Joint connecting structure of prefabricated floor slab and construction method

A technology of node connection and construction method, applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of collapse, mutual dislocation of connecting structures, endangering people's lives and property safety, etc., to prevent mutual dislocation, integrity and safety. The effect of continuity assurance, high stability and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

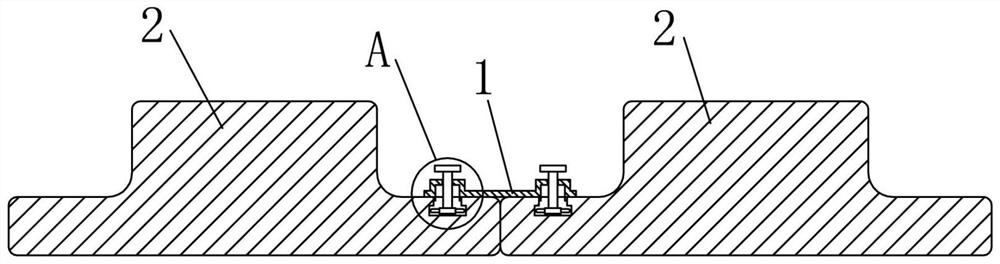

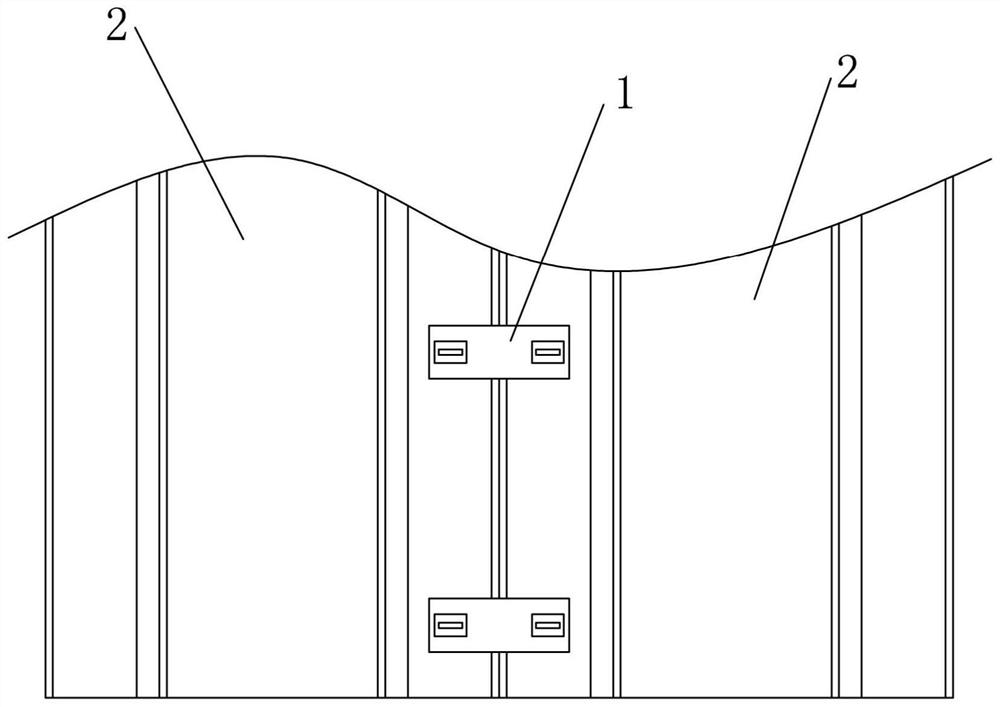

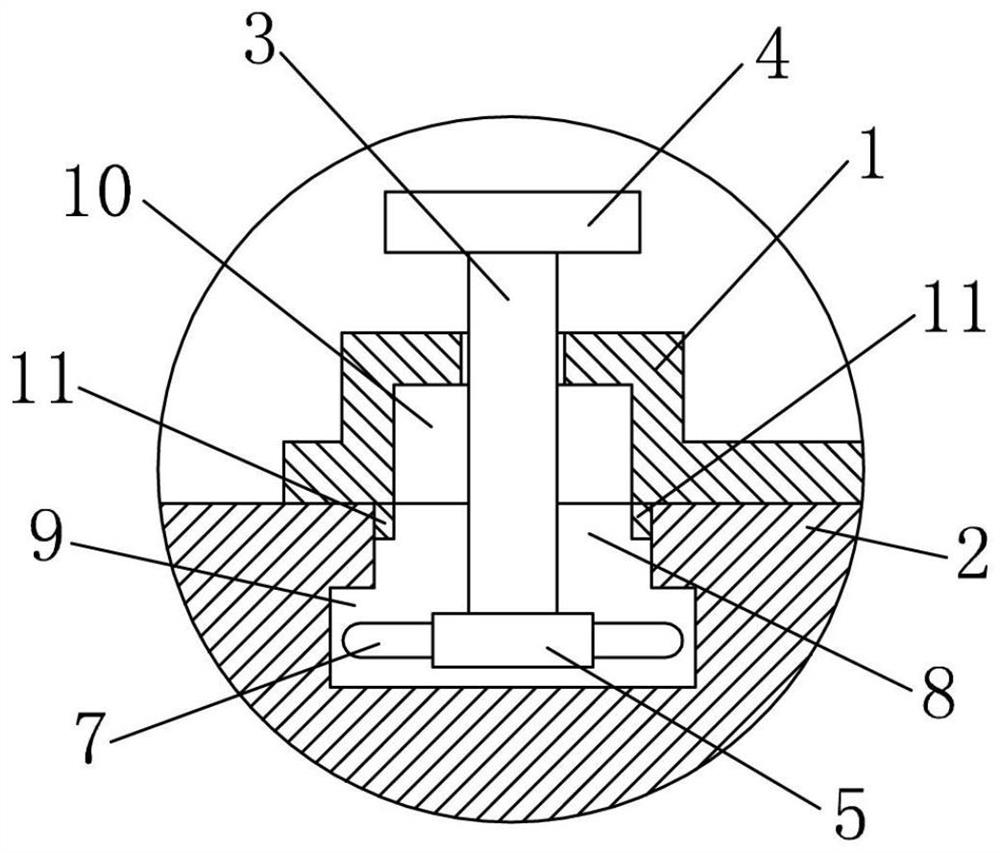

[0029]Example: A node connection structure for prefabricated floor slabs, such asFigure 1-Figure 8As shown, it includes a fixing board 1, which is placed at the junction of two adjacent prefabricated floor slabs 2. Both sides of the fixing board 1 are provided with connecting components, and the prefabricated floor slab 2 is clamped by the connecting components. Two adjacent prefabricated floor slabs 2 are connected.

[0030]The connecting assembly includes a vertical rod 3, a handle 4, and a clamping module. The handle 4 is fixedly arranged at the top end of the vertical rod 3. The bottom end of the vertical rod 3 penetrates the fixing plate 1 and is connected to the clamping module. The vertical rod 3 is movably connected to the fixed board 1 up and down, the prefabricated floor slab 2 is provided with a card slot matching the card connection module, and the card connection module is engaged with the card slot.

[0031]The clamping module includes a clamping socket 5, the clamping socke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com