Biodegradable film master batch mixing device

A biodegradable film and mixing device technology, applied in the field of biodegradable film master batch mixing devices, can solve the problems of contamination with large dust and impurities, inability to handle impurities, affecting the quality of biodegradable films, etc., to improve air quality, improve quality, The effect of omitting manual steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

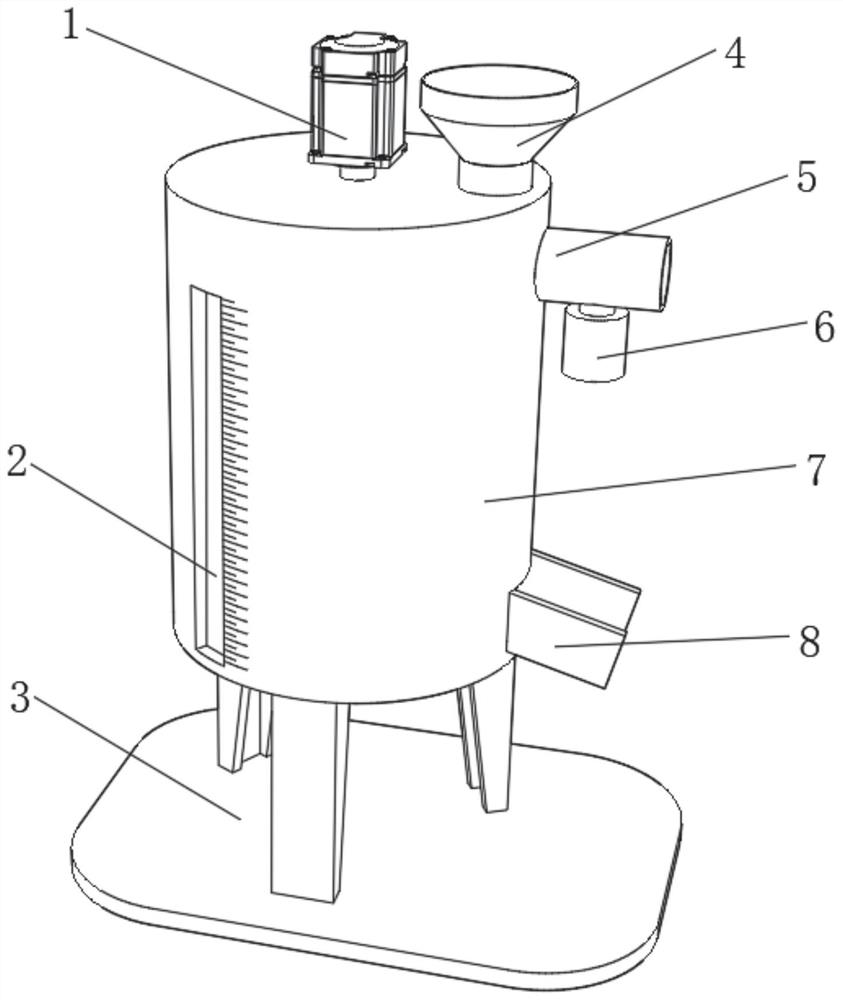

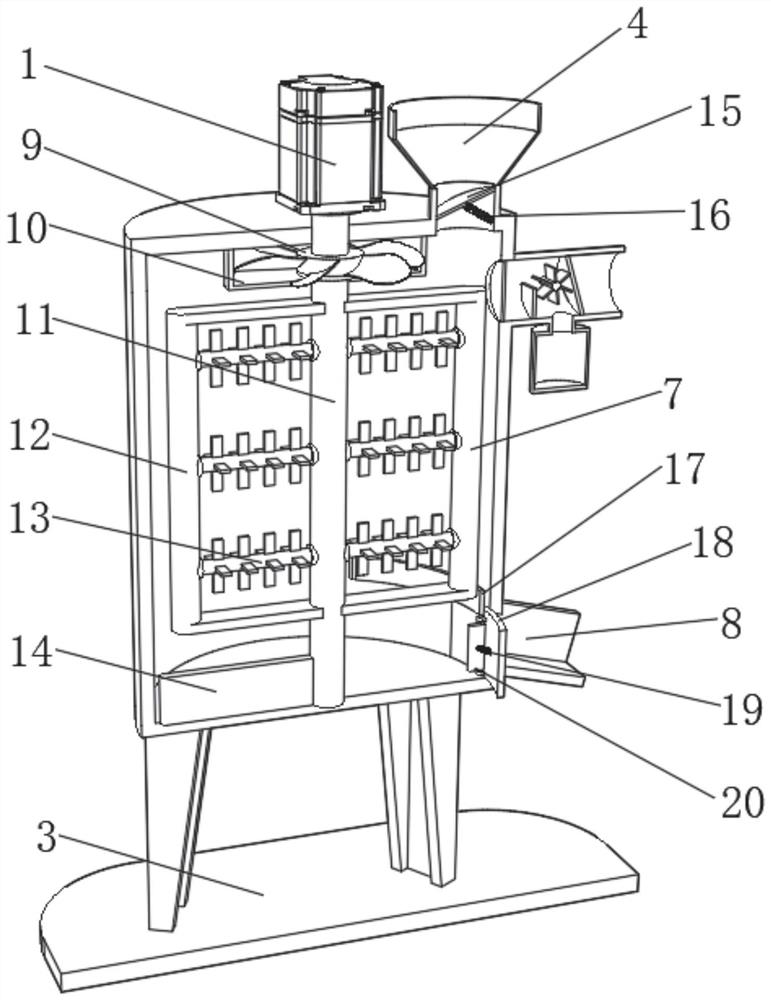

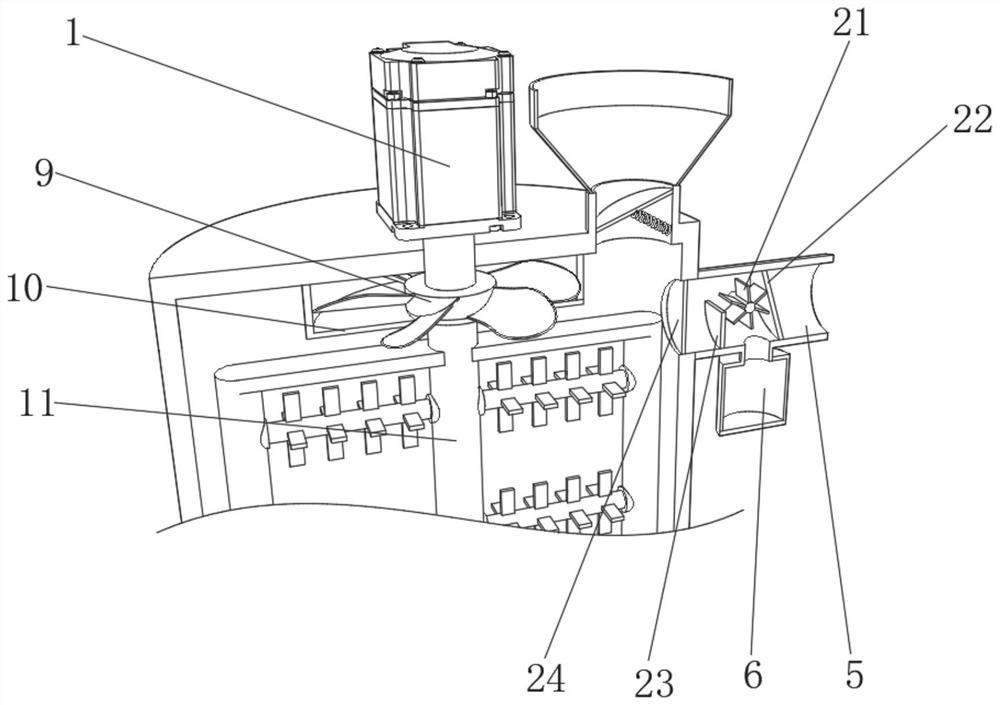

[0025] refer to Figure 1-Figure 3 , a biodegradable film master batch mixing device, including a base 3, the upper surface of the base 3 is fixed with a plurality of support columns by bolts, the top of the support columns is fixed with a tank 7 by bolts, and the top inner wall of the tank 7 is fixed by bolts There is a protective cover 10, the top outer wall of the tank body 7 is fixed with a motor 1 by bolts, and one end of the output shaft of the motor 1 is fixed with a connecting shaft 11 by bolts, and the connecting shaft 11 passes through the top of the tank body 7 and is connected to the top of the tank body 7 in rotation , one side of the connecting shaft 11 is fixed with a fan 9 by bolts, the fan 9 can rotate together with the rotation of the motor 1, thereby generating an air flow to the outside of the tank body 7, and the fan 9 is located inside the protective cover 10, and the protective cover 10 It can prevent the masterbatch from jamming the fan 9 during mixing ...

Embodiment 2

[0029] refer to Figure 4, a biodegradable film masterbatch mixing device, also includes a sleeve 28, one side of the sleeve 28 is provided with two connection holes 29, and the sleeve 28 communicates with the tank body 7 through the connection holes 29, and settles in the tank body 7. The masterbatch at the bottom can enter the inside of the sleeve 28 through the connecting hole 29. One side of the sleeve 28 is rotated and connected with a connecting rod, and one side of the connecting rod is fixed with a spiral piece 27 by bolts. The first pulley 25, a side of the first pulley 25 is wound with a belt, and one end of the connecting rod is key-connected with a second pulley 26, and the second pulley 26 is connected with the belt, through the first pulley 25 and The setting of the second pulley 26 makes the spiral piece 27 rotate together with the rotation of the motor 1, thereby lifting the masterbatch at the bottom of the sleeve 28 to the top of the tank body 7, thereby perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com