise enter step (5);

[0035] (4) The system marks the defects with a rectangular frame and prompts that the image has defects;

[0036] (5) The system judges whether there are unread images, if so, returns to step (1), otherwise ends the detection. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com