Silicon nitride ceramic heating ignition device of particle barbecue oven

A furnace silicon nitride, ceramic heating technology, applied in the direction of combustion ignition, lighting and heating equipment, combustion methods, etc., can solve the problems of economic loss, life safety, shell leakage, heat transfer reduction, etc., to improve the scope of ignition, guarantee Cleanliness, the effect of increasing the amount of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

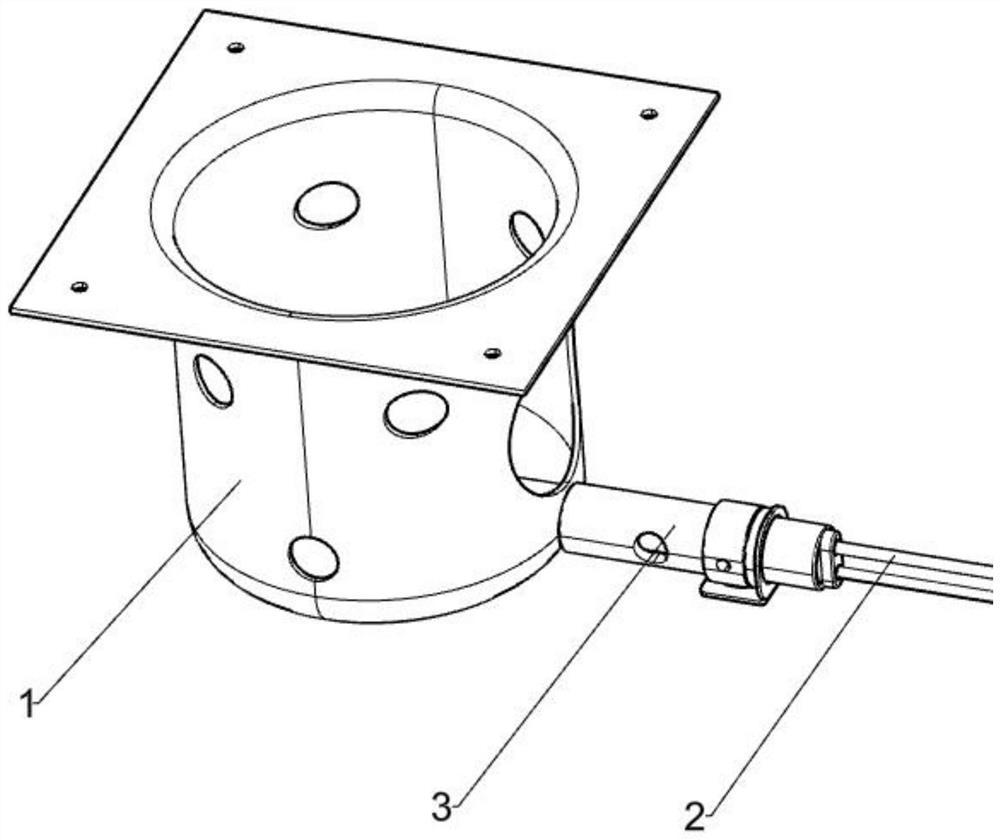

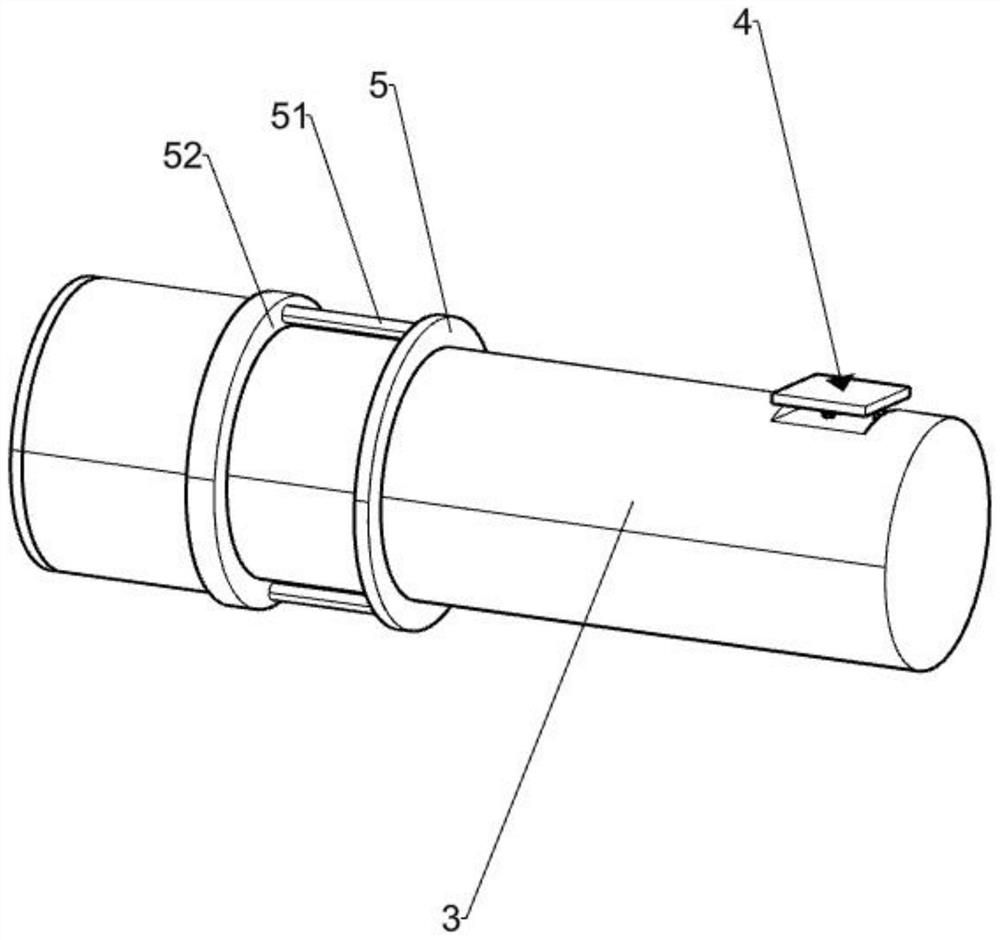

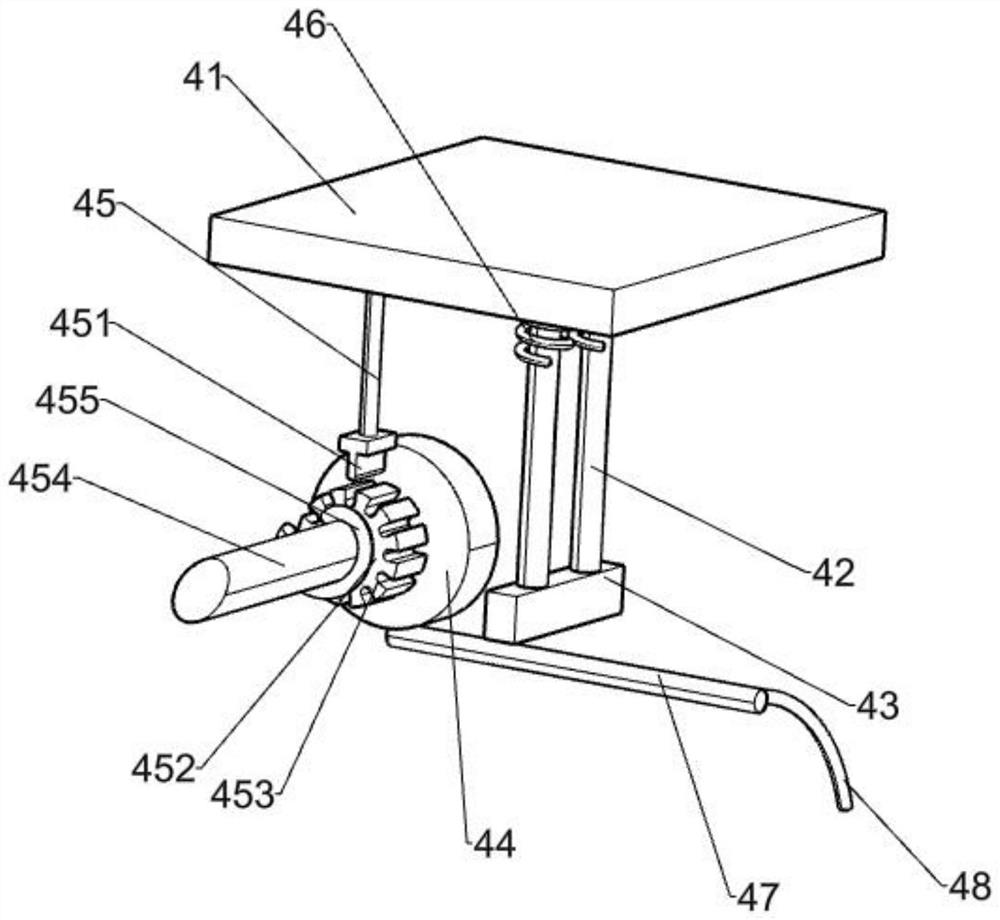

[0040] Such as Figure 1-17As shown, an ignition device for heating silicon nitride ceramics for a granular barbecue furnace is characterized in that it includes a stove 1, a protective shell 3 fixedly connected to the stove 1 and partly located inside the stove 1, and a protective shell 3 fixedly connected to the stove 1. The protective shell 3 conducts the conductive wire 2, the rotary tube 53 that is connected to the protective shell 3 and is arranged inside the stove 1, the ceramic ignition rod 9 that is arranged inside the rotary tube 53 and the protective shell 3 for igniting the stove 1, The cleaning structure 6 used to clean the ceramic ignition rod 9, which is locate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap