A process and device for blowing off and recovering workpiece surface material liquid with circulating compressed gas

A technology of workpiece surface and circulating gas, applied in the directions of drying gas arrangement, transportation and packaging, drying of solid materials, etc., can solve the problems of zero emission, increased processing investment and processing cost, and cost increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

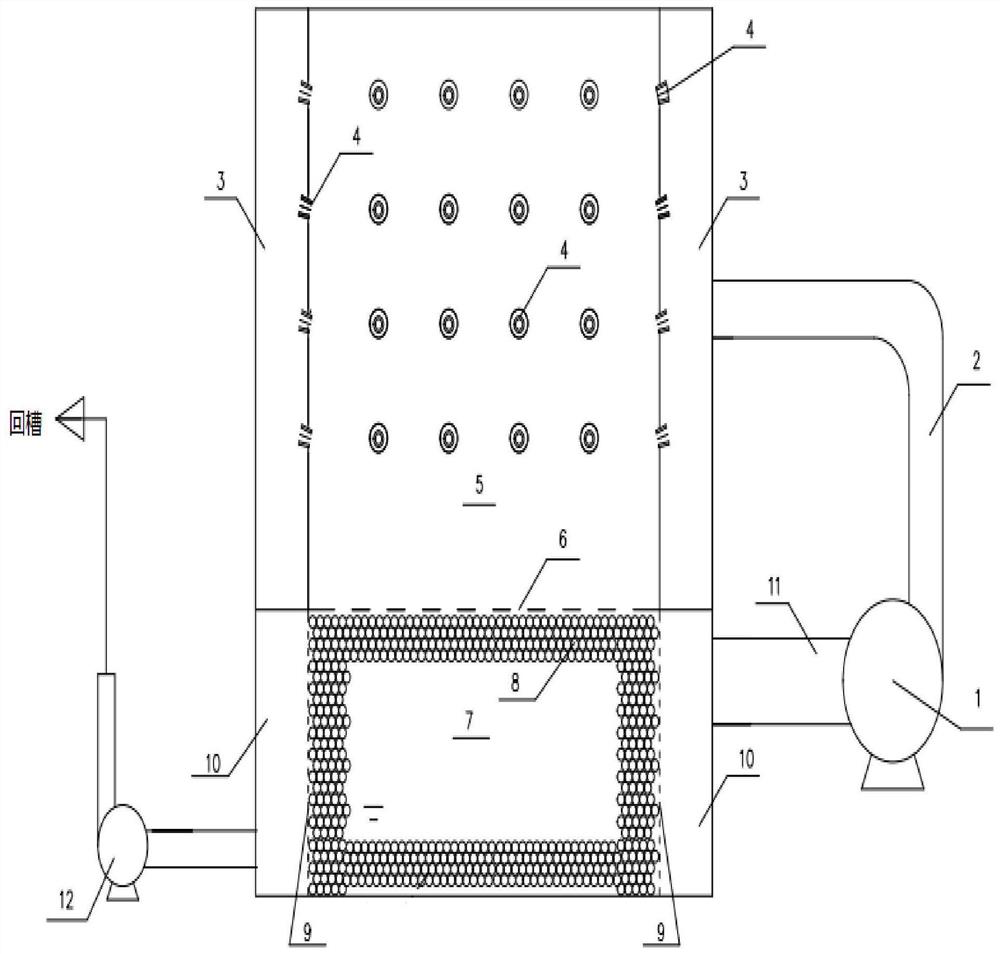

[0033] The invention provides a device for blowing off and recovering the material liquid of surface workpieces with circulating compressed gas, which comprises a circulating gas pressurization unit 1; The recovery material liquid lifting unit 12 in which the liquid pipe is connected to the stripping unit;

[0034] The blow-off unit includes a pressurized gas air chamber 3, a blowing port 4, a blow-off chamber 5, an air guide orifice plate 6, a gas-liquid separation chamber 7, a filter material 8, an air guide net 9 and an exhaust air chamber 10;

[0035] The circulating gas pressurization unit includes a supercharger; the air inlet of the supercharger is connected to the exhaust port of the exhaust air chamber, and the air outlet of the supercharger is connected to the inlet of the compressed gas air chamber;

[0036] The outer wall of the pressurized gas air chamber 3 is the same outer wall as that of the blow-off unit; the blow-off chamber is also provided with an air inlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap