Flexible bearing noise test platform based on harmonic vibration

A flexible bearing and noise testing technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as high noise, achieve good data visualization and improve loading convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

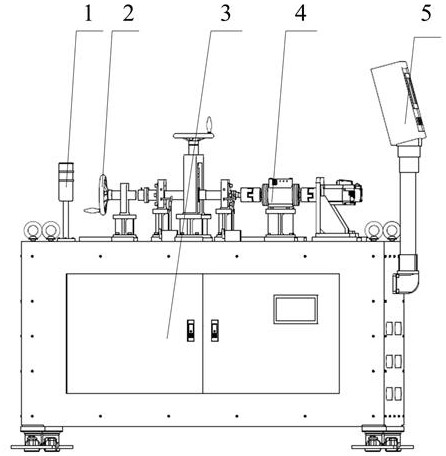

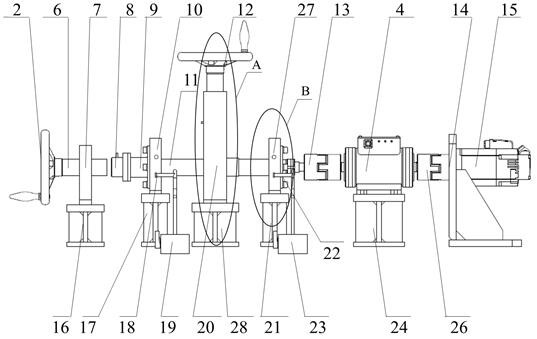

[0021] The invention provides a flexible bearing noise test platform based on harmonic vibration, such as Figure 1-4 As shown, the flexible bearing noise test platform is composed of five main parts: alarm system 1, loading system, data acquisition system, sensor and electrical control platform 5, wherein:

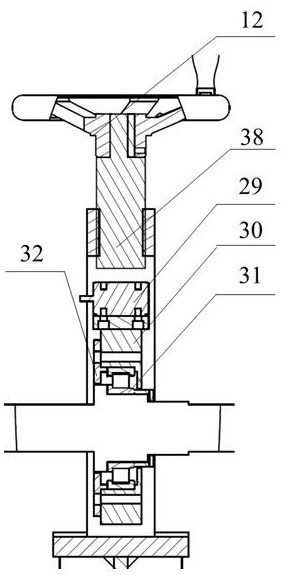

[0022] The sensors include a torque sensor 4 , an axial force sensor 8 , a radial force sensor 29 , a microphone sensor one 18 , and a microphone sensor two 22 .

[0023] The sensor is connected with the data acquisition system, and the data acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com