Canned saline tuna containing various trace elements and processing technology of canned saline tuna

A technology of trace elements and processing technology, which is applied in the direction of using inorganic salts to preserve meat/fish, food ingredients as antimicrobial preservation, and the function of food ingredients. Fresh and tender, not conducive to the health of the eater, etc., to achieve the effect of good health, easy digestion and absorption, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

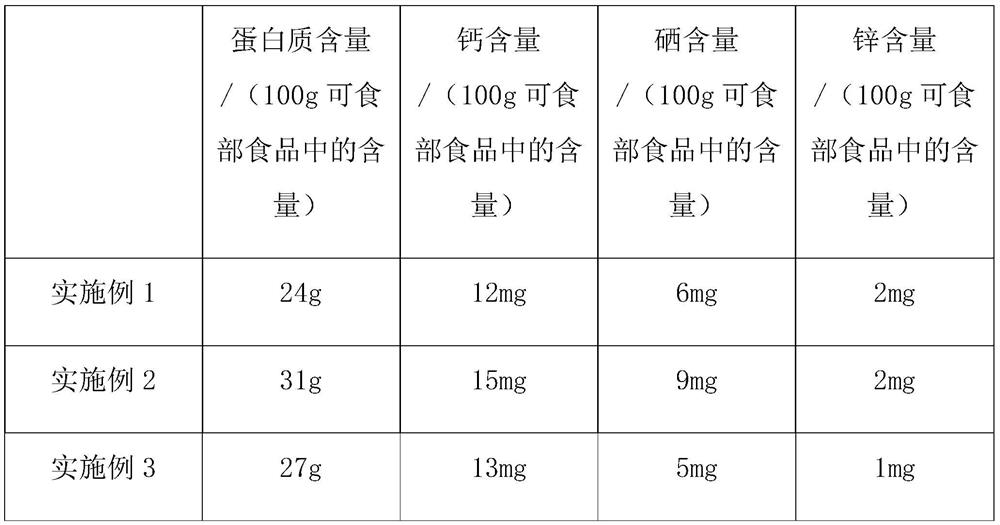

Embodiment 1

[0033] A saltwater canned tuna containing various trace elements. The formula includes: sesame oil, tuna, cooking wine, eggs, refined salt, soy sauce, brown sugar, ginger slices and minced garlic. The mass percentages of each component are: 25 parts of sesame oil , 60 parts of tuna, 15 parts of cooking wine, 10 parts of eggs, 5 parts of refined salt, 10 parts of soy sauce, 2 parts of brown sugar, 4 parts of ginger slices and 1 part of minced garlic.

