Clamp special for steel shovel polishing and process

A special fixture and shovel technology, used in grinding/polishing equipment, surface-polished machine tools, manufacturing tools, etc., can solve problems such as low efficiency, inability to continuous production, inability to realize automated and intelligent production, etc., to improve efficiency, Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

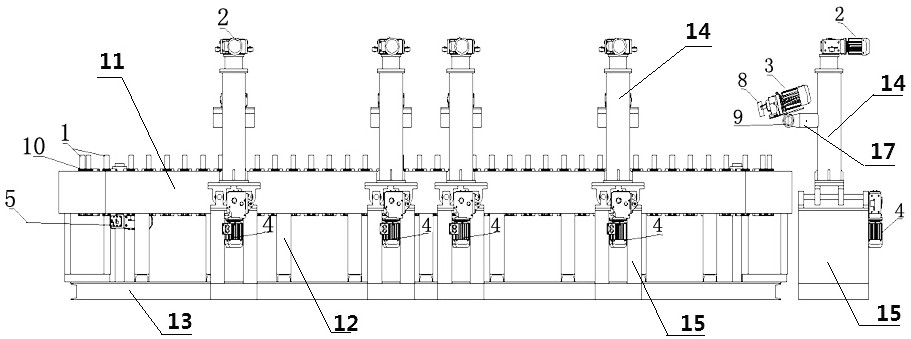

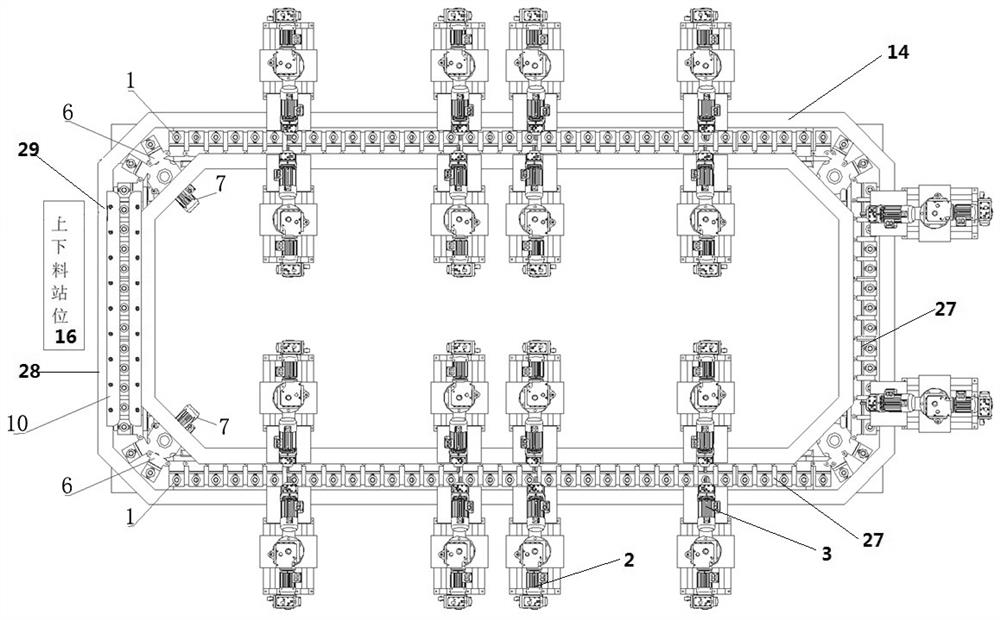

[0019] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

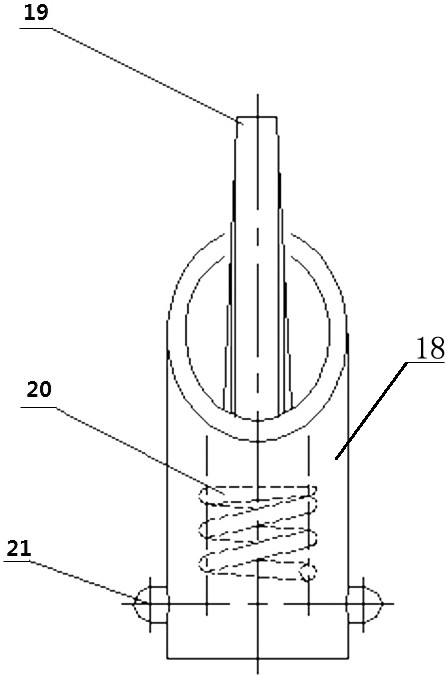

[0020] A special jig for steel shovel polishing, including an outer cylinder 18, an inner cylinder 19, a return spring 20, a pressure plate 26 and a lug 21. The outer cylinder 18 and the inner cylinder 19 form a sleeve structure, and the bottom is fixedly connected together. The inner cylinder 19 is a conical frustum tube with a taper. The upper part of the inner cylinder 19 is provided with a plurality of longitudinal opening grooves 24. The outer diameter of the inner cylinder 19 is larger at the bottom and smaller at the top, and a cylindrical plug body 25 is arranged inside. The inner diameter of the upper mouth of the inner cylinder body 19 is less than the outer diameter of the bolt body 25, and the inner diameter of the lower mouth of the inner cylinder body 19 is greater than the outer diameter of the bolt body 25; The inner diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com