High-degree-of-freedom multi-angle adjustable quick tool change mechanism based on reliability design

A technology of tool change mechanism and degree of freedom, applied in metal processing equipment, large fixed members, metal processing machinery parts, etc., can solve the problems of unsuitable machine tools, cumbersome tool changes, low efficiency of tool switching, etc., and achieve overall operation It is convenient and effective, guarantees the operation accuracy and avoids the effect of operation interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

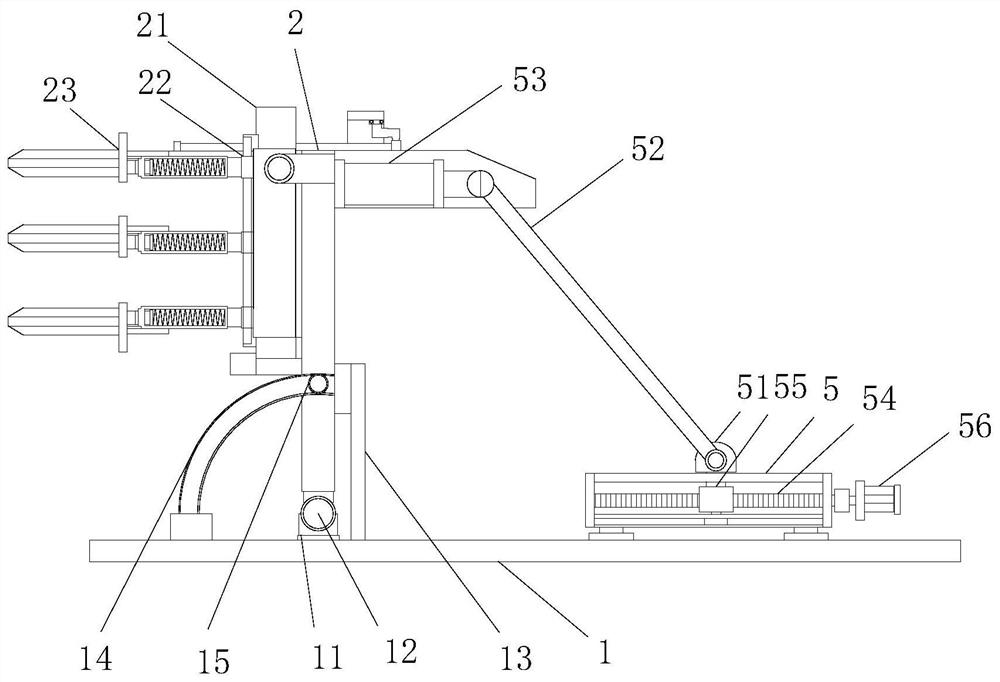

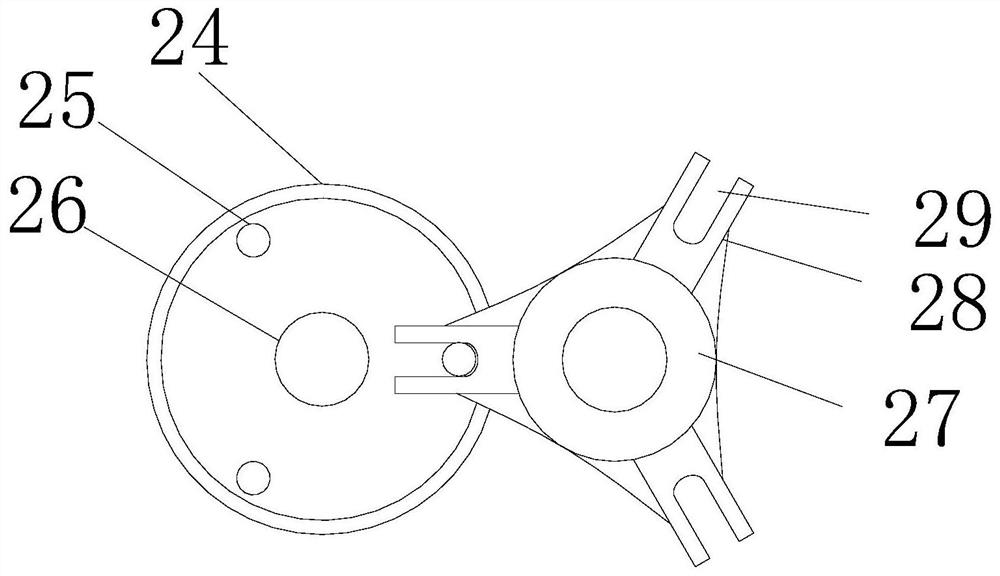

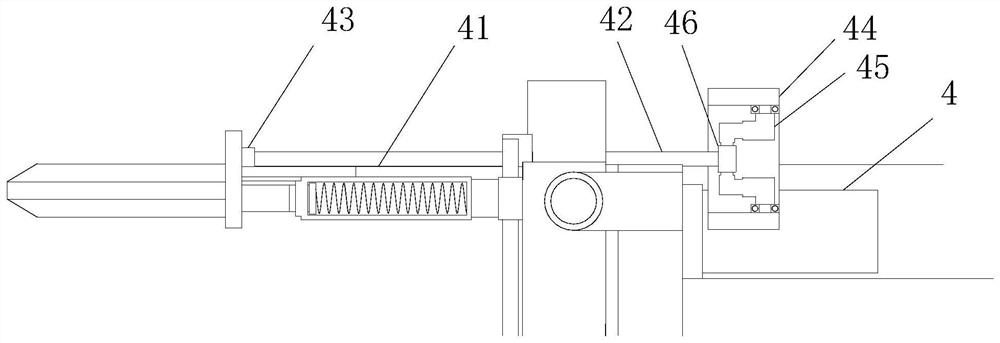

[0031] see figure 1 and figure 2 , a high-degree-of-freedom multi-angle adjustable quick tool change mechanism based on reliability design, including a base 1 and a tool holder 2, a tool change holder 21 is installed on the tool holder 2, and the main body of the tool change holder 21 It is a tool change carousel 24, and several positioning blocks 22 are installed at equal angles on the tool change carousel 24. Corresponding tool holders 23 are installed on the positioning blocks 22, and corresponding card holders are installed on the installation positions of the tool holders 23. The engaging cylinder 25 is installed on the other side of the tool change carousel 24, and the side of the tool change frame 21 is provided with a driving turntable 27, and a number of external parts are installed at equal angles along the position of the driving turntable 27. Both the edge block 28 and the outer edge block 28 are provided with fitting notches 29 , and the fitting notches 29 are m...

Embodiment 2

[0036] see figure 1 , this embodiment is a further optimization of Embodiment 1. On the basis of it, a support seat 11 is installed on the base 1, and the tool holder 2 is installed on the support seat 11 through a rotating shaft 12. The support seat 11 Both sides are equipped with a positioning frame 13, the positioning frame 13 is equipped with a steering guide rail 14, the steering rail 14 is an arc structure and has a built-in arc notch, and the two side walls of the tool holder 2 are equipped with The slide bolt 15, the tool holder 2 is fitted and installed in the steering guide rail 14 through the slide bolt 15 on the side wall.

[0037] The base 1 is provided with an angle alternation frame 5, and the edge of the angle alternation frame 5 is movable through a chute to install a slider 51, and the slider 51 is externally connected with an adjustment rod 52, and the adjustment rod 52 The front end of the rod is respectively fixed and installed with the two side plates of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com