Pilot valve for pilot type safety valve and pilot type safety valve

A technology of pilot-operated safety valves and pilot-operated valves, which is applied to safety valves, valve operation/release devices, valve details, etc., can solve the problems of decreased sensitivity and precision, reduced valve performance, and high pressure-sensing precision, so as to improve control and Driving ability, improving forward sealing and reverse sealing ability, ensuring the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

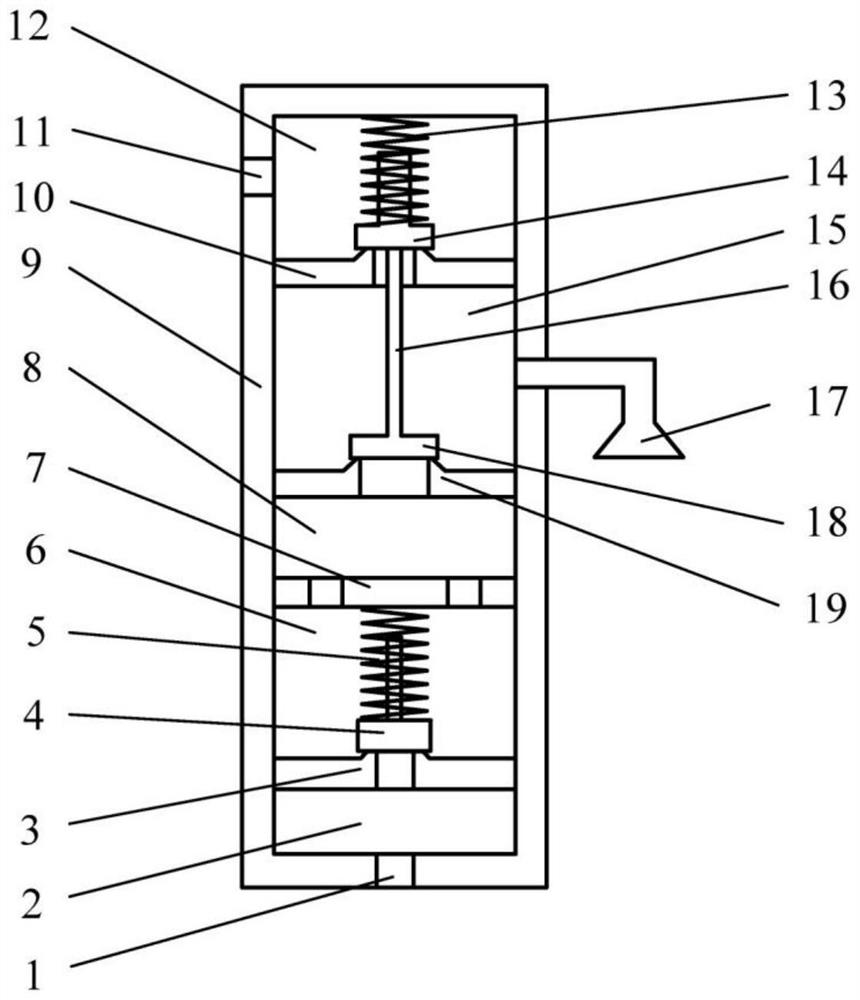

[0038] A pilot valve for a pilot-operated safety valve, including a drive valve 39, a balance valve 55 and an auxiliary valve 56, the pilot valve outlet 17 is arranged on the balance valve 55; the drive valve seat 10 of the drive valve 39 has a flow path The area is less than or equal to the flow path area of the balance valve seat 19 of the balance valve 55; the auxiliary valve inlet 1 of the auxiliary valve 56 is used to connect the main valve inlet 36 of the main valve 37 of the pilot safety valve, and the outlet of the auxiliary valve 56 It is connected to the inlet of the balance valve 55; the balance disc 18 of the balance valve 55 is pressed against the balance valve seat 19 by the secondary side pressure passing through the outlet 17 of the pilot valve in state 1, and the balance valve 55 is driven by medium pressure in state 2 The balance valve rod 16 pushes back the driving disc 14 of the driving valve 39 .

[0039] Wherein, the balance valve 55 is divided into a b...

