Low-energy-consumption counterflow closed cooling tower

A closed cooling tower, low energy consumption technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc. Adverse effects and other problems, to achieve the effect of facilitating maintenance operations, reducing height, and eliminating white fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

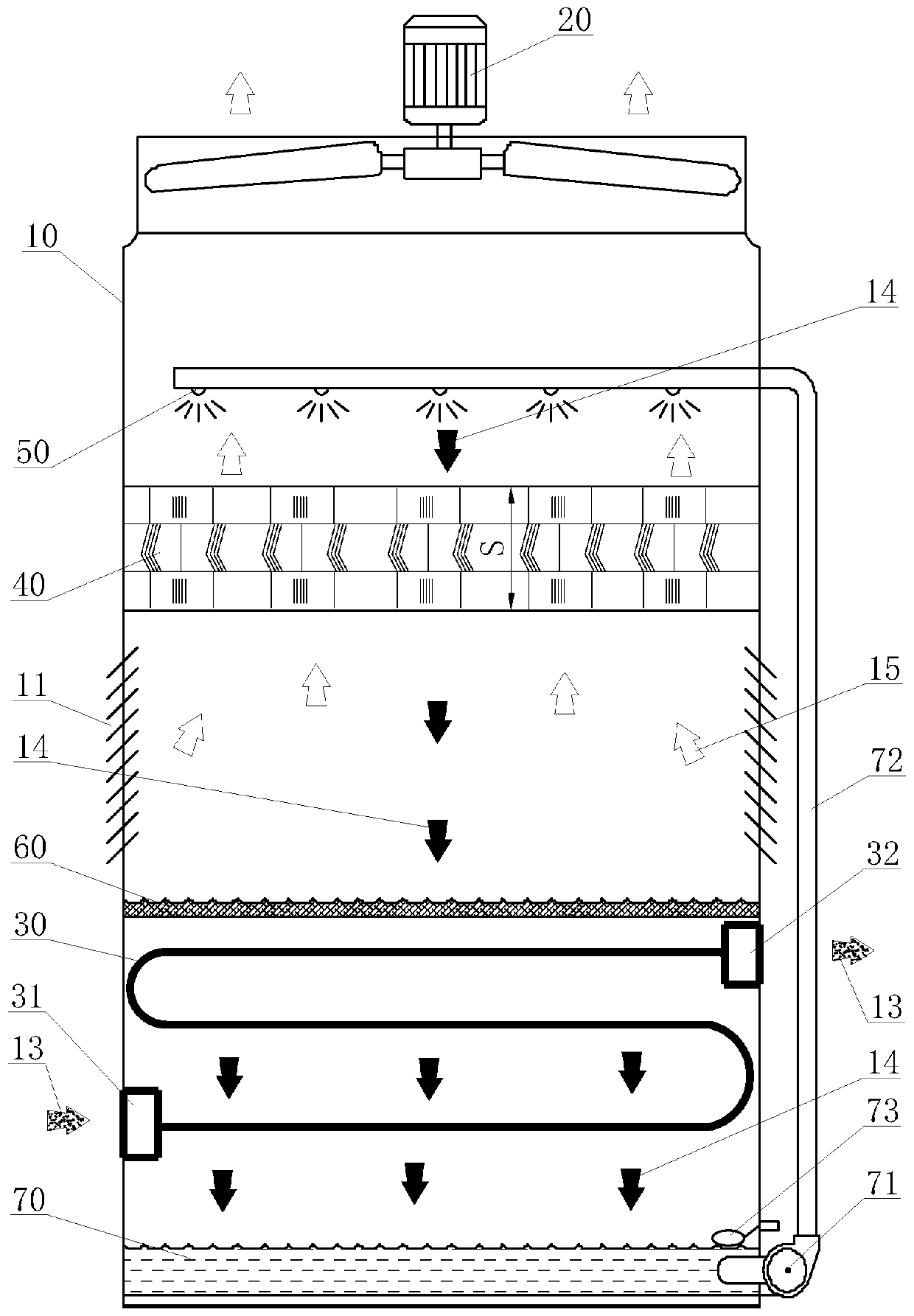

[0027] Such as figure 1 , a low energy consumption counter-flow closed cooling tower, comprising a cooling tower shell 10 and a fan 20 installed on the top of the cooling tower shell.

[0028] The bottom of the cooling tower housing is provided with a circulating water tank 70 for collecting and storing cooling water, and the circulating water tank is provided with a float valve 73 for replenishing water.

[0029] A water-cooled heat exchange tube bundle 30 is arranged in the cooling tower shell and above the circulating water tank. The cooled medium 13 flows in the water-cooled heat exchange tube bundle. The water-cooled heat exchange tube bundle is provided with an input interface 31 and an output interface 32 . The structure of the water-cooled heat exchange tube bundle can adopt the coil type, the straight tube box type, and the plate tube type. This embodiment adopts coil type.

[0030] A water distribution pan 60 is arranged above the water-cooled heat exchange tube ...

Embodiment 2

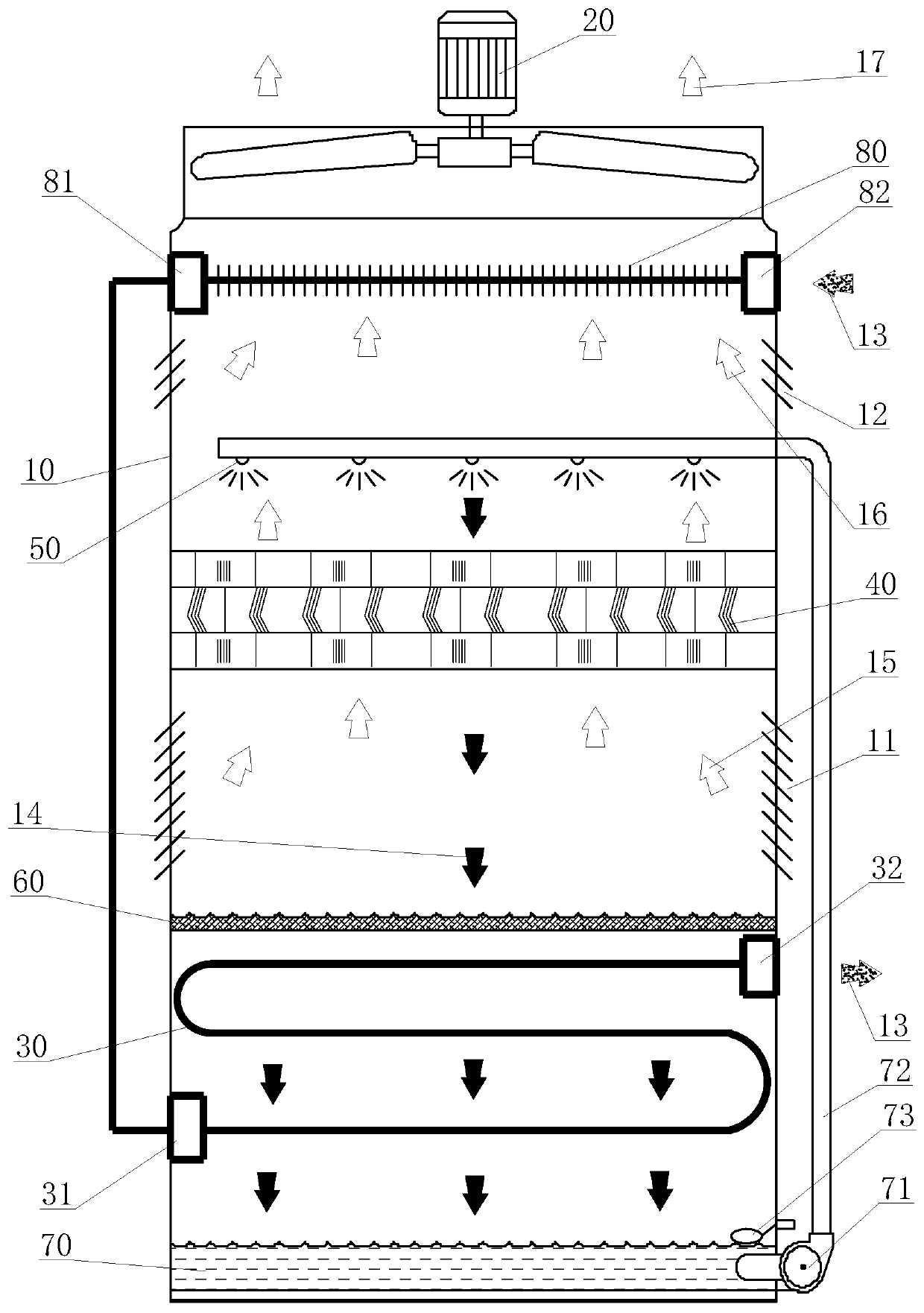

[0041] Such as figure 2 , a low energy consumption counter-flow closed cooling tower, this embodiment is an improvement of the first embodiment.

[0042] In this embodiment, an air-cooled heat exchange tube bundle 80 is provided above the shower head 50 . The cooling tower shell between the spray head and the air-cooled heat exchange tube bundle is provided with a second air inlet window 12 . The structure of the air-cooled heat exchange tube bundle can adopt rolled finned tube heat exchange tubes, wound finned heat exchange tubes, aluminum alloy flat tube brazed fin heat exchange tubes, aluminum tubes through aluminum fin heat exchange tubes, this embodiment Aluminum alloy flat tubes are used to braze finned heat exchange tubes.

[0043] The air-cooled heat exchange tube bundle is provided with an output interface 81 and an input interface 82, and the output interface 81 of the air-cooled heat exchange tube bundle is connected to the input interface 31 of the water-cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com