Detachable movable end wall

A movable end and detachable technology, which is applied in the field of detachable movable end walls, can solve problems such as inability to load goods, and achieve the effects of improving loading safety, low manufacturing cost, and strengthening connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

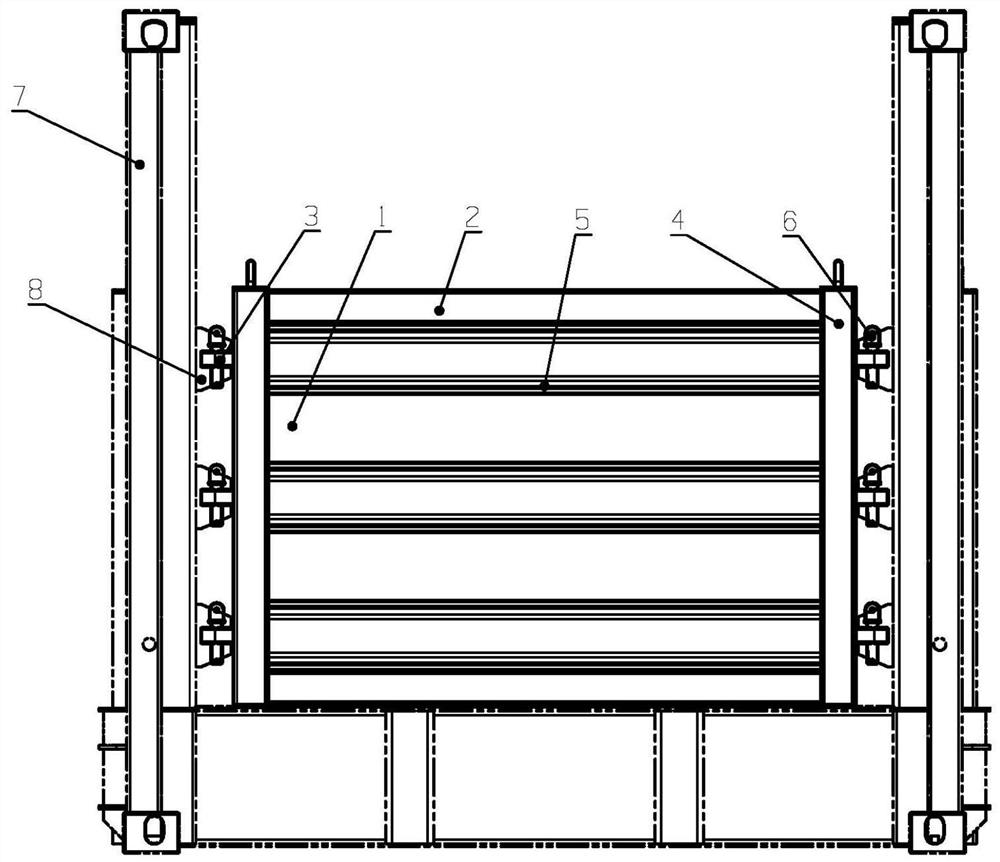

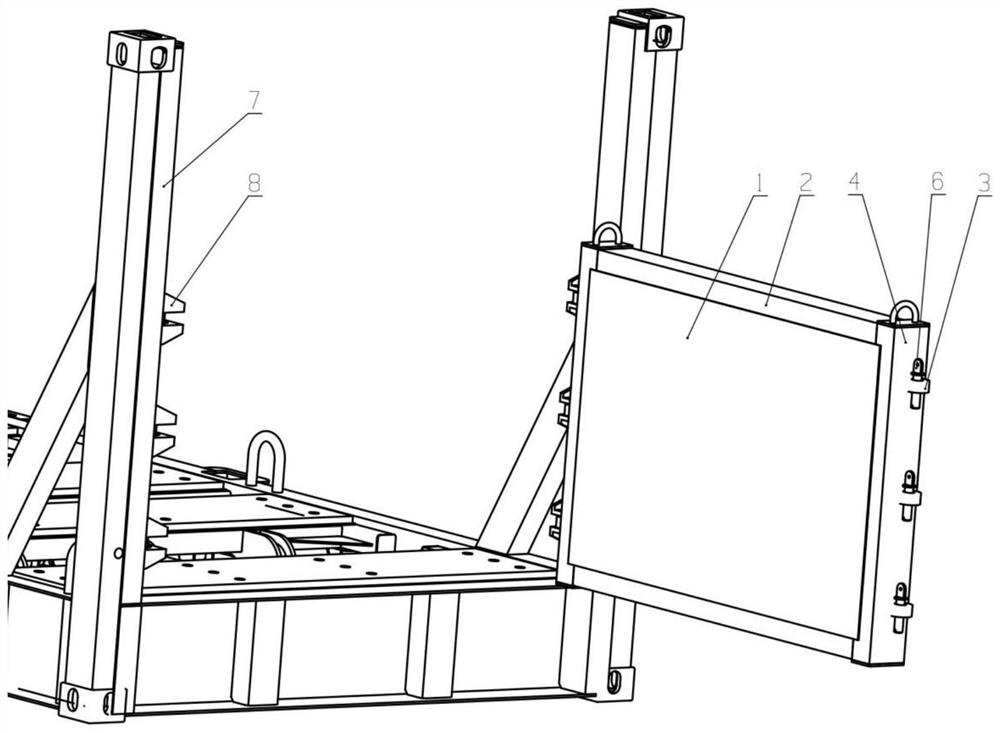

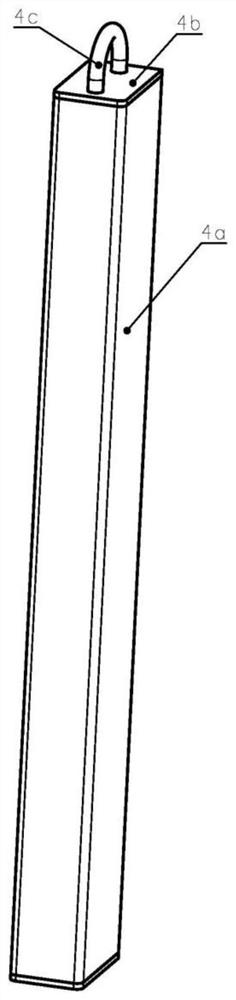

[0034] This embodiment is basically as figure 1 and figure 2 As shown: this embodiment provides a detachable movable end wall, which includes an end plate 1, an end beam 2, an end column composition 4 and a latch. The end plate 1 in this embodiment is rectangular and is located at the end of the pallet 7 part, and on the pallet 7 corresponding to both sides of the end plate 1, there are several latch seats 8; the end column composition 4 is fixed on both sides of the end plate 1, and the end column composition 4 is connected with the pallet 7 through the bolt composition The pin seat 8 on the top realizes detachable connection, and the end beam 2 is fixed on the upper and lower ends of the end plate 1, so that the end beam 2 and the end column form 4 around the end plate 1 to form a zigzag frame structure.

[0035] In this embodiment, the detachable movable end wall also includes a horizontal belt composition 5, which is fixed in the square frame structure and rigidly connec...

Embodiment 2

[0042] Embodiment 2 is basically the same as Embodiment 1, and the difference is that: as a preferred solution of Embodiment 1, in combination with figure 1 and Figure 4As shown, the present embodiment is provided with a horizontal band composition 5 rigidly connected to the end plate 1 in the square frame structure, so that the door bolt 3 passes through the end column composition 4 and the horizontal band composition 5 and is rigidly connected. The purpose of the design of the cross-belt composition 5 in the embodiment is not only to strengthen the structural strength of the end plate 1, but also to further strengthen the connection stability between the door bolt 3 and the end post composition 4. This design is ingenious and reasonable.

[0043] Specifically, the horizontal belt composition 5 includes a horizontal belt 5a corresponding to the door bolt 3 and a partition built into the inner side of the horizontal belt 5a. The partition board is provided with a mounting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com