Power battery pack and vehicle

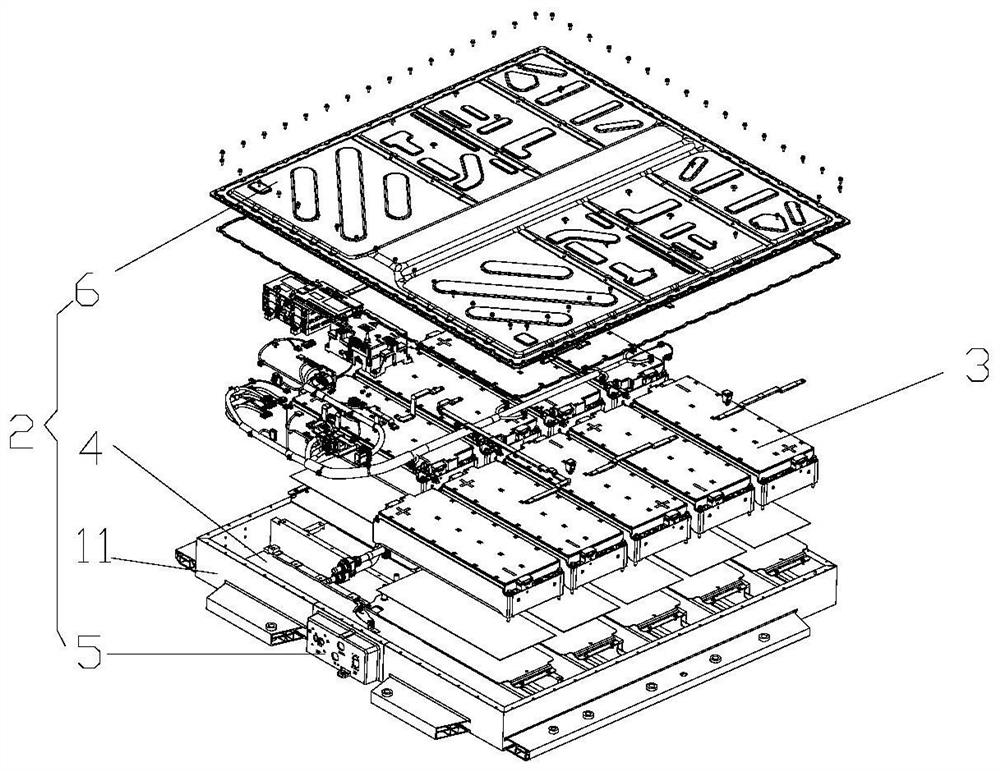

A power battery pack and vehicle body technology, applied in the field of vehicles, can solve the problems of low space utilization and difficult assembly, and achieve the effects of easy production and processing, minimized installation clearance, and eliminated adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

