Valve port device with sealing function for valve bag

A valve pocket and valve port technology, which is applied in the field of valve pocket valve port devices, can solve the problems of reducing the valve port sealing effectiveness, tearing, and valve port glue falling off, so as to reduce leakage and pollute the environment, reduce losses, and prevent moisture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

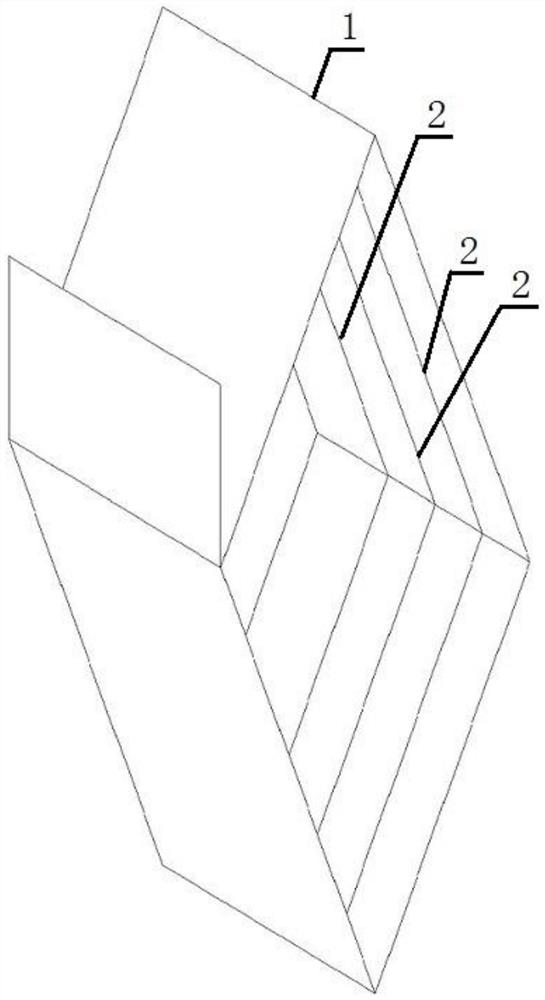

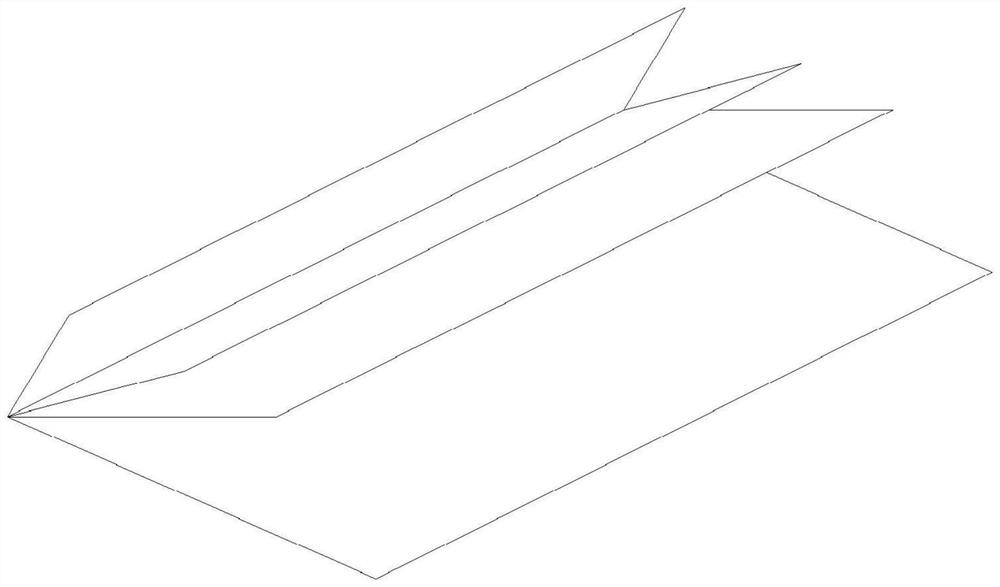

[0029] Such as Figure 1 to Figure 8 As shown, a valve pocket valve port device with a sealing function, hereinafter referred to as the valve port device. More than one valve plate 2 is arranged in the valve cylinder 1, and the end of the valve plate 2 facing the inlet of the valve cylinder is fixed on the inner wall of the valve cylinder, and the end of the valve disk 2 facing the outlet is movably separated from the valve cylinder.

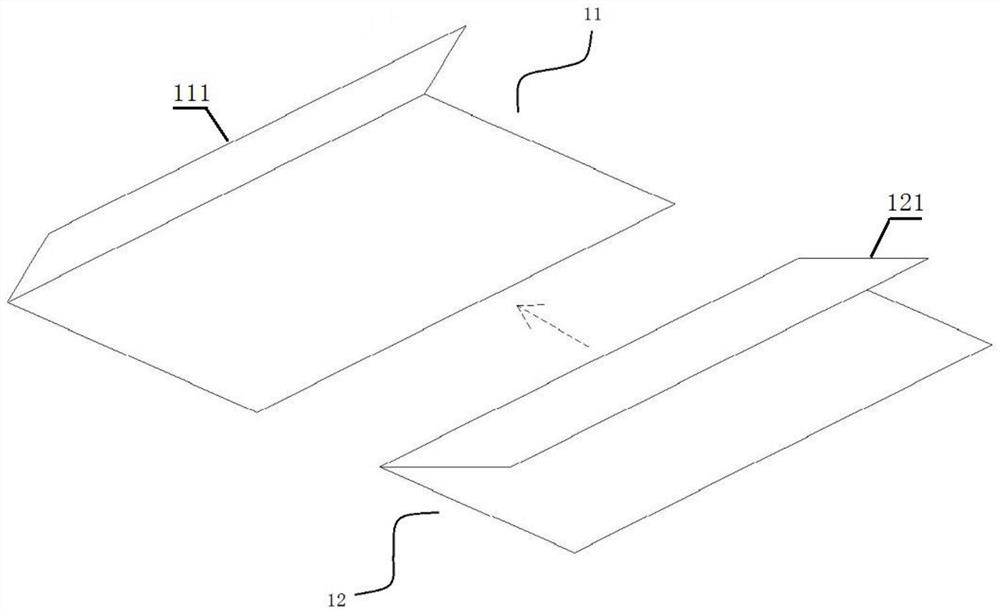

[0030] The valve barrel 1 includes a main valve 11, and the main valve also includes a main valve plate 111 folded from the inlet to the outlet.

[0031] For example, a valve plate 2 whose length is longer than that of the main valve plate can be directly inserted into the folding seam of the folded main valve and fixed, thereby forming a two-stage valve plate from the direction from the inlet to the outlet of the valve barrel.

[0032] The valve barrel also includes more than one secondary valves 12 nested in each other, and each secondary val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com