Furniture polishing device provided with clamping mechanism

A technology for clamping mechanism and furniture, applied to used abrasive treatment devices, abrasives, manufacturing tools, etc., can solve the problems of rare furniture application, lack of automatic polishing furniture, etc., to achieve stable transportation process of furniture, reduce disassembly burden, The effect of increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

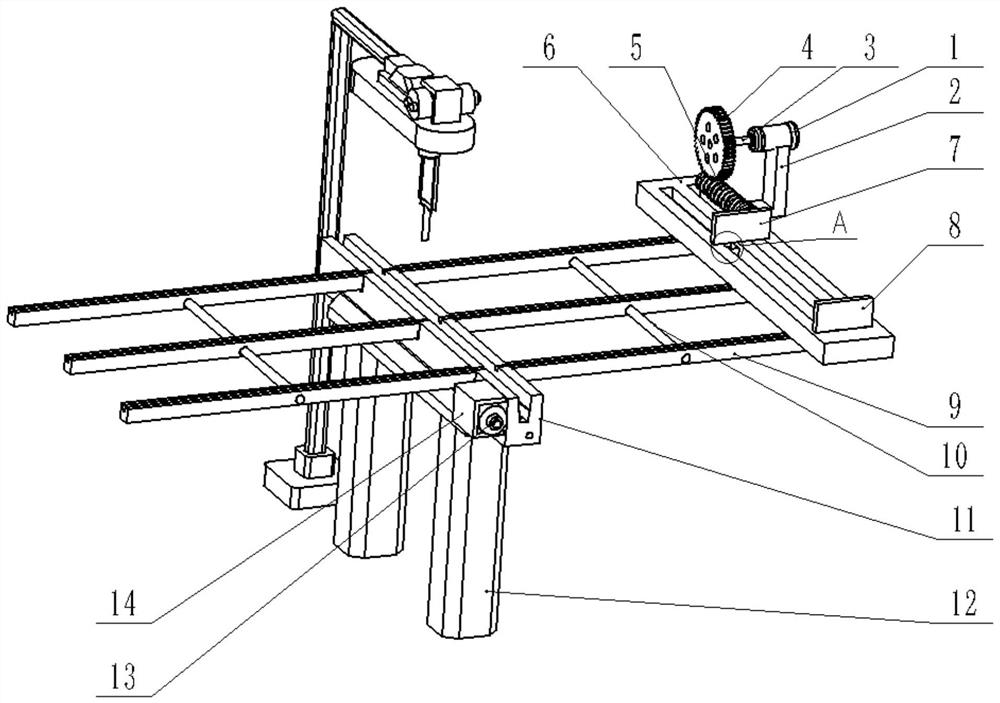

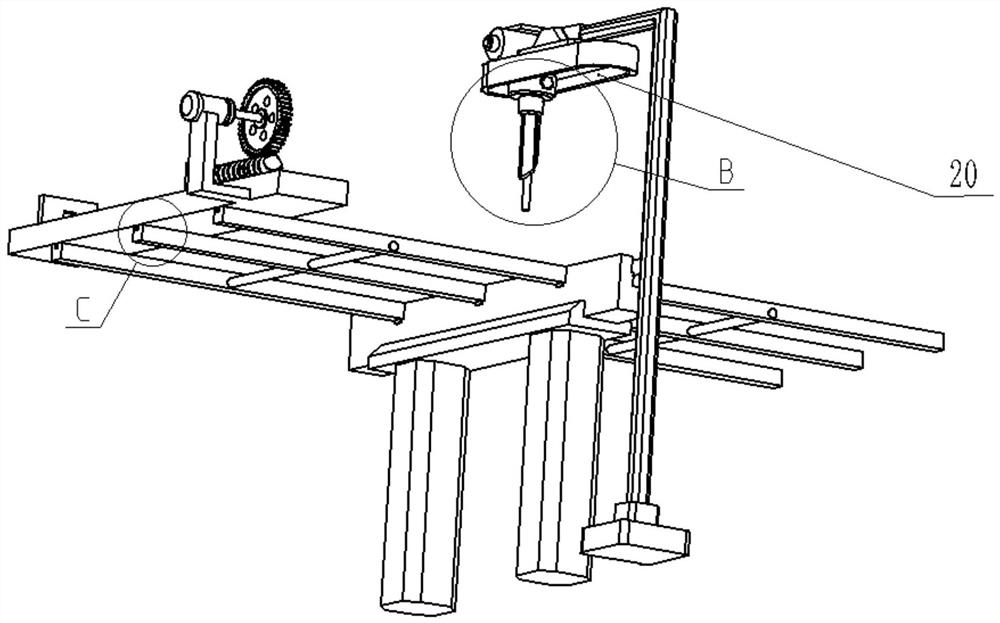

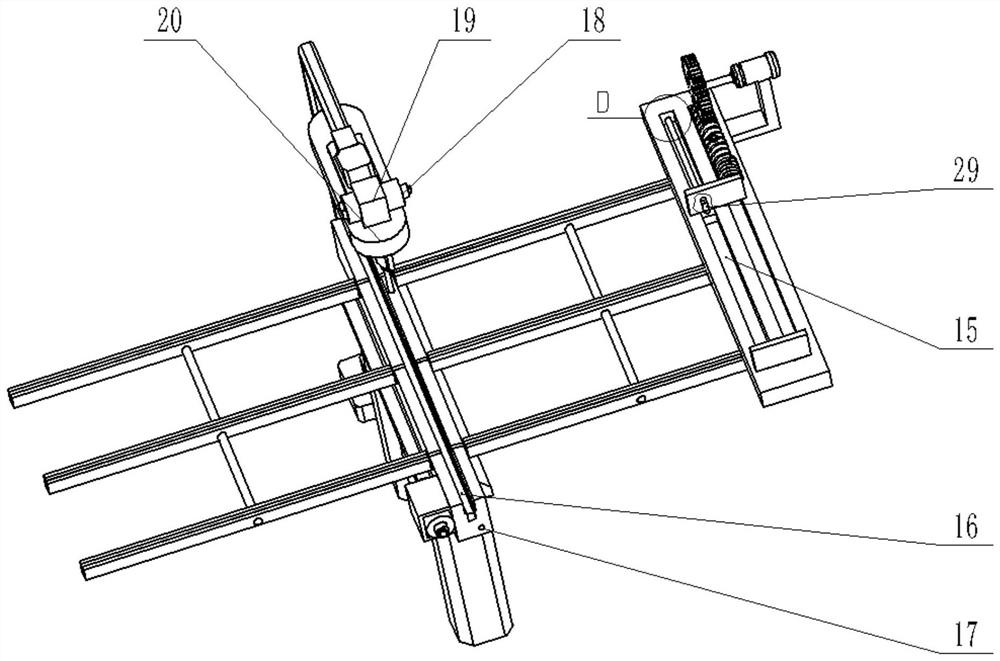

[0028] A furniture polishing device equipped with a clamping mechanism, which is composed of an automatic clamping mechanism, an automatic polishing mechanism and a transport rail mechanism. The automatic clamping mechanism has a motor 1, a motor bracket 2, a motor output shaft 3, Worm wheel 4, worm screw 5, clamping base 6, movable block 7, fixed block 8, sliding guide rail 15, pressure sensor 23, guide rail convex track 28, first hydraulic rod 29, second hydraulic rod 30 and slider 31 structure , the described automatic grinding device has a hollow storage cavity 16, a round hole 17, an electromagnetic motor 18, a motor clamp frame 19, an electromagnetic motion groove 20, a support frame 21, a support base 22, a spray gun movable block 24, and an electromagnetic magnet 25 , spray gun telescopic shaft 26 and spray gun nozzle 27 structures, on the described transport guide rail mechanism, there are moving guide rail concave tracks 9, connecting cylinder 10, semi-hollow support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com