Connection structure of flexibly-packaged high-capacity battery cell and pole

A battery cell and connection structure technology, which is applied in the field of connection structure between soft-packed high-capacity battery cells and poles, can solve the problems of increasing the internal resistance of the tabs, affecting the overcurrent capability of the tabs of the cell, etc. The effect of large connection area, prevention of virtual welding, and increase of overcurrent area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

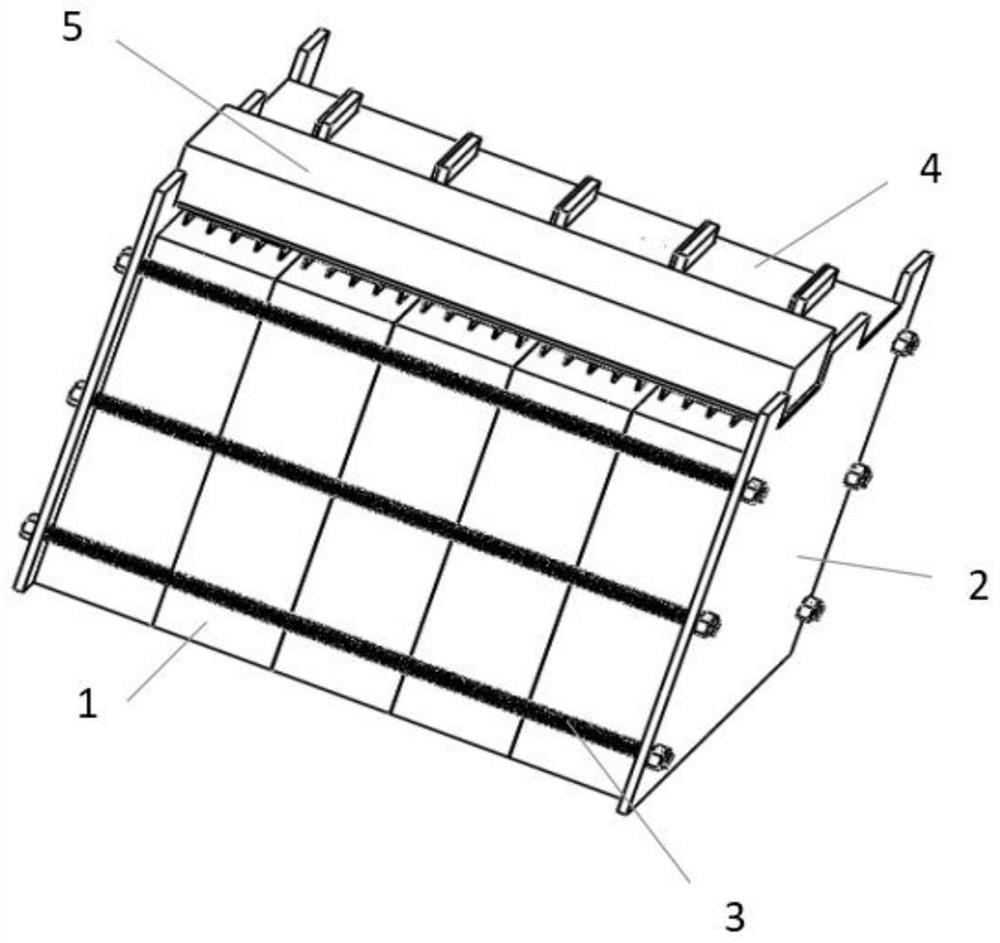

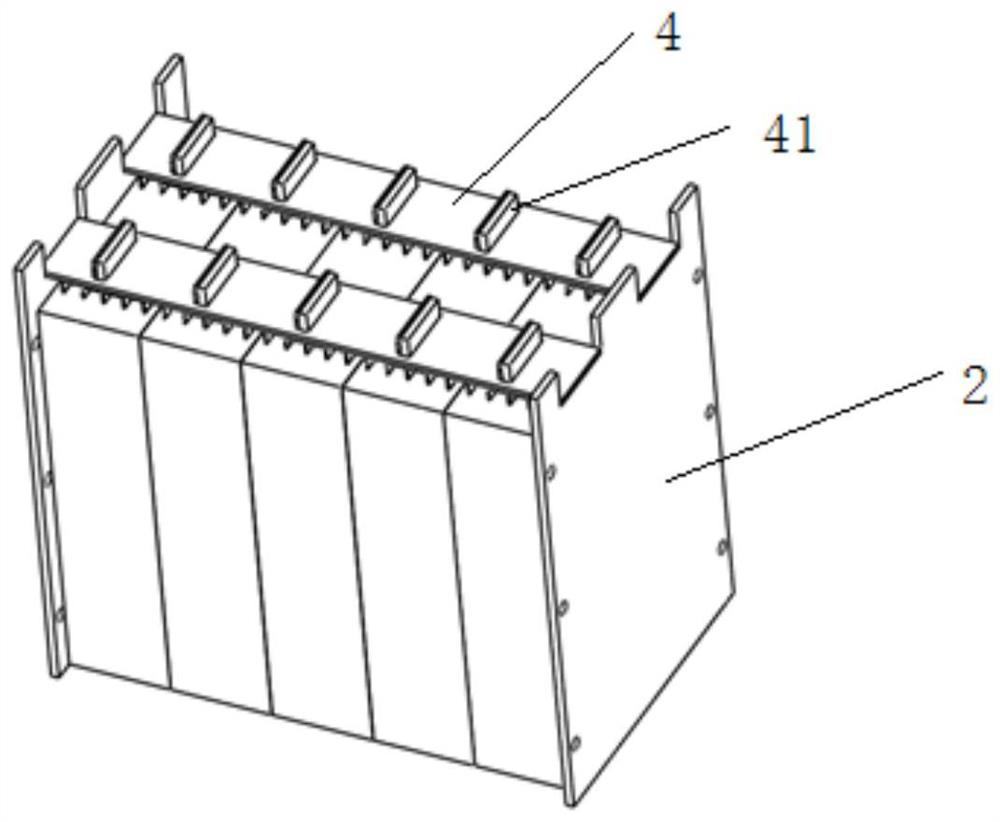

[0043] see Figure 1-Figure 2 , the present embodiment is a connection structure between a soft-packed large-capacity battery cell and a pole, which includes a soft-packed cell 1 and a bus bar 4, and the bus bar 4 is divided into a positive bus bar and a negative bus bar. Through holes 42 are provided on the negative busbars, and connecting plates 41 are arranged at the throughholes 42. The busbars 4 are plate-shaped structures with a rectangular cross section. The ear 6 is divided into a positive pole lug and a negative pole lug. The positive pole lug runs through the through hole on the positive pole bus and fits the connection plate 41 on the positive pole bus. The negative pole lug runs through the through hole on the negative pole bus and the connection plate on the negative pole 41 fit.

[0044] Preferably, the through holes 42 in this embodiment are arranged along the width direction of the bus bar 4 .

[0045] Preferably, the connecting plate 41 of this embodiment is a...

Embodiment 2

