Gravity assisted heat pipe with multi-stage evaporation sections for refrigerating equipment with super-concentrated cooling capacity

A technology of gravity heat pipes and refrigeration equipment, which is applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of heat transfer efficiency decline, gravity heat pipe stop working, and reduce the driving force of liquid working medium flow in heat pipes, etc., to achieve Improve the effect of using the angle range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

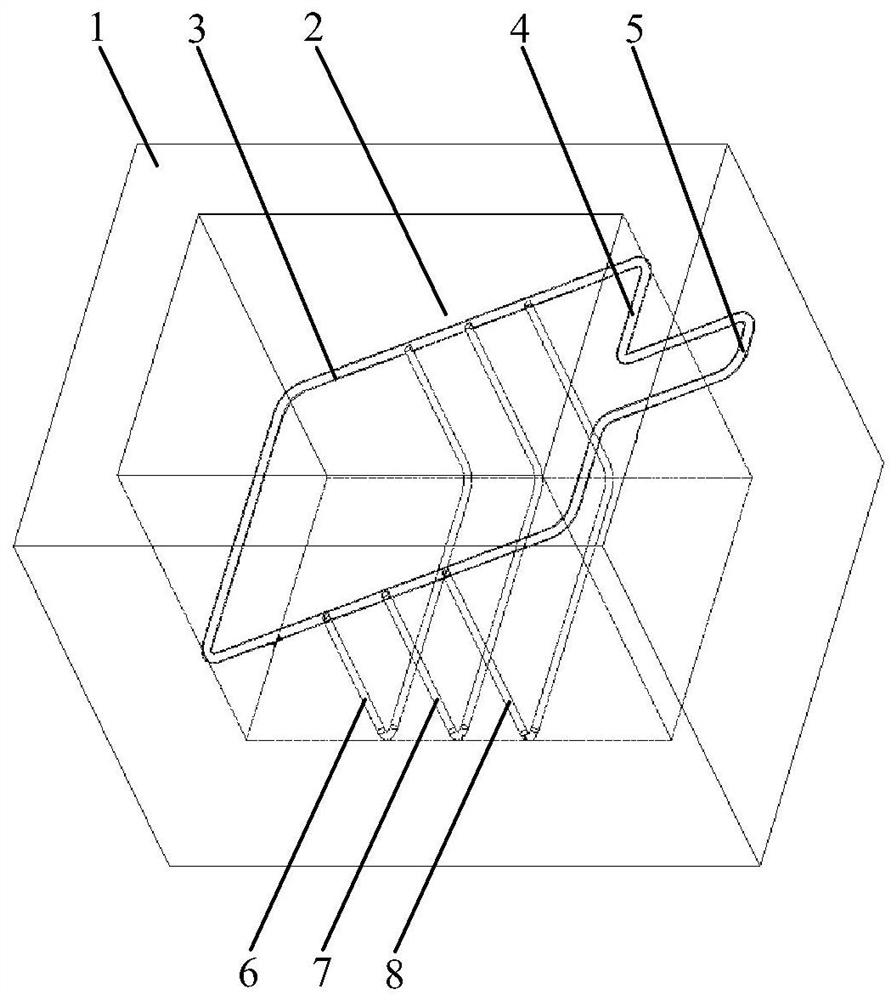

[0026] refer to Figure 1-3 , this embodiment provides a gravity heat pipe with multi-stage evaporating sections for super-centralized cooling equipment. The gravity heat pipe 2 is installed in a low-temperature storage box 1 with a Stirling refrigerator as a cold source. The preservation box 1 includes a box shell and an inner container arranged inside the box shell, and a heat insulating layer is arranged between the box shell and the inner container. In this embodiment, the ring-shaped gravity heat pipe 2 is arranged around the inner tank of the cryogenic storage box 1. The gravity heat pipe 2 includes the main evaporation section 3, the heat insulation section 4 and the condensation section 5, and the heat insulation section 4 is located between the main evaporation section 3 and the condensation section 5. Among them, the main evaporation section 3 is in contact with the inner tank of the low temperature storage box 1, the heat insulation section 4 is arranged in the heat...

