Blind area anti-collision control system and method and excavator

A control system and anti-collision technology, applied in the field of excavators, can solve problems such as high noise, affecting normal operation, and difficult for drivers to observe, and achieve the effect of reducing the accident rate, improving operation safety and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

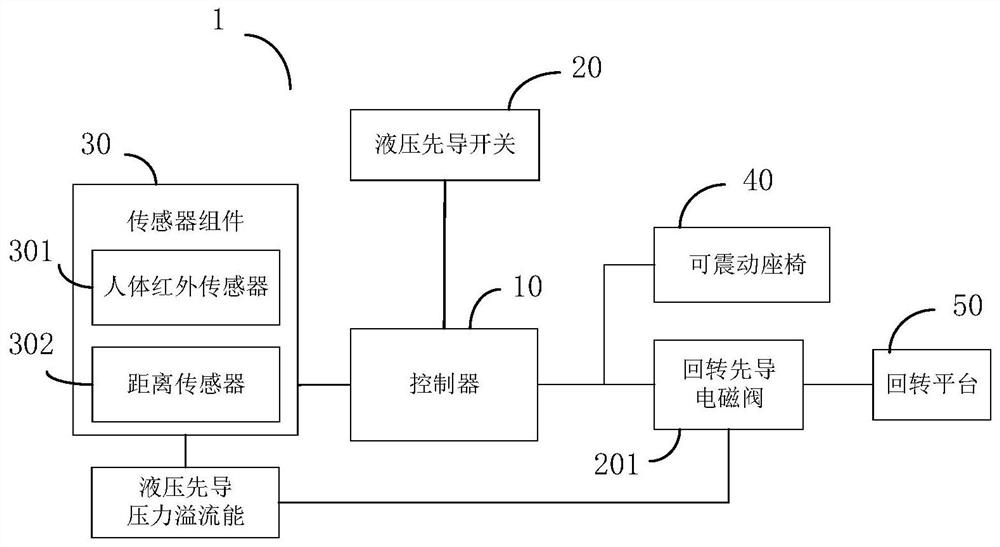

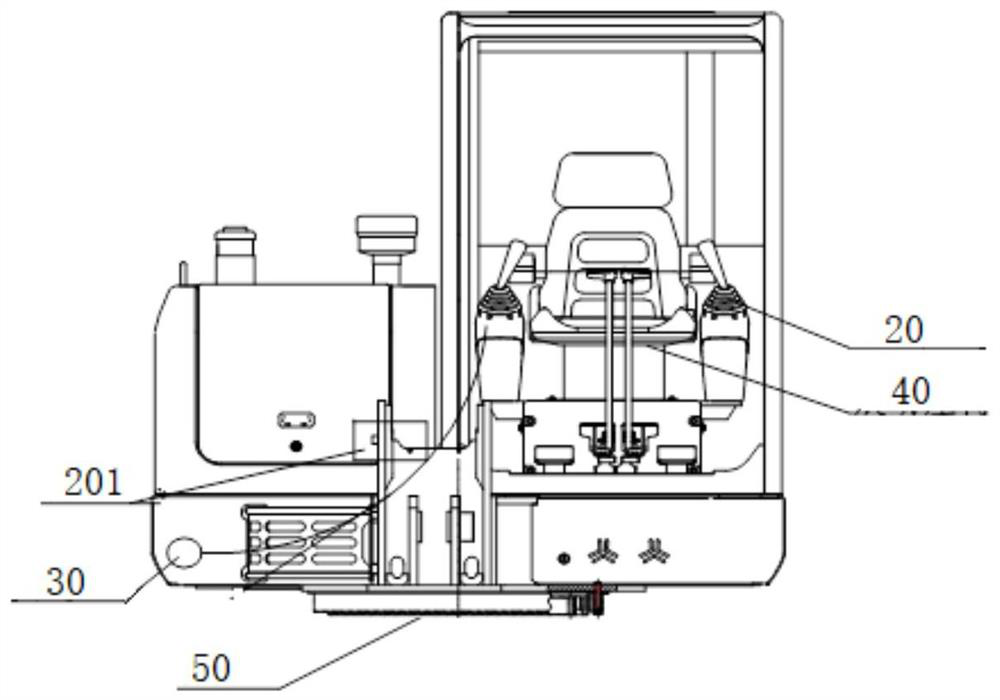

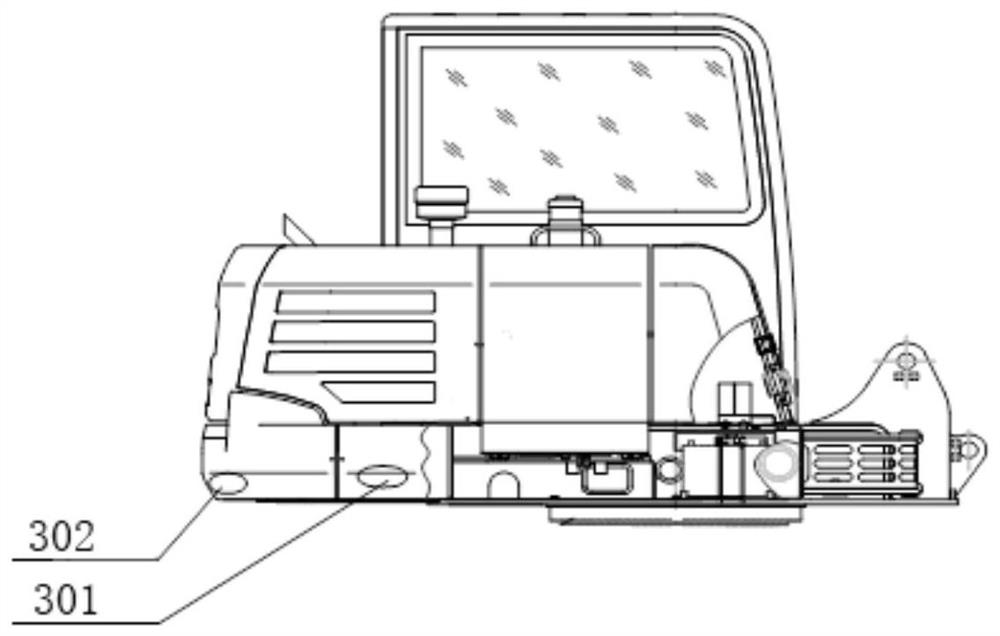

[0038] Please refer to figure 1 , this embodiment proposes a blind zone anti-collision control system, which is mainly applied to excavators. This method can effectively solve the blind zone collision problem of excavators, thereby reducing the occurrence of accidents and improving operation safety and work efficiency.

[0039] Exemplarily, as figure 1 As shown, the blind spot anti-collision control system 1 includes: a controller 10 , a hydraulic pilot switch 20 and a sensor assembly 30 , and the hydraulic pilot switch 20 and the sensor assembly 30 are electrically connected to the controller 10 respectively. Wherein, the hydraulic pilot switch 20 is used as the control switch of the entire excavator. Usually, when the hydraulic pilot switch 20 is turned on, the controller 10 will default to the excavator to enter the power-on state. To provide working energy; on the contrary, when the hydraulic pilot switch 20 is closed, the controller 10 will assume that the excavator is i...

Embodiment 2

[0058] Please refer to Figure 4 , this embodiment proposes a blind spot anti-collision control method, which can be applied to the blind spot anti-collision control system of an excavator. The pilot switch 20 and the sensor assembly 30 are respectively electrically connected to the controller 10 . Optionally, the system further includes a vibrator seat 40 connected to the controller 10 .

[0059] Exemplarily, the blind spot anti-collision control method includes:

[0060] Step S110, when the hydraulic pilot switch 20 is turned on, the anti-collision detection mode is started.

[0061] In step S120, the environmental parameters of the blind area are collected in real time through the sensor assembly 30 .

[0062] Step S130, judging whether the blind spot environmental parameter is within the preset blind spot warning range.

[0063] Step S140, if it is within the preset blind spot warning range, control the connected vibrator seat 40 to vibrate to remind the driver to pay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com