Material formula and production process of automatic winding packaging film

A production process and automatic technology, which is applied in the field of agricultural harvesting crop packaging materials, can solve the problems of complex structure of separable adhesive tapes, large demand for adhesives, complicated production processes, etc., and achieves remarkable packaging effect and saves adhesives. The amount of use and the effect of good puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

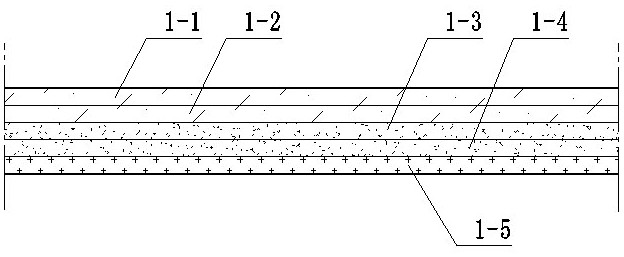

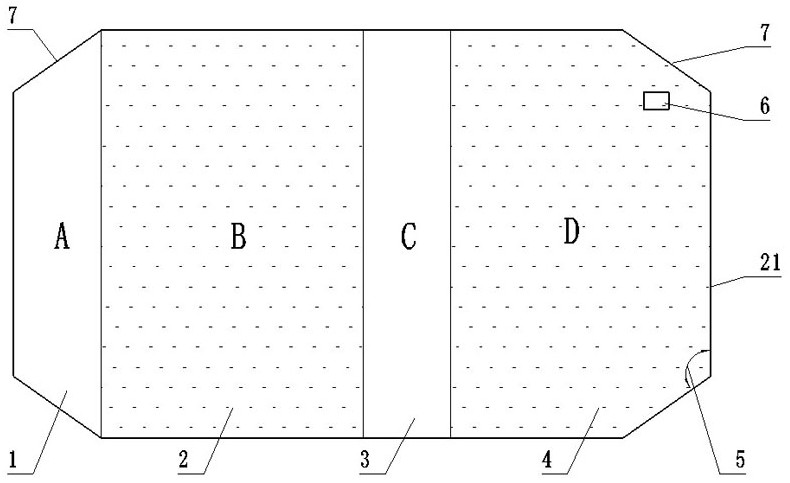

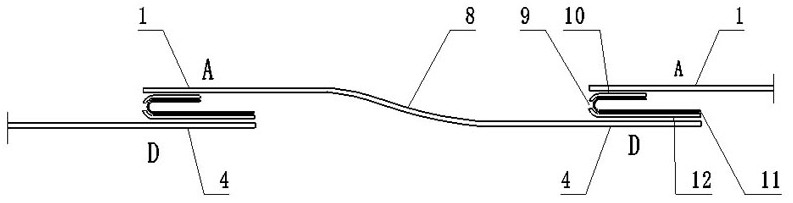

[0070] Refer to the attached figure 1 , a material formula for winding automatic packaging film, measured by mass percentage, mainly including the following raw materials: linear low density polyethylene, high pressure low density polyethylene, metallocene polyethylene, color masterbatch, anti-aging agent, ultraviolet absorber, anti-aging agent electrostatic agent;

[0071] The anti-aging agent is: antioxidant 1010, namely tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester;

[0072] The ultraviolet absorber is: 2-hydroxy-4-n-octyloxybenzophenone;

[0073] The antistatic agent is: octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate;

[0074] Stir the above-mentioned raw materials uniformly according to the following formula ratio, and use the five-layer co-extrusion film blowing machine equipment to carry out blow molding:

[0075] The raw material ratio of inner layer 1 and inner layer 2 is as follows: high pressure low density pol...

Embodiment 2

[0079] A material formula for winding automatic packaging film, measured by mass percentage, mainly includes the following raw materials: linear low density polyethylene, high pressure low density polyethylene, metallocene polyethylene, color masterbatch, anti-aging agent, ultraviolet absorber, antistatic agent;

[0080] The anti-aging agent is: anti-oxidant 1076, namely β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate;

[0081] Described ultraviolet absorber is: 2-(2'-hydroxyl-3',5'-di-tert-butylphenyl)-5-chlorobenzotriazole;

[0082] The antistatic agent is: octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate;

[0083] Stir the above-mentioned raw materials uniformly according to the following formula ratio, and use the five-layer co-extrusion film blowing machine equipment to carry out blow molding:

[0084]The raw material ratio of inner layer 1 and inner layer 2 is as follows: high pressure low density polyethylene 12%, linear low density polyethylene ...

Embodiment 3

[0088] A material formula for winding automatic packaging film, measured by mass percentage, mainly includes the following raw materials: linear low density polyethylene, high pressure low density polyethylene, metallocene polyethylene, color masterbatch, anti-aging agent, ultraviolet absorber, antistatic agent;

[0089] The anti-aging agent is: antioxidant 1010, namely tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester;

[0090] The ultraviolet absorber is: 2-hydroxy-4-n-octyloxybenzophenone;

[0091] The antistatic agent is: octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate;

[0092] Stir the above-mentioned raw materials uniformly according to the following formula ratio, and use the five-layer co-extrusion film blowing machine equipment to carry out blow molding:

[0093] The raw material ratio of inner layer 1 and inner layer 2 is as follows: high pressure low density polyethylene 14%, linear low density polyethylene 45%, met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com