Refrigerator

A refrigerator and fin technology, applied in the field of refrigerators, can solve the problems of affecting the heat exchange efficiency of the evaporator, requiring a long time for defrosting, and difficult installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

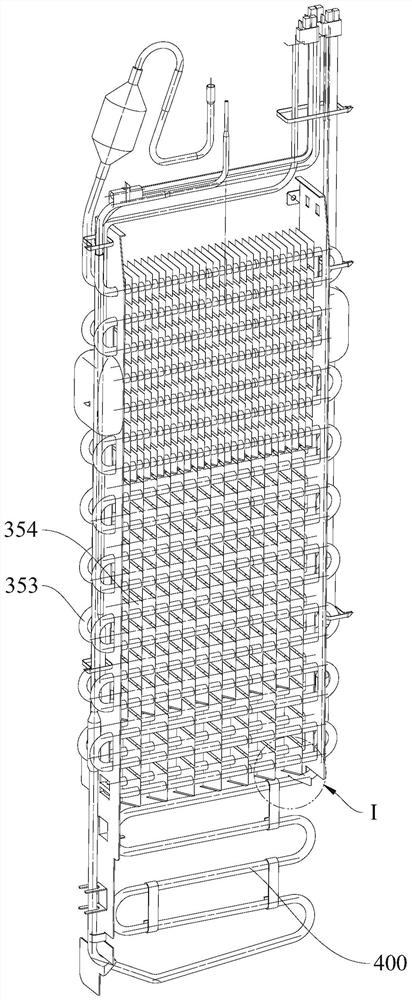

[0045] In this example, refer to Figure 1-Figure 7 , the bottom edge of the fin 354 is inclined perpendicular to the axis of the coil tube, that is, the bottom edge of the fin 354 is inclined forward and backward, one end is higher and the other end is lower. The bottom edge of the fin 354 is provided with a bent portion 3541, and the bent portion 3541 forms the water guiding portion. After the defrosting water flows down vertically along the fins 354 , guided by the bent portion 3541 , flows down along the bottom of the bent portion 3541 , and drips from one side of the fins 354 into the water receiving tank.

[0046] Furthermore, in order to allow the defrosting water to flow down smoothly and quickly and increase the water guiding effect of the bent portion 3541 , a hydrophobic layer (not shown) is also provided on the upper surface of the bent portion 3541 . Specifically, the surface of the bent portion 3541 is coated with a hydrophobic material, preferably a super-hydro...

Embodiment 2

[0053] The difference between the second embodiment and the first embodiment is that the structure of the water guiding part is different. like Figure 8 As shown, in this embodiment, the lower part of the fin 354 is provided with an inclined groove 3542 depressed along the surface of the fin 354, and the groove 3542 forms a water guide. The fins 354 are rectangular, and the lower part of the fins 354 is punched with an inclined groove 3542 through a stamping process. Both the inner concave surface and the outer convex surface of the groove 3542 form the water guiding part, and both have a flow guiding effect. A hydrophobic layer is provided on both the inner concave surface and the outer convex surface of the groove 3542 . The fins 354 are in the shape of a rectangle, which is convenient for arranging the fins during processing, and the groove 3542 is punched out through a stamping process, which is easy to operate. It should be pointed out that the structure of the water g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Width range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap