Blast furnace flushing slag flue gas whitening integrated device

A blast furnace slag flushing and flue gas technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as white plume, and achieve the effects of flexible land occupation, important application value, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

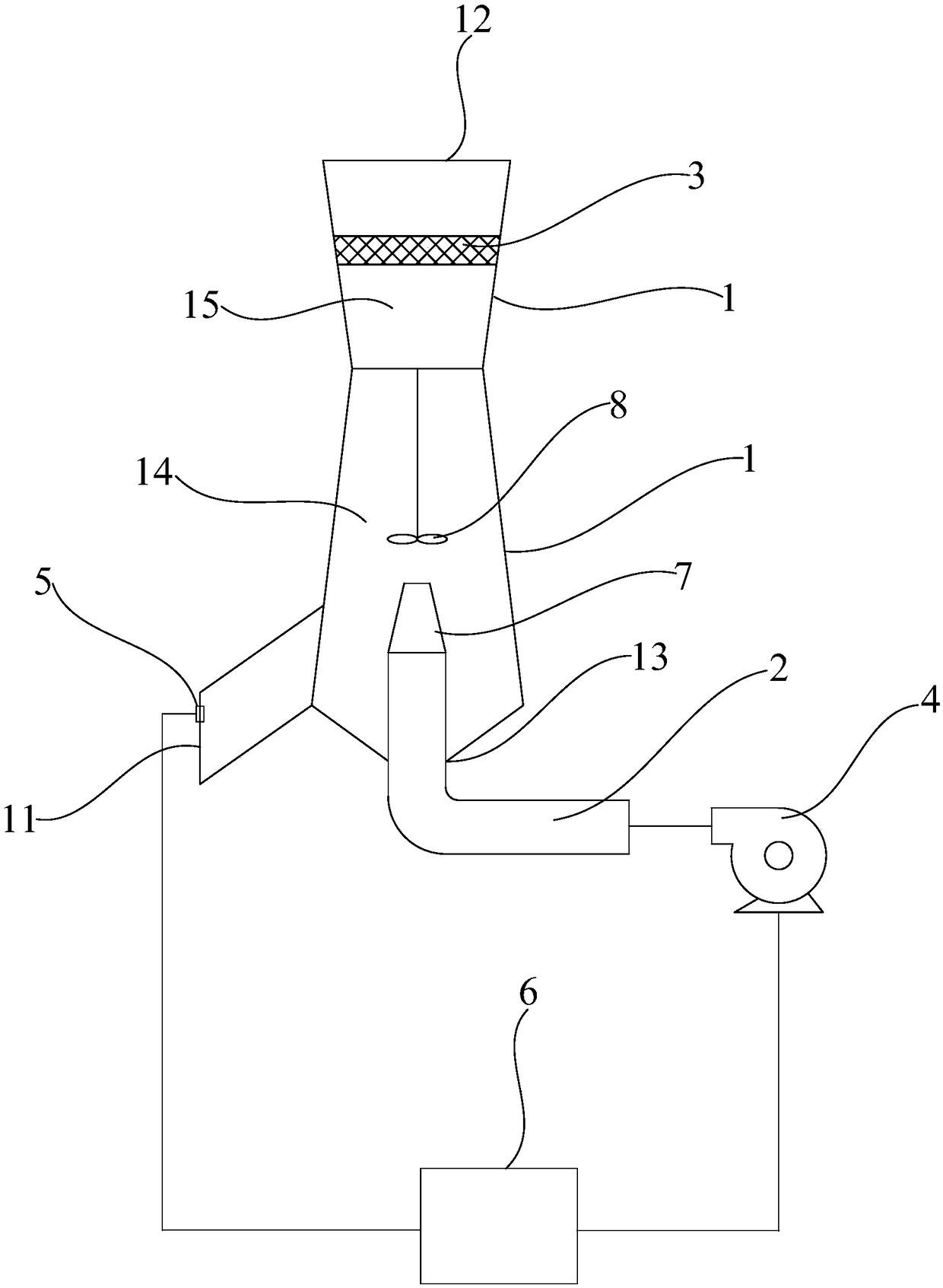

[0035] like figure 1 As shown, this embodiment discloses a blast furnace slag flushing flue gas whitening integrated device, the blast furnace slag flushing flue gas whitening integrated device includes a shell 1 and a hot air pipe 2, and the shell 1 includes a mixing zone 14 , the housing 1 is provided with a flue gas inlet 11, a flue gas outlet 12 and a hot blast inlet 13, the flue gas outlet 12 is located above the mixing zone 14, the flue gas inlet 11 and the hot blast inlet 13 are located at the bottom of the mixing zone 14, and the hot blast duct 2 Connected to the hot air inlet 13 and communicated with the mixing zone 14. The blast furnace slag flushing flue gas enters the mixing area 14 of the shell 1 through the flue gas inlet 11, and the external hot air is transported to the hot air inlet 13 through the hot air pipe 2, and then enters the mixing area 14 of the shell 1 through the hot air inlet 13. The blast furnace slag flushing flue gas will be mixed with the exte...

