Induction heating assembly of floor heating heater

An induction heating and heater technology, applied in water heaters, fluid heaters, heating methods, etc., can solve the problem of uneven heating of water flow, achieve the effect of uniform heating of water flow and improve heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

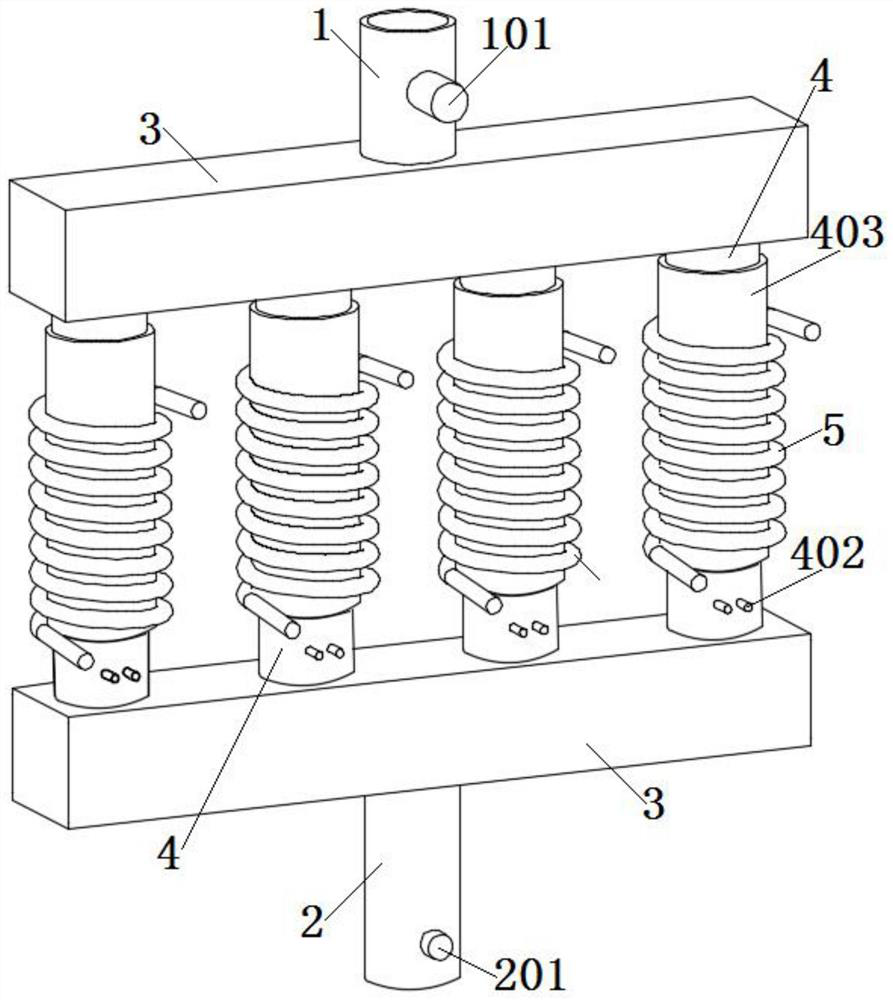

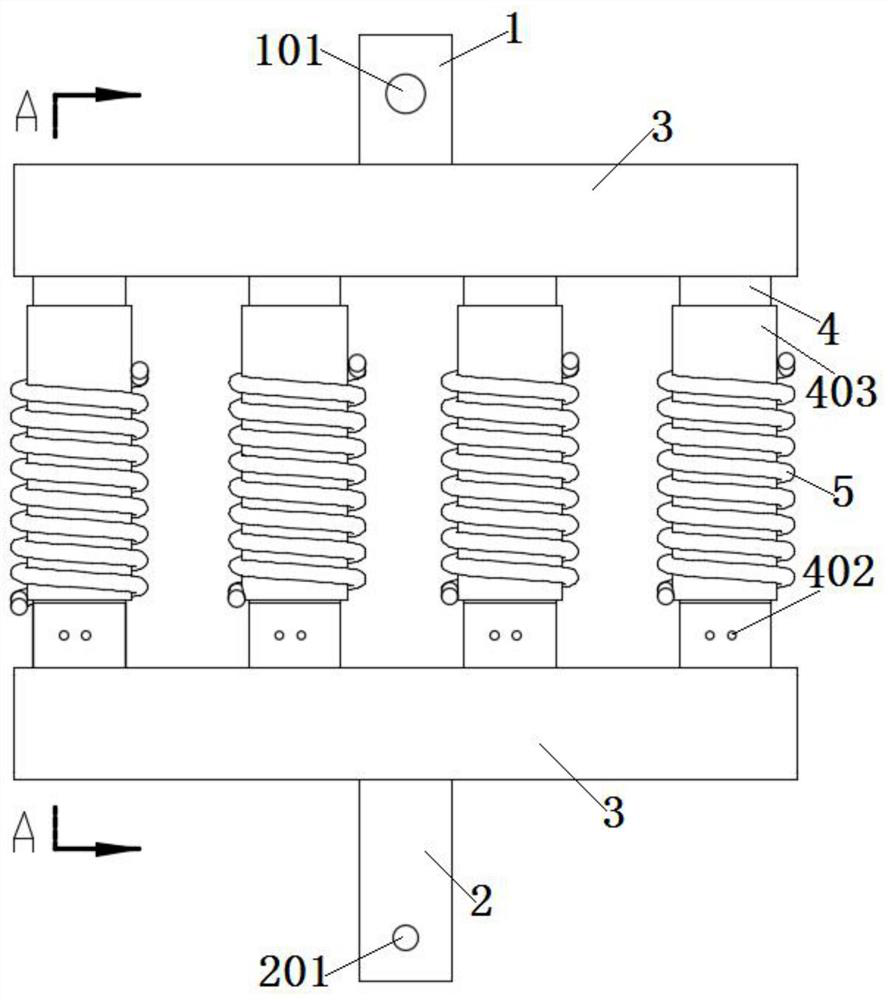

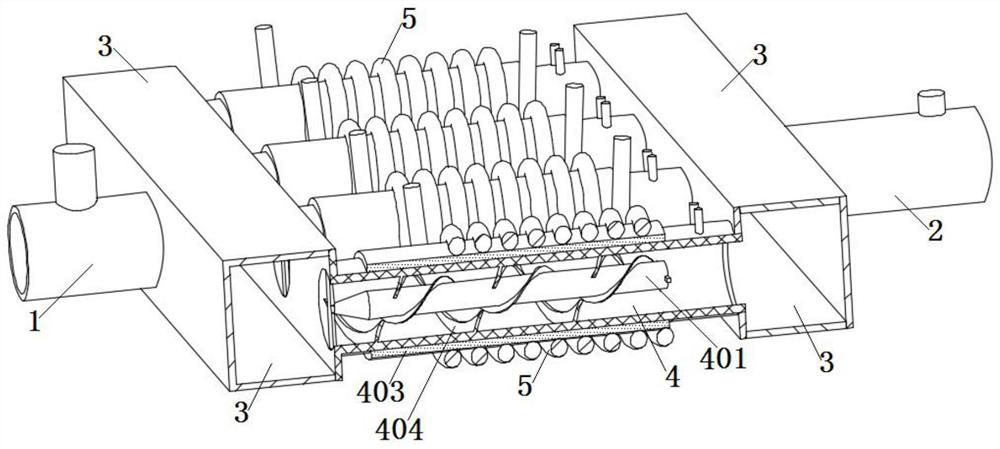

[0034]Seefigure 1 with2As shown, the present invention is an induction heating component of a floor heating heater, including a water inlet pipe 1 and a water outlet pipe 2; both the water inlet pipe 1 and the water outlet pipe 2 are connected with rectangular pipes 3 with closed ends; the water inlet pipe 1 is connected with a water flow sensor Switch 101; the outlet pipe 2 is connected with a first temperature sensor 201.

[0035]Four heating tubes 4 are connected in parallel between the two rectangular tubes 3, and the water inlet tube 1, the water outlet tube 2, the rectangular tube 3 and the heating tube 4 are all connected to each other. Both ends of the heating tube 4 are connected to the rectangular tube 3 through flanges, so that the heating tube 4 is easy to disassemble and install. The heating tube 4 can also be directly connected to the rectangular tube 3 by welding.

[0036]The heating tube 4 is sleeved with an electromagnetic induction coil 5; the electromagnetic induction c...

Embodiment 2

[0044]Such asfigure 1 with2As shown, both the water inlet pipe 1 and the water outlet pipe 2 are connected with a rectangular pipe 3 with closed ends. The water inlet pipe 1 and the water outlet pipe 2 and the rectangular pipe 3 can be connected by flange connection or direct welding connection. The water inlet pipe 1 is connected with a water flow sensor switch 101; the water outlet pipe 2 is connected with a first temperature sensor 201.

[0045]Four heating tubes 4 are connected in parallel between the two rectangular tubes 3, and the water inlet tube 1, the water outlet tube 2, the rectangular tube 3 and the heating tube 4 are all connected to each other. Both ends of the heating tube 4 are connected to the rectangular tube 3 through flanges, so that the heating tube 4 is easy to disassemble and install.

[0046]The heating tube 4 is sleeved with an electromagnetic induction coil 5; the electromagnetic induction coil 5 is connected with the control circuit. The inner wall of the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com