Multistage centrifugal supercritical carbon dioxide compressor

A carbon dioxide and supercritical technology, applied in mechanical equipment, non-displacement pumps, non-displacement pumps, etc., can solve problems such as low aerodynamic efficiency, large leakage flow at the shaft end, and poor system stability, so as to improve stability and Reliability, reduction of axial thrust, and improvement of compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

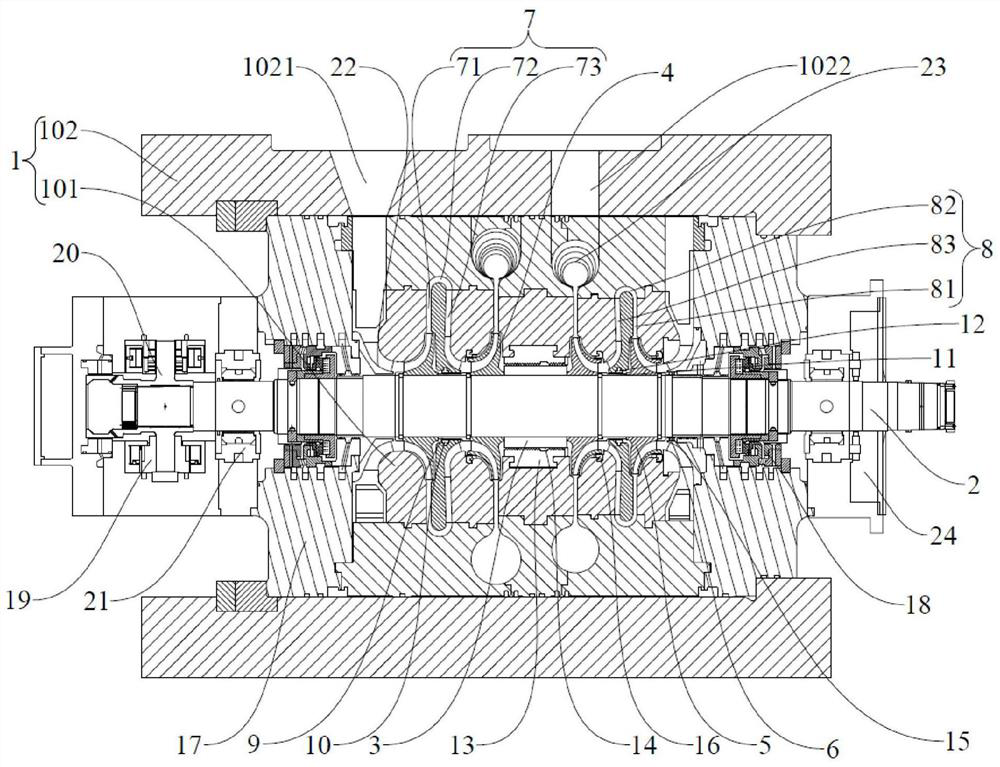

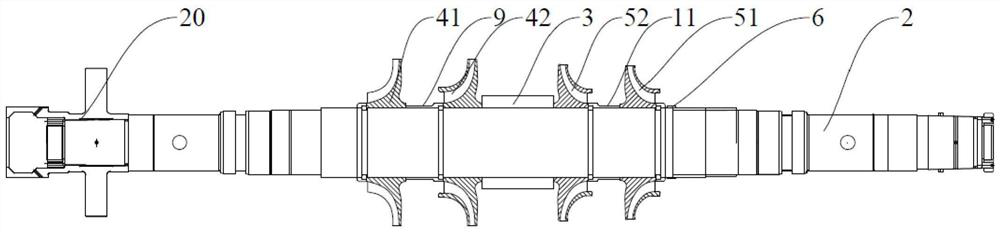

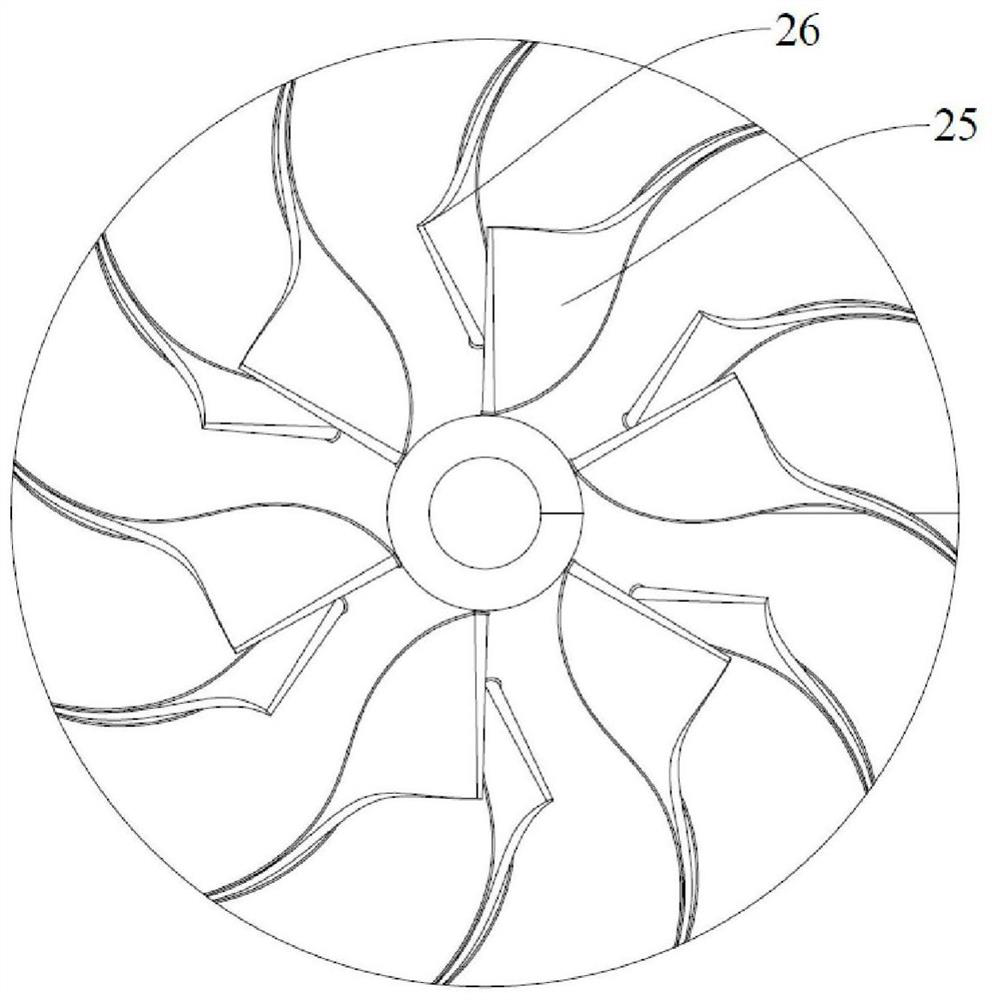

[0054] Refer below Figure 1-Figure 3 Describe the structure of a multi-stage centrifugal supercritical carbon dioxide compressor in a specific embodiment of the present invention.

[0055] Such as Figure 1-Figure 3As shown, the multistage centrifugal supercritical carbon dioxide compressor of this embodiment includes a casing 1, a main shaft 2, an interaxial balance disc 3, a low-pressure stage impeller 4, a high-pressure stage impeller 5, a shaft end balance disc 6, and a first return flow assembly 7 and the second backflow assembly 8, the first spacer 9, the first interstage seal 10, the second spacer 11, the second interstage seal 12, the end cap 17 and the dry gas seal 18.

[0056] The casing 1 is a cylindrical cylinder structure. The casing 1 includes an inner cylinder 101 and an outer cylinder 102 sleeved on the inner cylinder 101 . The outer cylinder 102 is provided with an inlet pipe 1021 and an outlet pipe 1022 . The inner cylinder 101 is provided with an inlet gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com