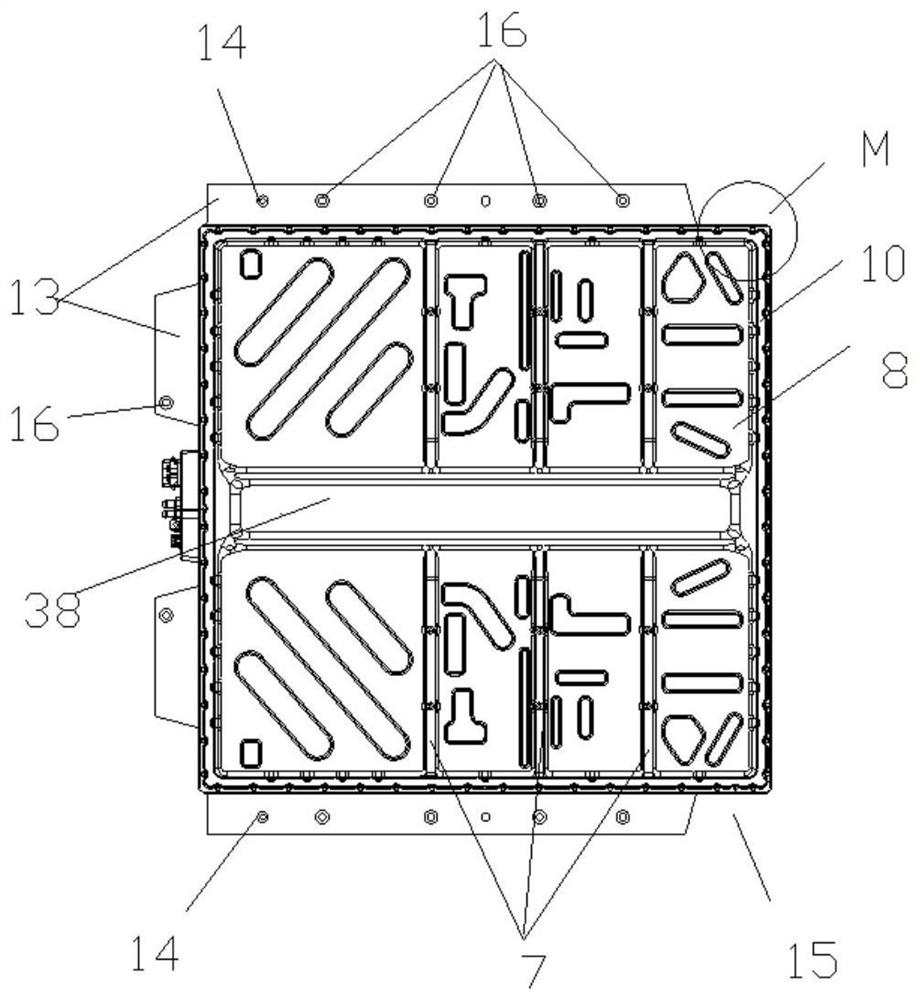

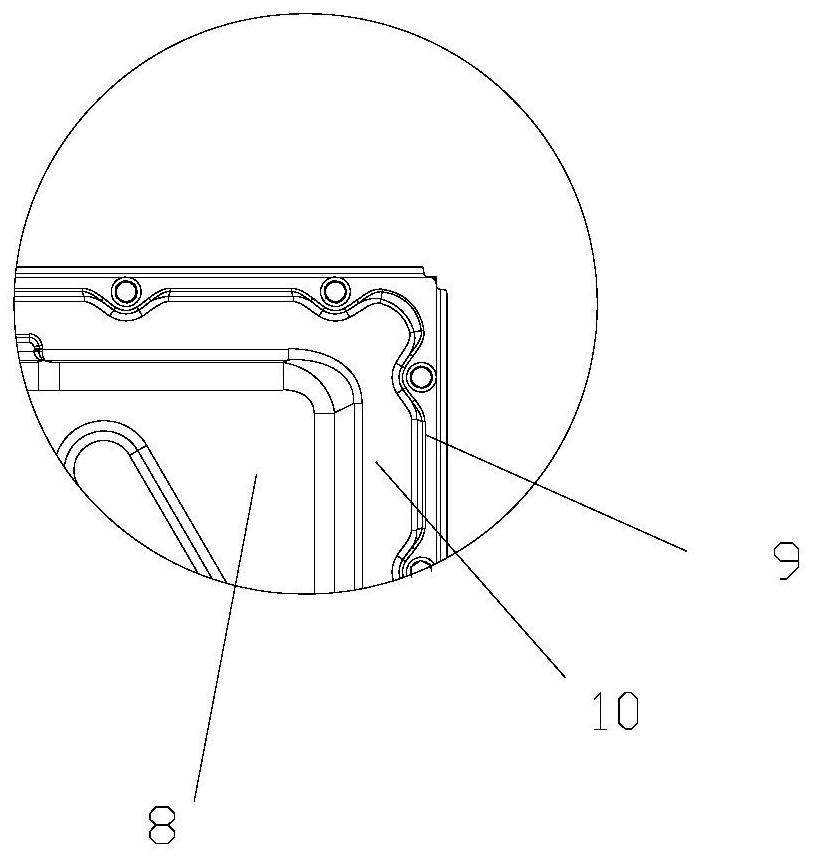

[0066] According to yet another specific embodiment of the present invention, the plate body 8 includes a plurality of recesses 7 that are recessed downwards, and the recesses 7 are configured to be able to bear against the top wall of the beam 1 to be assembled with the beam 1 , the structure is simple, which is conducive to improving the assembly strength between the shell and the beam, and optimizing the protection effect of the power battery pack. Further, the recess 7 can be provided with a plurality of installation holes at intervals, and the top wall of the beam 1 includes a plurality of installation points corresponding to the plurality of installation holes, so as to be assembled to the installation points of the beam 1 by fasteners such as bolts. , which improves the assembly strength between the upper shell and the beam.

[0067] According to another specific embodiment of the present invention, such as Figure 7 As shown, the side beam includes a transverse beam 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com