Evaporative cooler with fog eliminating function

An evaporative cooling and functional technology, applied in the direction of evaporator/condenser, water shower cooler, direct contact heat exchanger, etc. Large water evaporation loss and other problems, to achieve the effect of reducing evaporation loss, reducing spray water, and saving water energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings. Those skilled in the art should understand that the following does not constitute a limitation to the protection scope of the present invention.

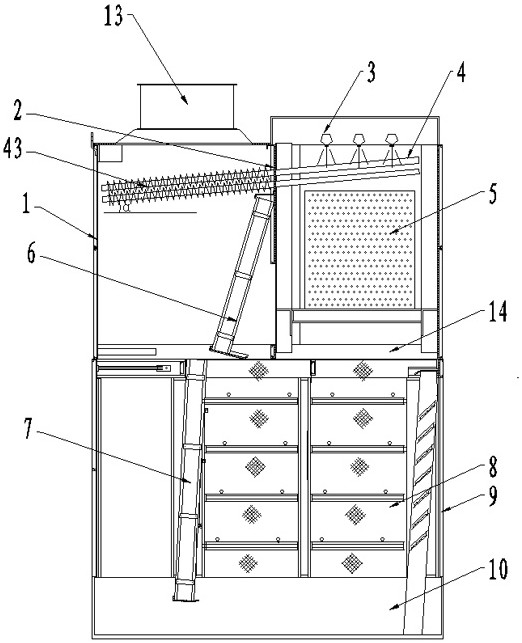

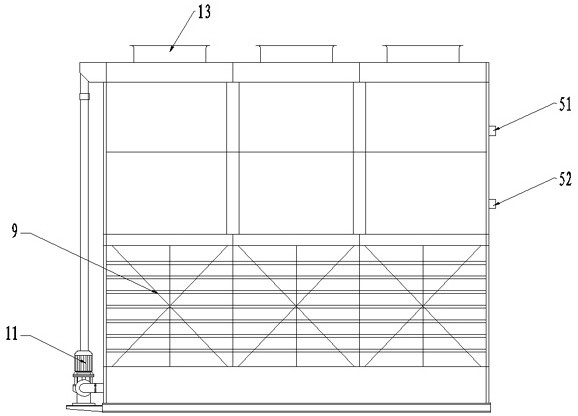

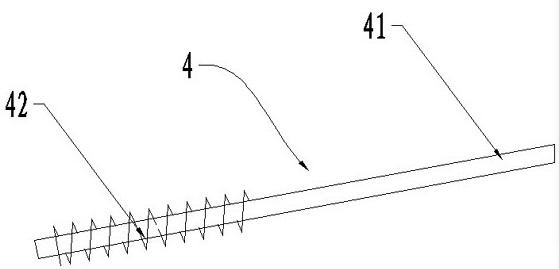

[0035] Examples such as Figure 1-3 As shown, an evaporative cooler with the function of defogging includes a casing 1 , and a blower 13 is arranged on the top of the casing 1 , and the air inside the casing 1 is discharged through the blower 13 .

[0036] In order to strengthen the heat transfer outside the tube, the blower 13 can be designed as a single unit or as a combination of multiple units.

[0037] The lower part of the housing 1 is provided with louvers 9, and the louvers 9 are fresh air inlets;

[0038] The air duct 13 and the louvers 9 are arranged on both sides of the casing 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com