[0047] This embodiment is a connection structure between a soft-packed large-capacity battery cell and a pole. On the basis of Embodiment 1, there are 50 soft-packed cells 1, and the 50 soft-packed cells 1 are arranged side by side in two rows. , 25 in each row, and each row is correspondingly provided with a positive electrode bus bar and a negative electrode bus bar.

[0048] The positive tabs on the pouch cell 1 are connected in one-to-one correspondence with the through holes 42 on the corresponding positive busbar; the negative tabs on the pouch cell 1 are connected in one-to-one correspondence with the through holes 42 on the negative busbar.

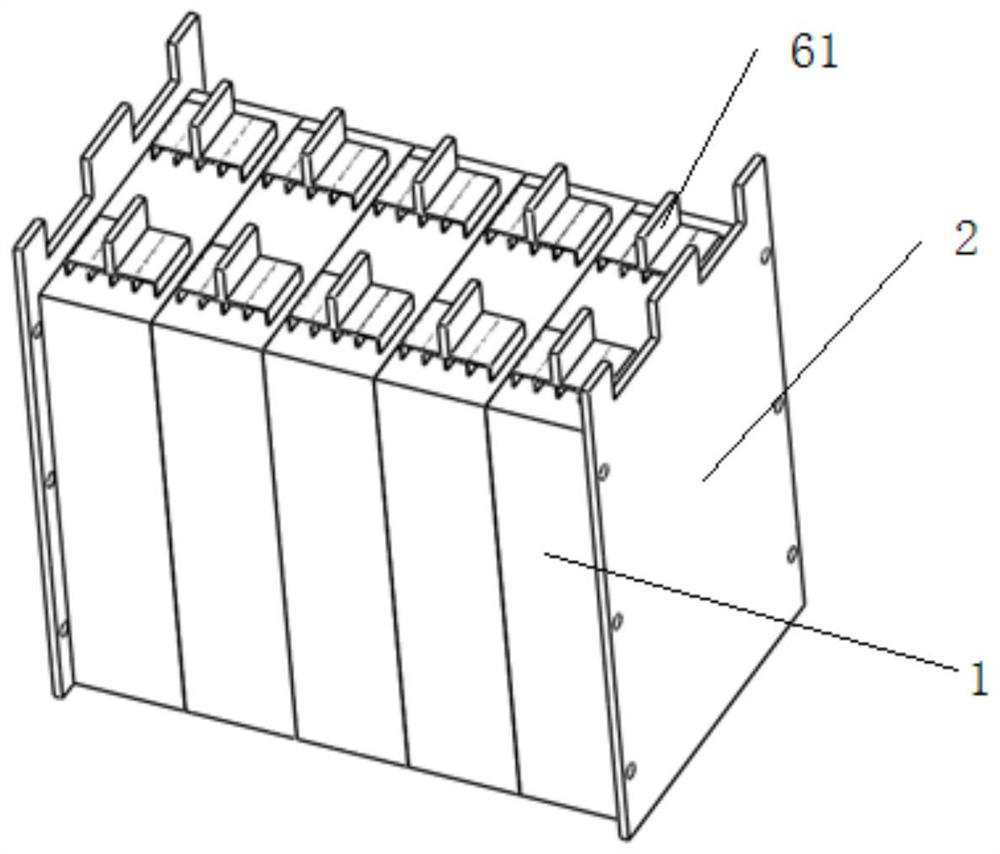

[0049] see image 3 , or 5 pouch cells 1 in each row as a group, a tab bundle 61 formed by connecting positive tabs on 5 pouch cells 1 in the same group, and 5 pouch cells in the same group The negative tabs on 1 are connected to form a tab bundle 61, that is, the positive tabs and negative tabs formed in each row form five tab b...

Embodiment 3

[0057] This embodiment is a connection structure between a soft-packed large-capacity battery cell and a pole. On the basis of Example 2, 30 soft-packed cells 1 are stacked side by side to form a battery module. The splint 2 clamps and fixes 30 padded cells 1 through the fixed splint 2; the fixed splint 2 and the padded cell 1 are arranged side by side.

[0058] Preferably, in this embodiment, six screw rods 3 are arranged between the two fixing splints 2 , and the six screw rods 3 are in two groups respectively, and are respectively arranged on opposite sides of the battery module.

[0059] The fixing splint 2 in this embodiment can be one of PP board, PE board, PVC board, PET board, PPS board, PPA board, PEEK board or LCP board; it can play the role of insulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com