Embodiment 2

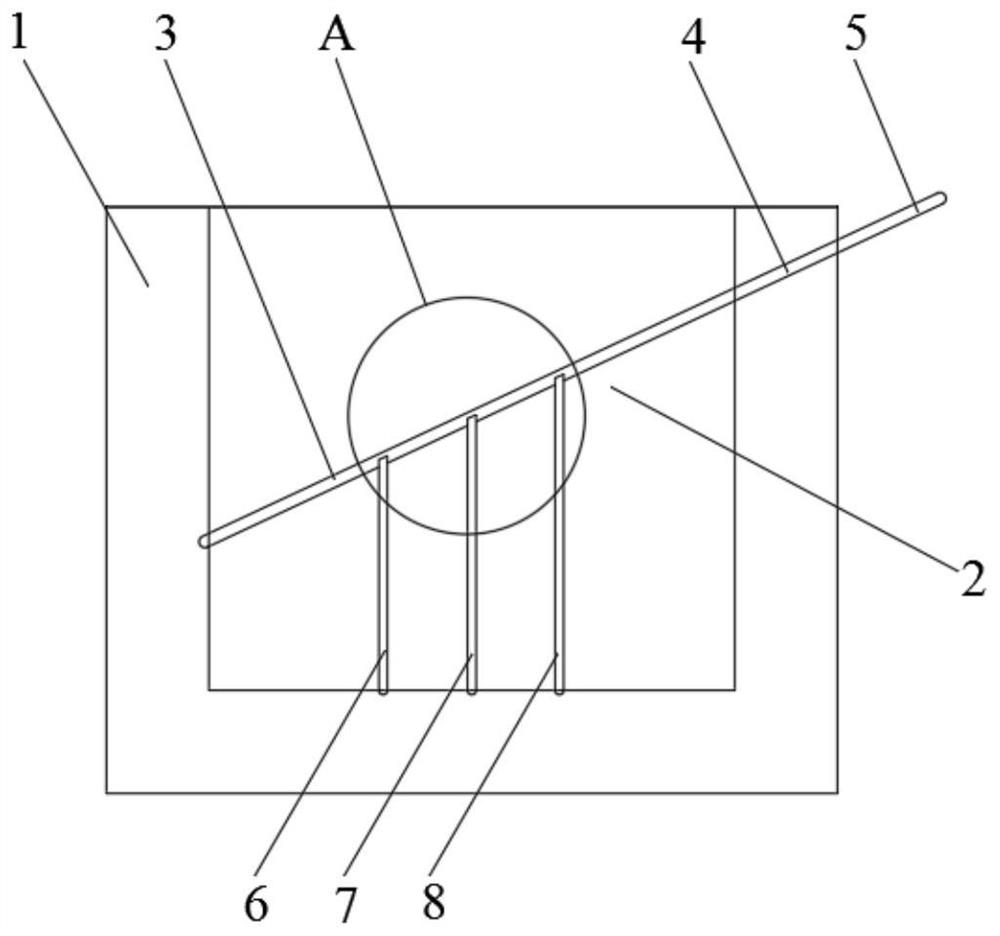

[0036] refer to Figure 4-6 , the main difference between this embodiment and Embodiment 1 is that: in this embodiment, the gravity heat pipe 2 adopts a ring-shaped gravity heat pipe 2, and the primary standby evaporation tube 6 and the secondary standby evaporation tube 7 are arranged below the main evaporation section 3 of the gravity heat pipe 2 , the primary standby evaporator tube 6 and the secondary standby evaporator tube 7 are arranged obliquely relative to the horizontal plane.

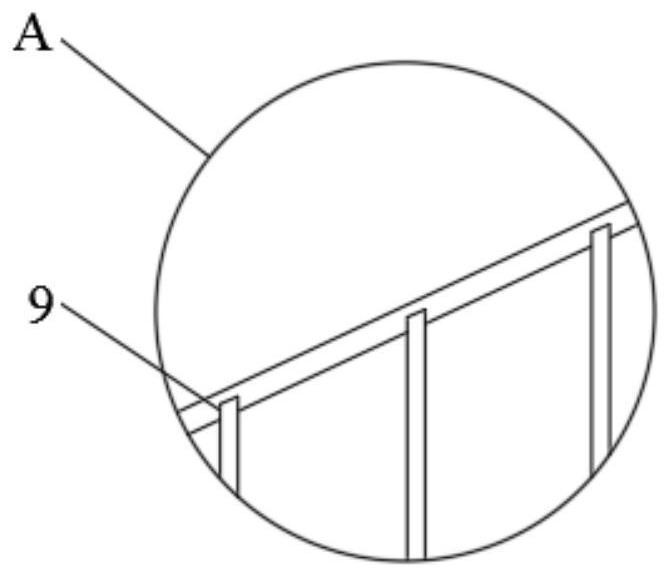

[0037] In this embodiment, the included angle between the gravity heat pipe 2 and the horizontal plane is 25°, the inclination angle of the top nozzle of the liquid blocking section 9 is 30°, and the included angle between the primary standby evaporator tube 6 and the secondary standby evaporator tube 7 and the horizontal plane is 40°.

[0038] In this embodiment, the inclination angle of the top nozzle of the liquid blocking section 9 is relatively large, the end of the liquid blocking sect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap