Laminated battery pole core assembly, laminated battery and preparation process

A battery pole, laminated technology, applied in battery pack parts, large flat battery/battery, secondary battery manufacturing, etc. Connection stability, weight reduction, improved deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

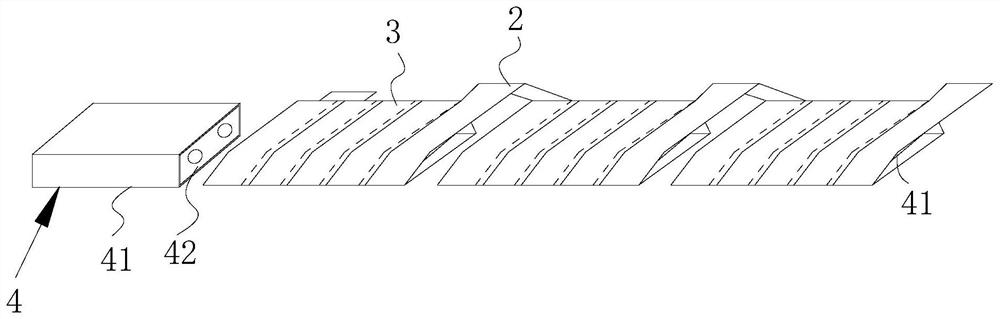

[0084] Further, see Figure 8 , as a specific embodiment of the preparation process of a laminated battery core assembly provided by the present invention, the following steps are included after step S3-3:

[0085] The pole core winding at the end surface of the pole core on which the pole core winding is spirally wound is subjected to a cutting process by a cutting process.

[0086] The pole core winding body not wound on the pole core is cut through the above steps.

[0087] Specifically, the cutting process is a laser cutting process or a blade cutting process, the cutting process is preferably a laser cutting process, and the cutting process can be performed without contacting the pole core winding at the end face of the pole core spirally wound with the pole core winding , to reduce the impact on the pole core winding on the pole core.

[0088] Optimally, the laser cutting process is realized by a laser cutting device.

[0089] Further, see Figure 8 , as a specific e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com