Embodiment 2

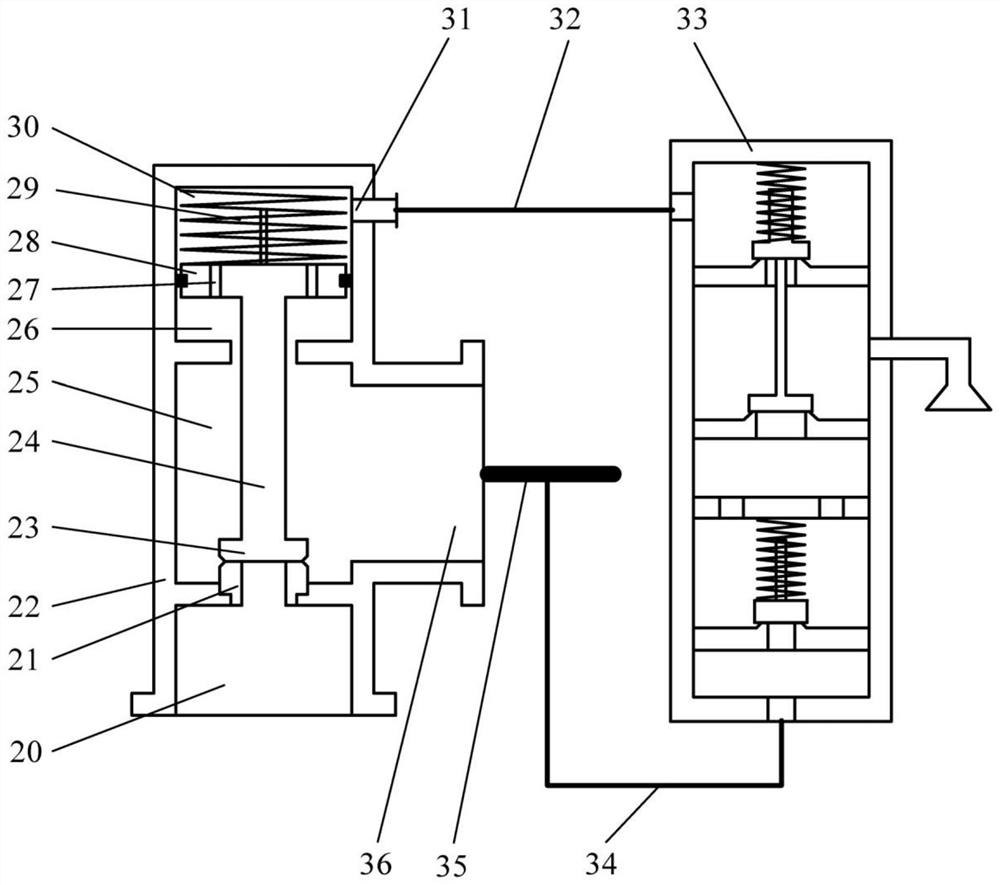

[0053] Based on Embodiment 1, the difference is that the auxiliary valve 56 is divided into an auxiliary valve chamber 6 and an auxiliary valve discharge chamber 8 by the auxiliary valve seat 3; Tighten the spring 40, the auxiliary valve discharge chamber 8 is connected to the outlet of the drive valve 39; the balance valve 55 includes a pressure sensing chamber 47, and the pressure sensing chamber 47 is provided with a pressure sensing bellows 46; the pressure sensing chamber 47 is provided with a pressure-sensing chamber inlet 48, and the pressure-sensing chamber inlet 48 is used to connect the main valve inlet 36 of the main valve 37 of the pilot safety valve; the auxiliary valve 56 is provided with an auxiliary valve opening push rod 42, and the One end of the auxiliary valve opening ejector rod 42 is connected with the pressure-sensitive bellows 46 to drive the auxiliary valve opening ejector rod 42 to push the auxiliary valve disc 4 through the contraction of the pressure...

Embodiment 3

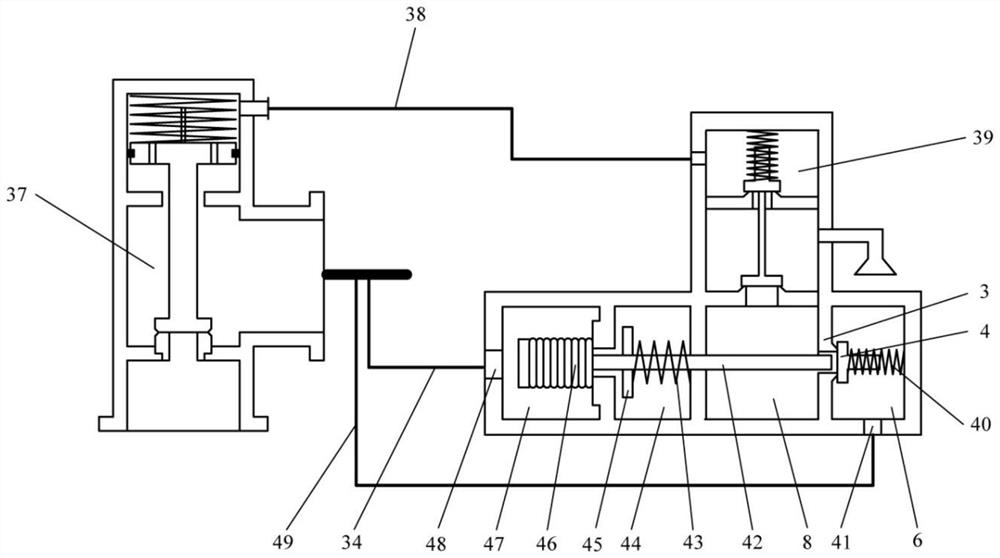

[0060] Based on Embodiment 1, the difference is that it also includes a secondary drive valve 60; the secondary drive valve 60 is divided into a secondary drive valve piston upper cavity 52 and a secondary drive valve piston lower cavity 57 by a secondary drive valve piston 51 The secondary drive valve piston 51 is provided with a secondary drive valve back pressure hole 54; the secondary drive valve piston upper cavity 52 is provided with a secondary drive valve reset preload spring 53, and the secondary drive valve piston lower The chamber 57 is divided into an inlet and an outlet of the secondary driving valve 60; the inlet of the driving valve 39 communicates with the piston upper chamber 52 of the secondary driving valve

[0061] Such as Figure 4 As shown, it can be understood that the driving valve function module of the pilot valve is a two-stage driving valve module, through the flow amplification effect of the secondary driving valve 60 on the driving valve 39, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com