Double-sided heat dissipation power module and packaging method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

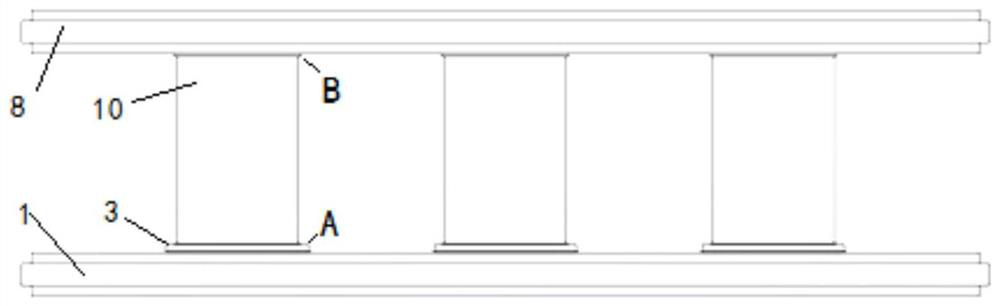

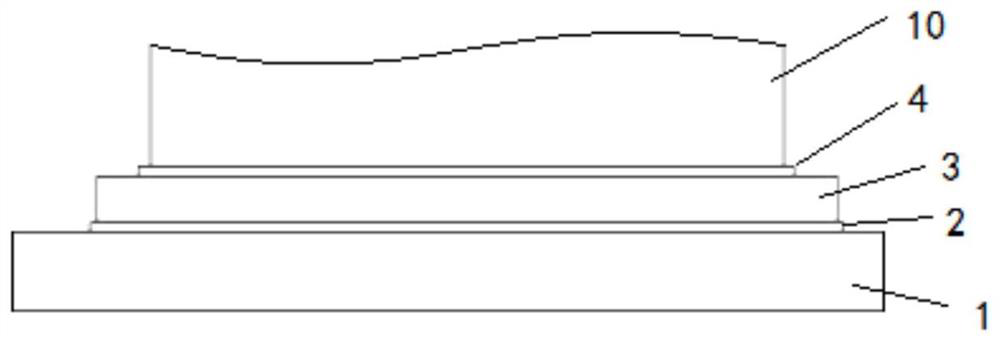

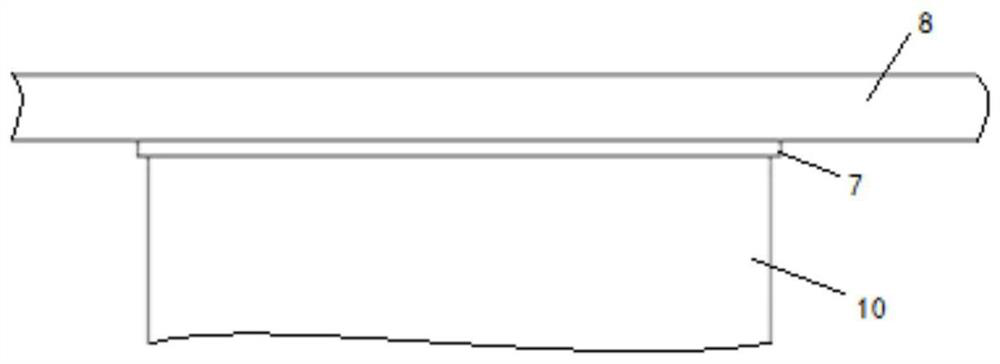

[0040] Such as Figure 4 As shown, the double-sided heat dissipation power module of this embodiment includes a power chip 3, an upper backing board 8, a lower backing board 1 and a spacer assembly 5, and one side of the power chip 3 is connected to the lower backing board 1 through the first connection layer 2. The other side of the power chip 3 is connected to one end of the spacer assembly 5 through the second connection layer 4, and the other end of the spacer assembly 5 is connected to the upper liner 8 through the third connection layer 7; wherein the spacer assembly 5 includes The first spacer 501 and the second spacer 502, one end of the first spacer 501 is connected to the power chip 3 through the second connection layer 4, and the other end of the first spacer 501 is detachably connected to one end of the second spacer 502 , the other end of the second pad 502 is connected to the upper liner 8 through the third connection layer 7 . The double-sided heat dissipation ...

Embodiment 2

[0059] The difference between this embodiment and the first embodiment lies in that the shapes of the bump 601 and the groove 602 are different. Specifically, the bump 601 is convex, and the groove 602 matches the bump 601 to be convex. The specific process is:

[0060] Connect the power chip 3 to the lower substrate 1 through the first connection layer 2, and then connect the first spacer 501 (with bump 601) on the power chip 3 through the second connection layer 4; The second pad 502 (with groove 602) is connected to the upper liner 8; the above three connection processes are reflow soldering or sintering processes, and the thickness of the connecting layer in the above three reflow soldering or sintering processes does not need to be specially increased. Thick; after completing the three-step connection, connect the first spacer 501 and the second spacer 502 of the two parts of the product by sliding, because the protrusions 601 and grooves 602 of each spacer cooperate wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com