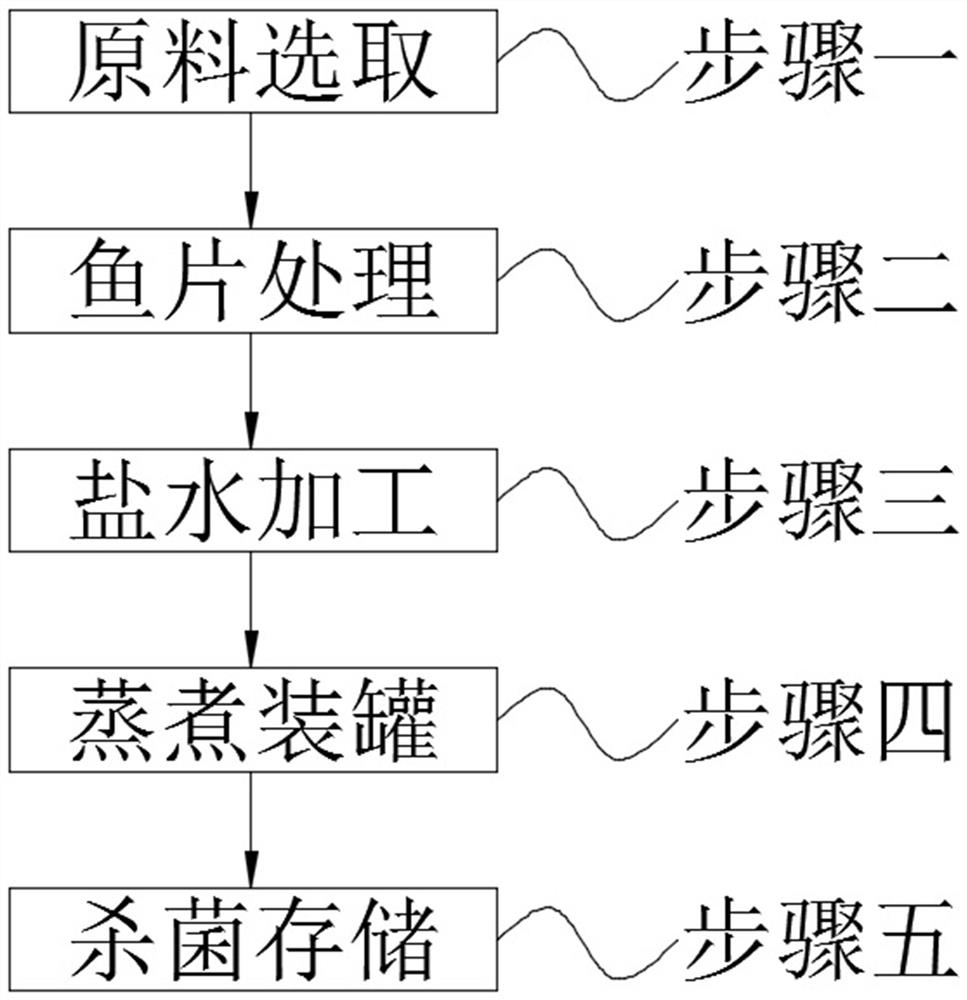

[0034] A processing technology for canned tuna in salt water containing various trace elements, comprising the following steps: Step 1, raw material selection; Step 2, fish fillet processing; Step 3, brine processing; Step 4, steaming and canning; Step 5, sterilizing and storing ;

[0035] Wherein the above-mentioned step 1, according to the mass percentage content of each component is respectively: 20 parts of sesame oil, 60 parts of tuna, 20 parts of cooking wine, 10 parts of eggs, 5 parts of refined salt, 10 parts of soy sauce...

Embodiment 2

[0050] A canned tuna in salt water containing various trace elements, the formula comprising: sesame oil, tuna, cooking wine, eggs, refined salt, soy sauce, brown sugar, sliced ginger and minced garlic, the mass percentages of each component are: 20 parts of sesame oil , 60 parts of tuna, 20 parts of cooking wine, 10 parts of eggs, 5 parts of refined salt, 10 parts of soy sauce, 2 parts of brown sugar, 4 parts of ginger slices and 1 part of minced garlic.

[0051] A processing technology for canned tuna in salt water containing various trace elements, comprising the following steps: Step 1, raw material selection; Step 2, fish fillet processing; Step 3, brine processing; Step 4, steaming and canning; Step 5, sterilizing and storing ;

[0052] Wherein the above-mentioned step 1, according to the mass percentage content of each component is respectively: 20 parts of sesame oil, 60 parts of tuna, 20 parts of cooking wine, 10 parts of eggs, 5 parts of refined salt, 10 parts of s...

Embodiment 3

[0067] A canned tuna in salt water containing various trace elements, the formula comprising: sesame oil, tuna, cooking wine, eggs, refined salt, soy sauce, brown sugar, sliced ginger and minced garlic, the mass percentages of each component are: 15 parts of sesame oil , 60 parts of tuna, 25 parts of cooking wine, 10 parts of eggs, 5 parts of refined salt, 10 parts of soy sauce, 2 parts of brown sugar, 4 parts of ginger slices and 1 part of minced garlic.

[0068] A processing technology for canned tuna in salt water containing various trace elements, comprising the following steps: Step 1, raw material selection; Step 2, fish fillet processing; Step 3, brine processing; Step 4, steaming and canning; Step 5, sterilizing and storing ;

[0069] Wherein the above-mentioned step 1, according to the mass percentage content of each component is respectively: 20 parts of sesame oil, 60 parts of tuna, 20 parts of cooking wine, 10 parts of eggs, 5 parts of refined salt, 10 parts of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com