Planet gear grinding tool

A technology of planetary gear and gear grinding, which is applied in the direction of gear tooth manufacturing devices, gear teeth, gear cutting machines, etc. It can solve the problems of easy breakage of expansion sleeves and difficulties in workpiece clamping, and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

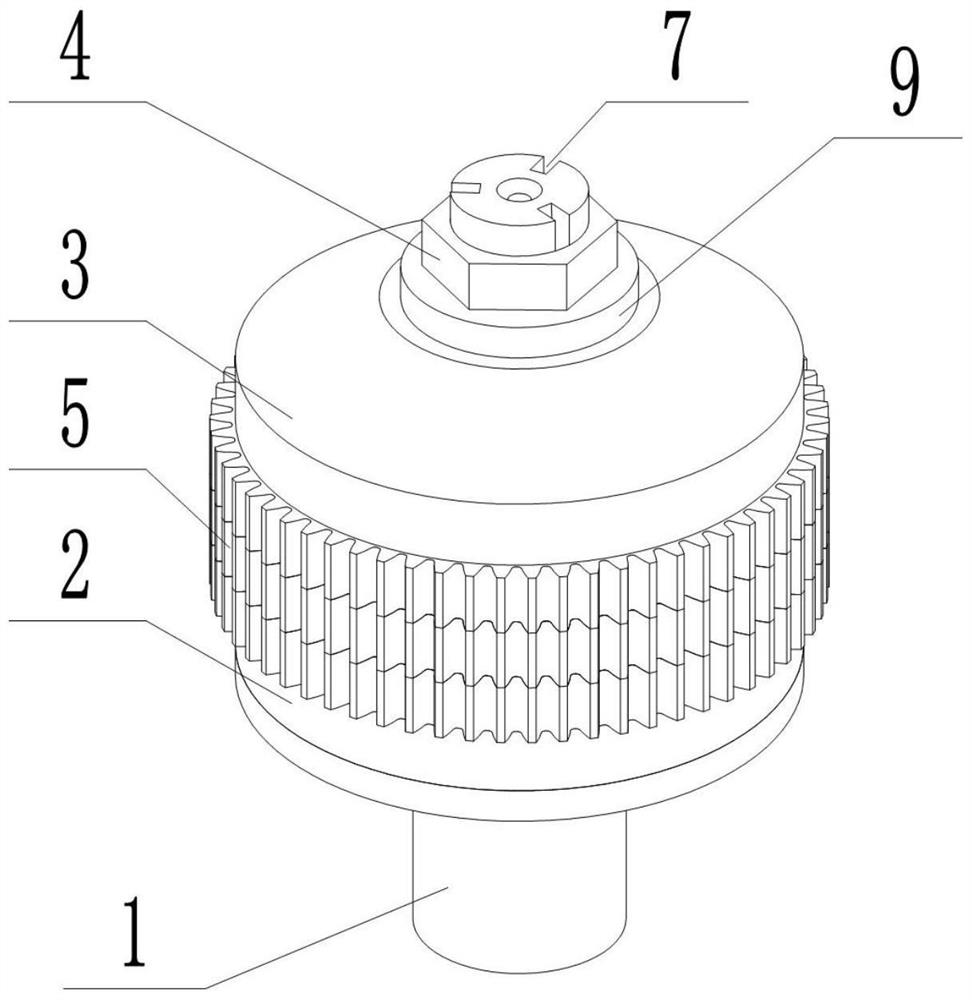

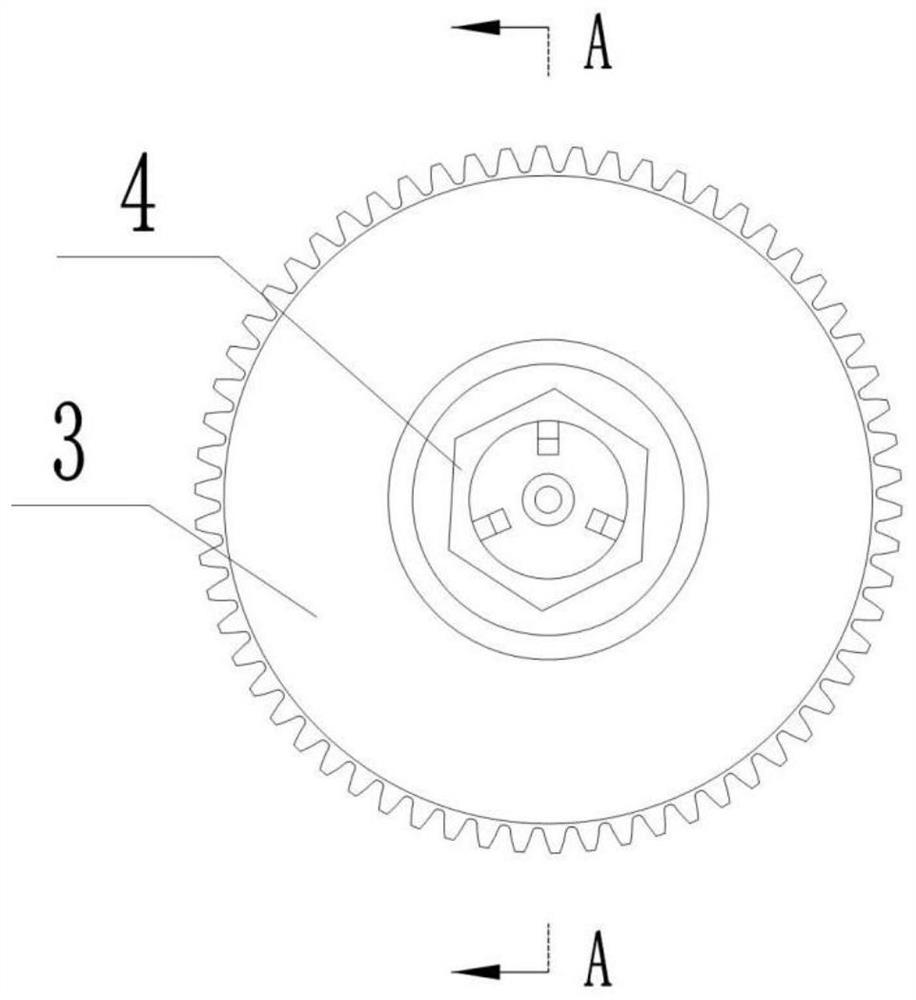

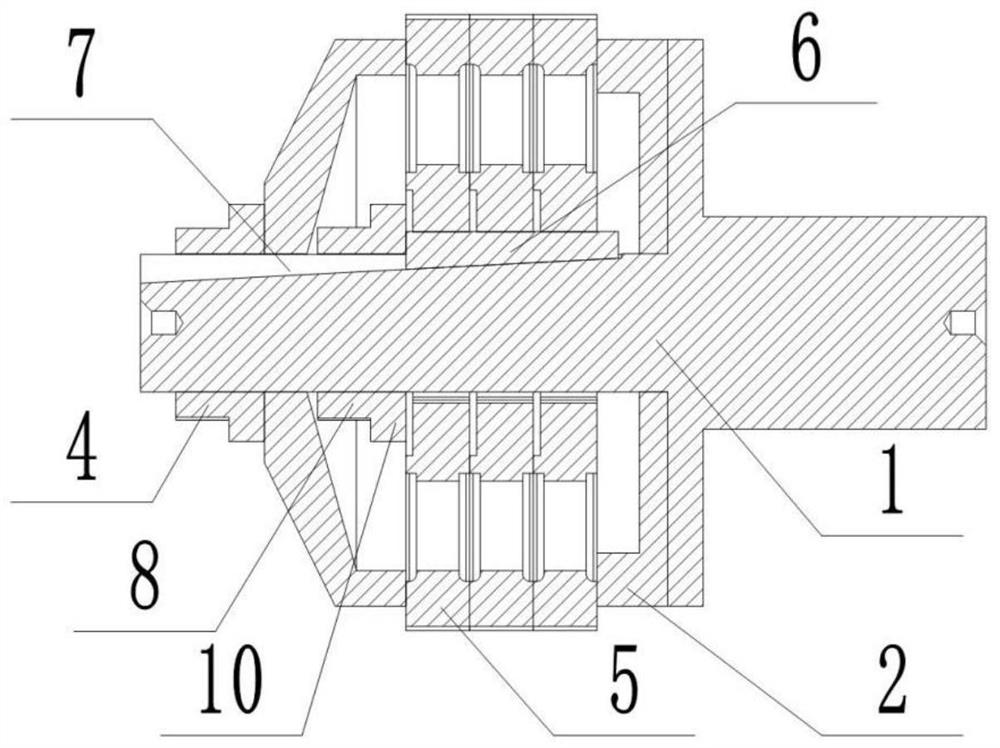

[0020] Such as Figure 1 to Figure 5 As shown, a gear grinding tool for planetary gears includes a shaft core 1, on which a support pad 2, a gland 3 and a No. 2 and the gland 3, and the planetary gear 5 is set on the shaft core 1, the support pad 2 and the No. 1 fixing nut 4 are both threaded with the shaft core 1, and the shaft core 1 is provided with a number of circumferentially uniform axial cones. Strip groove 7, tapered strip 6 is matched in the tapered strip groove 7, the end of the tapered strip 6 away from the shaft core 1 is located between the two adjacent teeth on the inner side of the planetary wheel 5, and the upper end of the tapered strip 6 is provided for pressing The second fixed nut 8 of the tapered strip 6 and the planetary wheel 5 is threadedly connected with the shaft core 1 .

[0021] A No. 1 gasket 9 is provided between the No. 1 fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com