Motor starting control method and device, and electrical equipment

A technology for electrical equipment and starting circuits, applied in the direction of a single multi-phase induction motor starter, motor generator/starter, etc., can solve the problems of switching current, equipment impact, etc., to reduce impact, improve stability and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

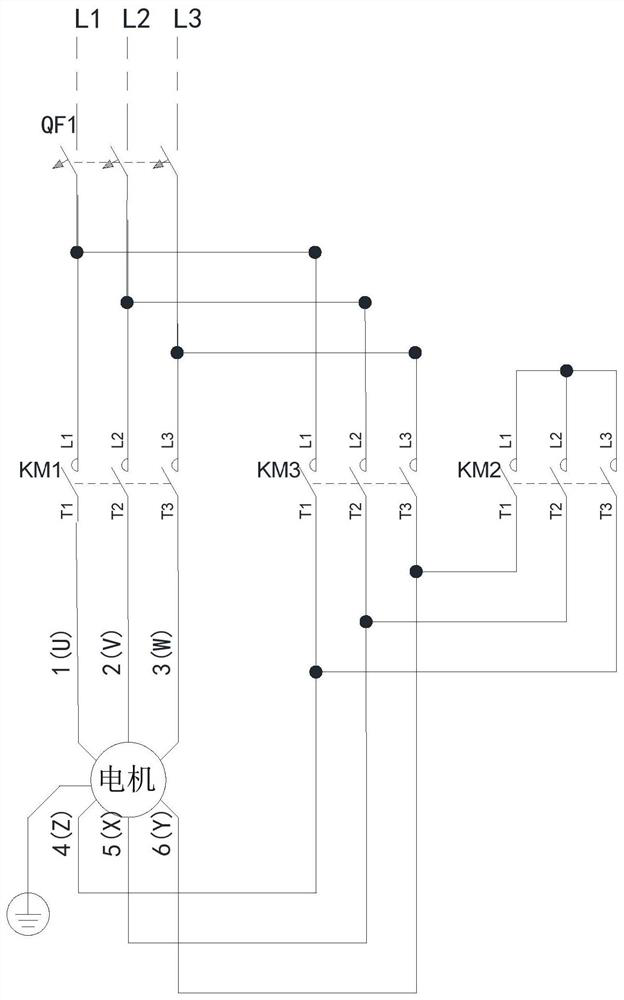

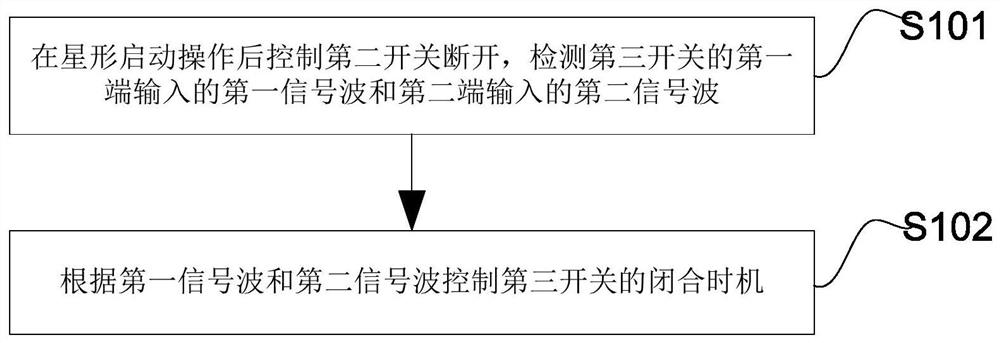

[0049] This embodiment provides a motor starting control method, which is applied to a star-delta starting circuit, figure 1 It is a structural diagram of a star-delta starting circuit according to an embodiment of the present invention, as figure 1 As shown, the star-delta starting circuit includes a first switch KM1, a second switch KM2 and a third switch KM3, and the three-phase winding of the motor has six external terminals: 1(U), 2(V), 3(W), 4 (Z), 5(X), 6(Y) (the motor with a rated voltage of 380V is taken as an example below).

[0050] Star start: By closing the first switch KM1, 1 (U), 2 (V), and 3 (W) are respectively connected to the first phase L1, the second phase L2, and the third phase L3 of the power supply, and connected to 380V three-phase AC At the same time, the second switch KM2 is closed to connect terminals 4(Z), 5(X), and 6(Y). At this time, the voltage of each phase winding is 220, which is greatly reduced compared with directly adding 380V starting c...

Embodiment 2

[0061] This embodiment provides another motor starting control method. In order to accurately control the closing timing of the third switch to control the magnitude of the switching current, the above step S102 includes: obtaining the first signal wave input from the first terminal of the third switch and the first signal wave The phase difference of the second signal wave input at the two terminals; according to the phase difference between the first signal wave and the second signal wave, the third switch is controlled to be closed or kept open.

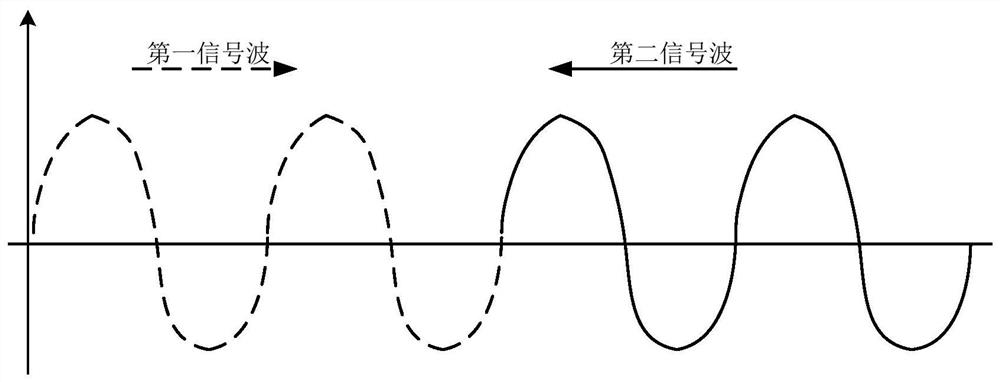

[0062] image 3 It is a waveform diagram of a first signal wave and a second signal wave according to an embodiment of the present invention, such as image 3 As shown, the phase difference between the first signal wave and the second signal wave is zero, that is, the trough of the first signal wave overlaps with the trough of the second signal wave, and the peak of the first signal wave overlaps with the peak of the second signal...

Embodiment 3

[0069] This embodiment provides another motor starting control method, which is applied to the above-mentioned star-delta starting circuit, wherein the star-delta starting circuit is as mentioned above figure 1 shown in . The star-delta start is divided into two stages. In the first stage, the first switch KM1 and the second switch KM2 are closed, and the motor completes the star-shaped start; then the switch KM2 is disconnected, and the switch KM3 is closed, and the motor completes the star-delta switch and turns into a delta. run phase. During the process from the disconnection of KM2 to the pull-in of KM3, there will be a short period of time, and in this period of time, both the second switch KM2 and the third switch KM3 are turned off. During this period of time, the speed of the motor has reached a very high level, and the motor will still maintain this high-speed rotation. The motor turns into a generator and starts to provide electromotive force to the outside, but be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com