A compound falling film evaporator and refrigeration device

A falling film evaporator and composite technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of affecting commercial competition, increasing the manufacturing cost of heat exchangers, and unfavorable miniaturization of evaporators. Achieving effects that are conducive to miniaturization, performance improvement, and cooling capacity loss avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the examples.

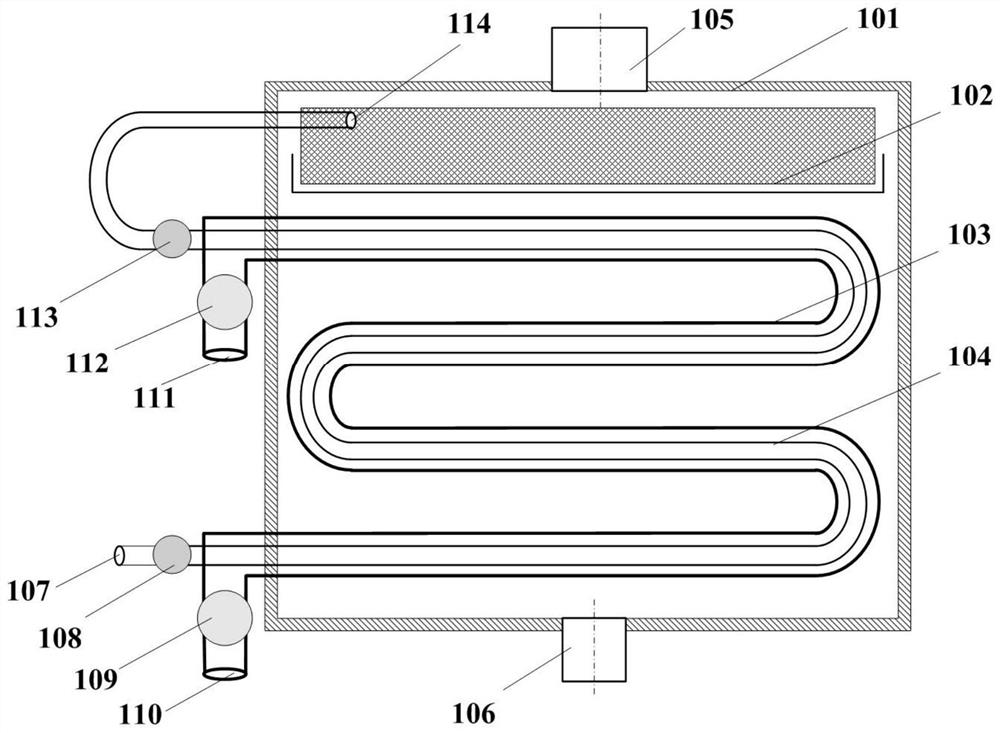

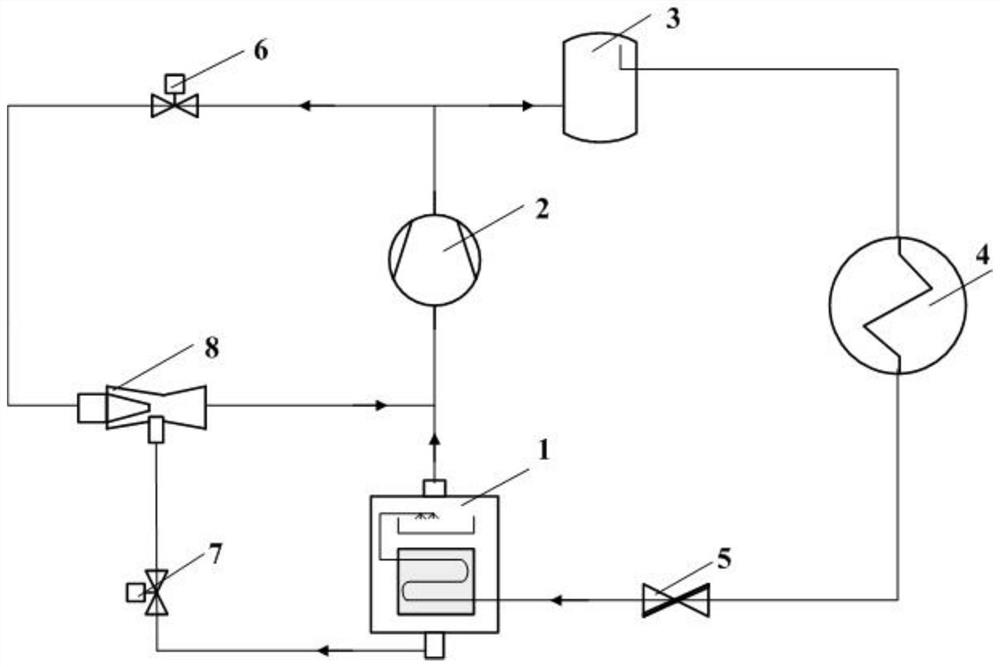

[0021] Such as figure 1 As shown, a compound falling film evaporator of this embodiment mainly includes: casing module, liquid distributor 102, chilled water inlet 111, chilled water outlet 110, refrigerant inlet 107, refrigerant outlet 114, lubricating oil collection bag 106 , gas outlet 105 and housing 101 , etc., the gas outlet 105 is located at the top of the housing 101 , and the lubricating oil collection bag 106 is located at the bottom of the housing 101 .

[0022] The liquid distributor 102 is located in the upper area of the housing 101, and the bushing module is located in the lower area of the housing 101, consisting of a bushing array and several connecting pipes; the bushing array is formed by a plurality of bushings, and a single bushing It consists of an outer tube 103 and an inner tube 104 nested together. The entrance of the outer pipe 103 in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com