Embodiment 2

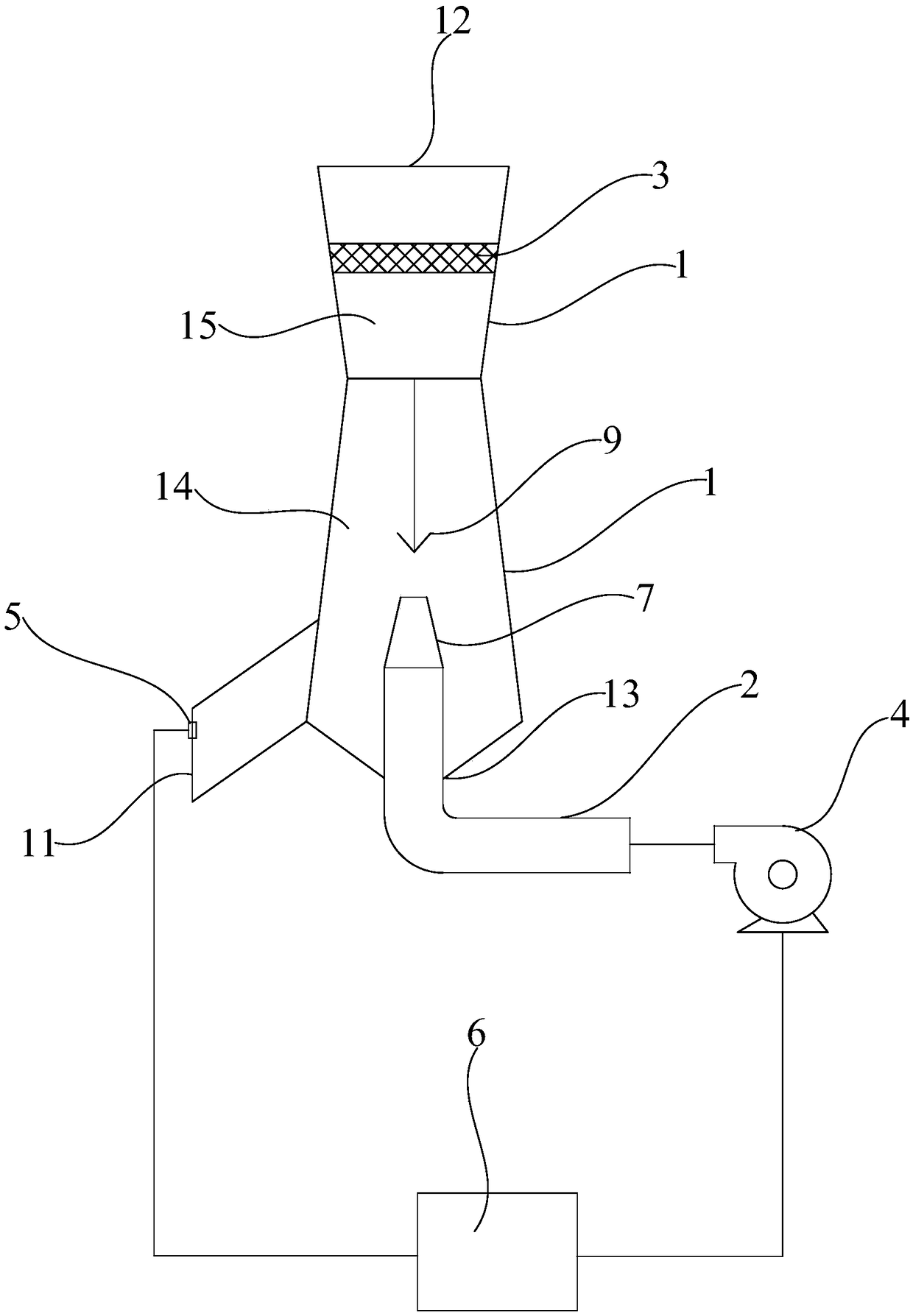

[0054] The difference between this embodiment and Embodiment 1 is that the blast furnace slag flushing and flue gas whitening integrated device of this embodiment does not include a dust collector 3, and the blast furnace slag flushing flue gas whitening integrated device of this embodiment includes Lifting air cap 9, rising air cap 9 is located in mixing zone 14, and rising air cap 9 is positioned at the top of hot air inlet 13. The hot blast enters into the mixing zone 14 through the hot blast inlet 13 and the nozzle 7, the tip of the air lift cap 9 faces down and is positioned directly above the nozzle 7, the hot blast will flow to the air lift cap 9 and spread out, and the entrainment in the hot air Moisture will be blocked on the gas-lifting cap 9, which improves the whitening effect of the blast furnace slag flushing flue gas whitening integrated device. At the same time, the furnace slag flue gas and hot air will be diffused through the gas lift cap 9, so that the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com