Flexible turning-around device for small cigarette packets

A technology of a head turning device and a cigarette pack, which is applied in the field of the tobacco industry, can solve the problems of tobacco leakage, a cavity at the end, and quality problems, and achieves the effects of high conveying efficiency and reduced impact pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

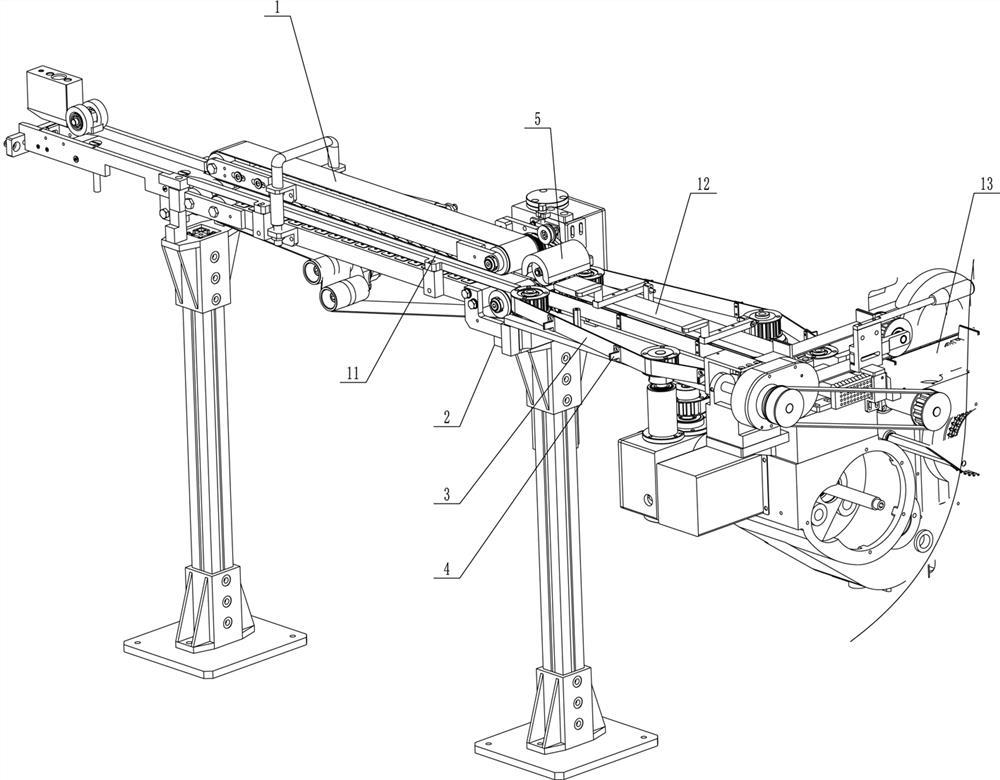

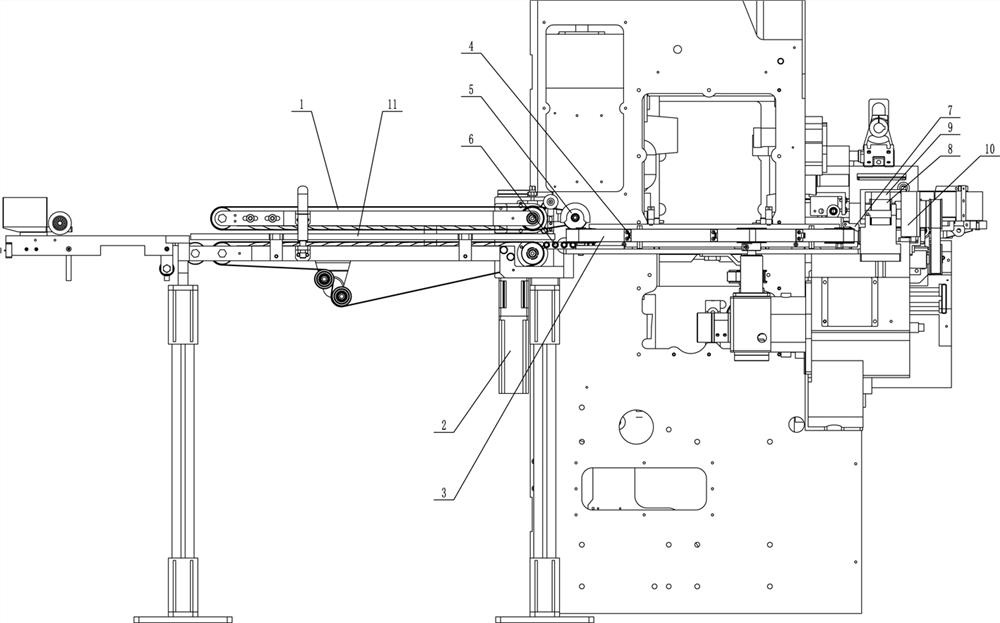

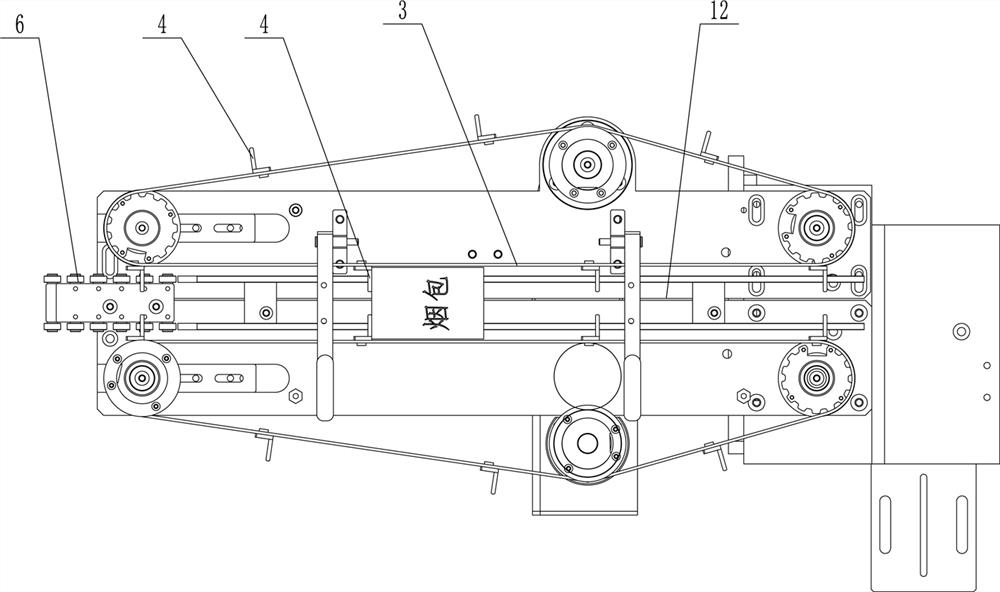

[0036] Such as Figure 1-Figure 8 As shown, a flexible U-turn device for small packs of cigarettes includes a speed control unit, a sub-package unit and a reversing unit.

[0037] The speed control unit includes two sets of relatively rotating flat conveyor belts 1 arranged up and down, and the clamping space formed between the two sets of flat conveyor belts is the cigarette packet conveying channel 11. The two sets of flat conveyor belts are driven by the same servo motor 2.

[0038] The subpackaging unit includes two sets of relatively rotating belt rake conveyor belts 3, the two sets of belt rake conveyor belts 3 are arranged left and right, the space between the two sets of belt rake conveyor belts 3 is the cigarette packet subpackaging conveying channel 12, and the two sets of belt Rakes 4 are evenly distributed on the rake convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com