A kind of preparation process of concrete

A preparation process and concrete technology, which is applied in the field of concrete, can solve problems such as gravel blockage, finished materials are easily mixed with large crushed stones, and affect the construction period of concrete, and achieve the effect of reducing the requirement of uniform aggregate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

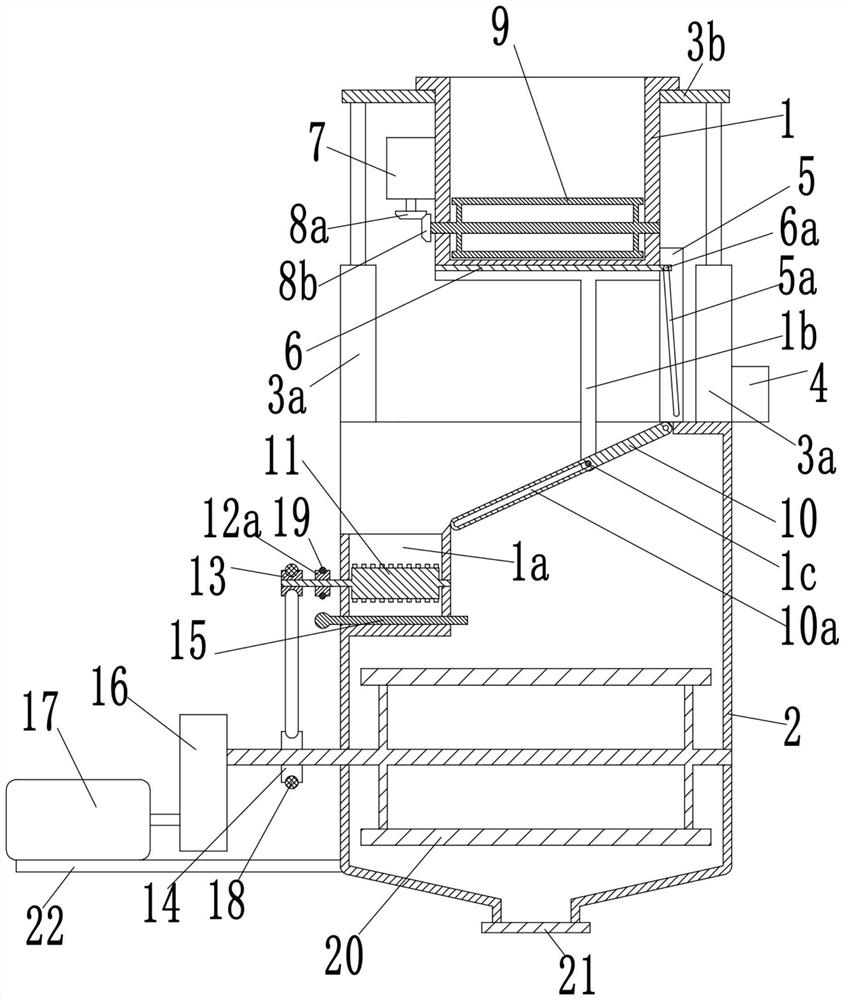

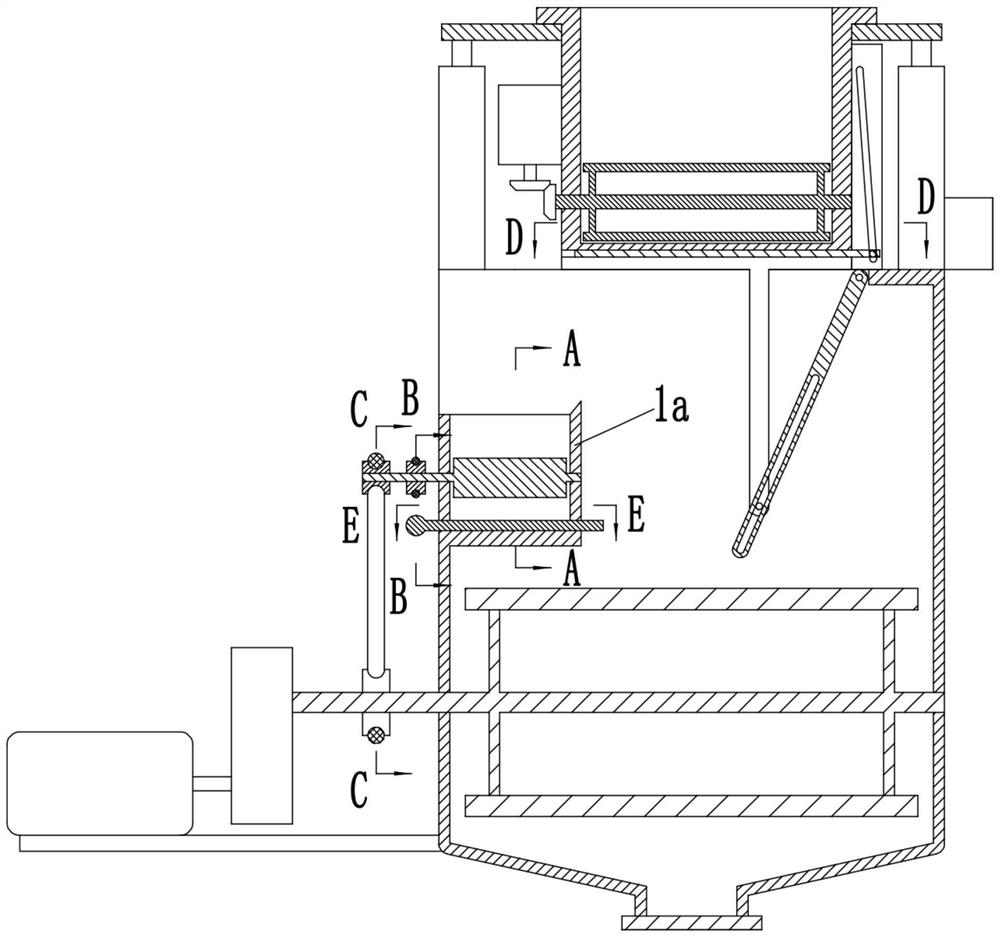

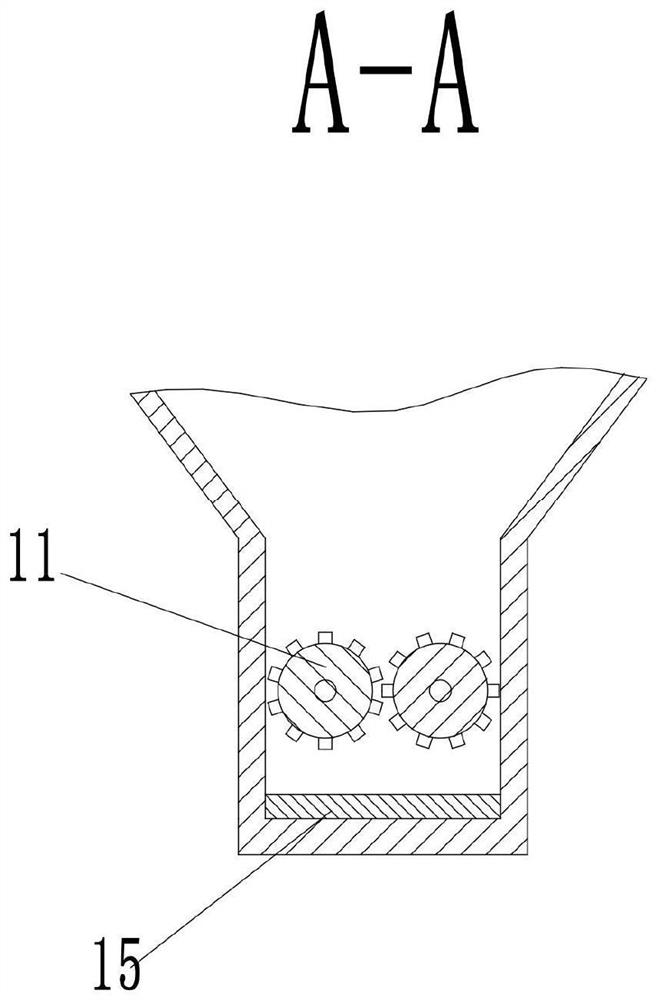

[0031] see Figure 1-9 As shown, the present invention provides a preparation process for concrete. The equipment used in the preparation process includes a shell 2. The upper end of the shell 2 is a feeding port and the lower end is a discharge port. The lower end of the shell 2 is A bottom cover 21 is provided at the discharge opening; the housing 2 is provided with a first stone screening assembly above the feeding opening, and the housing 2 is provided with a second stone screening assembly on the inner wall of the feeding opening; The housing 2 is provided with a stirring assembly; the preparation process includes the following steps,

[0032] Step 1, controlling the downward movement of the first stone screening assembly to open the feeding port, and adding the cementitious material, water, admixtures and admixtures required for preparing concrete into the shell 2;

[0033] Step 2: put crushed stones into the first stone screening assembly, control the first stone scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com